Method of promoting bioleaching of copper pyrites by adding nonionic surfactant

A non-ionic surface, bioleaching technology, applied in the direction of improving process efficiency, can solve the problems of low leaching rate and slow leaching speed, and achieve the effect of low price, stable performance and weakening passivation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Crushing and grinding the chalcopyrite ore sample to -0.074mm, and then sterilizing it with ultraviolet light, as a leaching sample;

[0034] (2) Thiobacillus ferrooxidans was grown to the logarithmic phase in 9K medium, the culture solution was filtered to remove the alum precipitate, and the bacteria were collected by centrifugation for 15 minutes (10000r / min) as the leaching inoculum.

[0035] (3) Place the leaching sample in the sterilized 9K basic salt solution, the concentration of the leaching sample in the solution is 1g / 100mL, insert Thiobacillus ferrooxidans, and adjust the initial bacterial concentration to 1×10 7 pcs / mL, then add polyethylene glycol, the amount of polyethylene glycol added is 30mg / L, and dilute sulfuric acid is used to adjust the initial pH of leaching to 1.8;

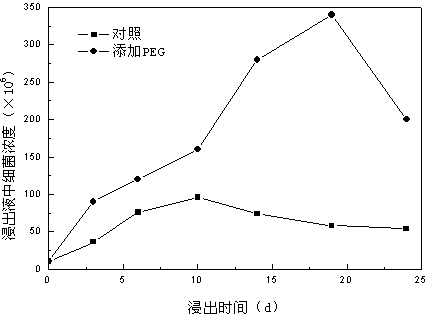

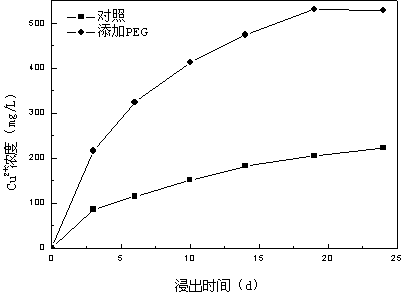

[0036] (4) Under the conditions of 30°C and 150r / min, place the above leachate in an air bath constant temperature oscillator and oscillate for 24 days. Use a hemocytometer to co...

Embodiment 2

[0046] (1) Crushing and grinding the chalcopyrite ore sample to -0.074mm, and then sterilizing it with ultraviolet light, as a leaching sample;

[0047] (2) Thiobacillus ferrooxidans was grown to the logarithmic phase in 9K medium, the culture solution was filtered to remove the alum precipitate, and the bacteria were collected by centrifugation for 15 minutes (10000r / min) as the leaching inoculum.

[0048] (3) Place the leaching sample in the sterilized 9K basic salt solution, the concentration of the leaching sample in the solution is 2g / 100mL, insert Thiobacillus ferrooxidans, and adjust the initial bacterial concentration to 3×10 7 each / mL, then add polyethylene glycol, the amount of polyethylene glycol added is 50mg / L, and dilute sulfuric acid is used to adjust the initial pH of leaching to 2.5;

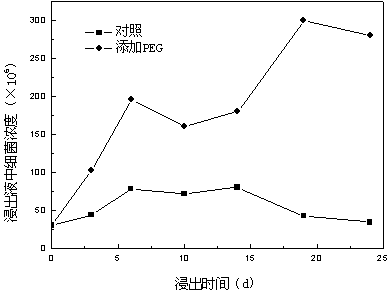

[0049] (4) Under the conditions of 25°C and 180r / min, place the above leaching solution in an air bath constant temperature oscillator and oscillate for 24 days. Use a hemocytom...

Embodiment 3

[0057] (1) Crushing and grinding the chalcopyrite ore sample to -0.074mm, and then sterilizing it with ultraviolet light, as a leaching sample;

[0058] (2) Thiobacillus ferrooxidans was grown to the logarithmic phase in 9K medium, the culture solution was filtered to remove the alum precipitate, and the bacteria were collected by centrifugation for 15 minutes (10000r / min) as the leaching inoculum.

[0059] (3) Place the leaching sample in the sterilized 9K basic salt solution, the concentration of the leaching sample in the solution is 1g / 100mL, insert Thiobacillus ferrooxidans, and adjust the initial bacterial concentration to 5×10 7 pcs / mL, add 9g / L Fe 2+ , then add polyethylene glycol, the amount of polyethylene glycol added is 90mg / L, and dilute sulfuric acid is used to adjust the initial pH of leaching to 3.0;

[0060] (4) Under the conditions of 35°C and 160r / min, place the above-mentioned leachate in an air bath constant temperature oscillator and oscillate for 18 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com