Reinforcing member for vehicle backdoor inner plate

A reinforcement and back door technology, which is applied in the field of reinforcement of the inner panel of the vehicle back door, can solve the problems of poor dimensional accuracy, heavy quality, and complicated injection molding process molds, etc., to achieve stability improvement, ensure mechanical performance, and improve design sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

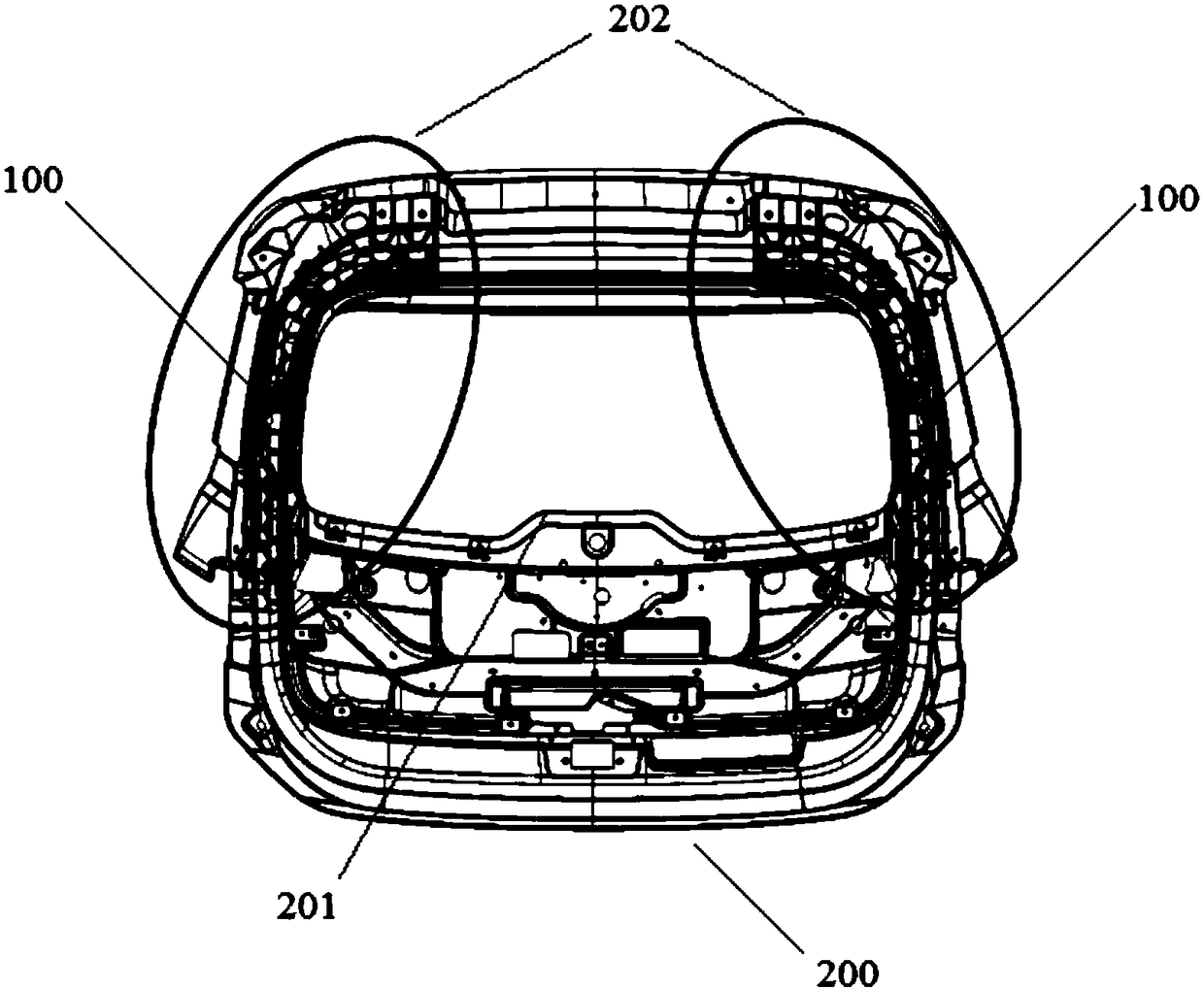

[0026] According to a preferred embodiment of the present invention, there is provided a reinforcement for a vehicle back door inner panel, such as figure 1 As shown, the figure also shows the reinforcement member 100 and the vehicle back door inner panel 200 assembled together.

[0027] Wherein, the vehicle back door inner panel 200 includes a windshield mounting hole 201 above it, and D-pillar regions 202 located on both sides of the windshield mounting hole 201, as shown in FIG. figure 1 Shown by the circled part in .

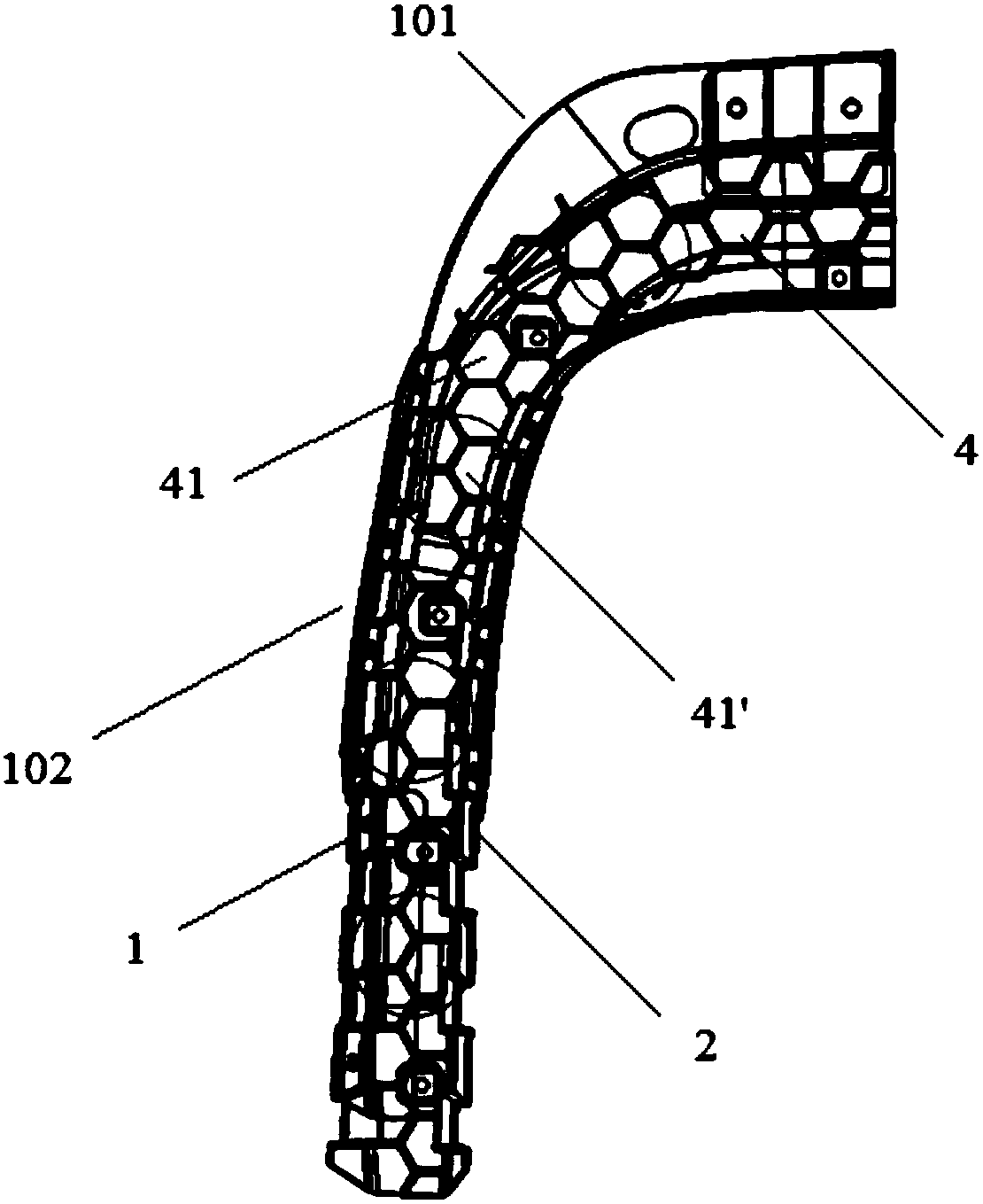

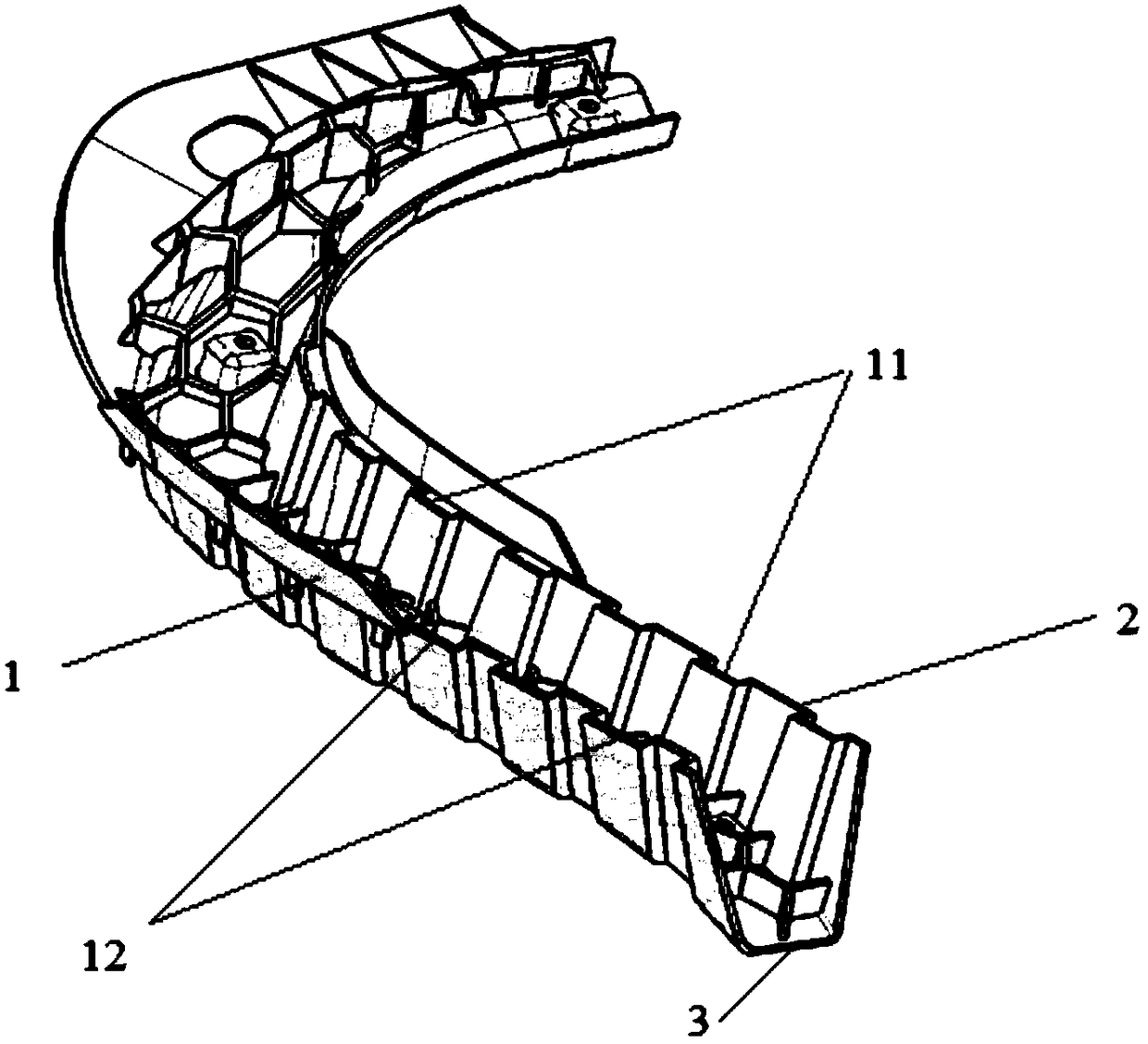

[0028] The reinforcement 100 includes a pair of reinforcements (eg, figure 1 parts with deepened lines as shown in ), such as figure 2 As shown, each reinforcing member is divided into a bent secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com