Preparation method and application of alumina-loaded nano ferrous sulfide composite material

An alumina-loaded, ferrous sulfide technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. Nano-iron sulfides are easy to agglomerate and other problems, and the preparation method is simple and efficient, the preparation cycle is short, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

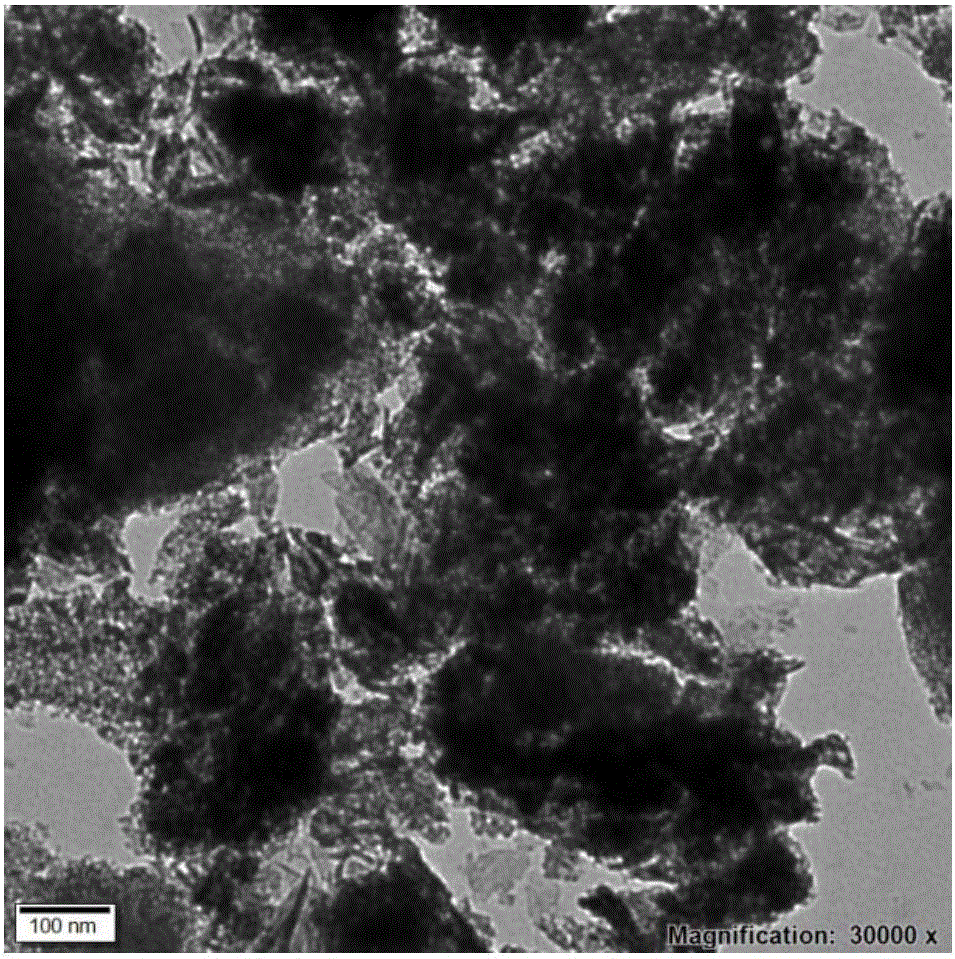

[0030] Example 1: Preparation of alumina-loaded nano-ferrous sulfide composite material (loading capacity 30%, that is, the mass percentage of ferrous sulfide and alumina is 3:7)

[0031] (1) Alumina carrier pretreatment: Grind the purchased alumina to 100 mesh, soak in 5% nitric acid solution for 30 minutes to remove surface impurities, then wash with deionized water until neutral, and dry in an oven at 110°C for 12 hours, Calcined at 400°C for 4 hours, and finally passed through a 100-mesh sieve to obtain a pretreated alumina carrier.

[0032] (2) Prepare ferrous sulfide particles: weigh 2.105g Na 2 S·9H 2 O and 5g PEG4000 were dissolved in 50mL of deionized water, and the solution was transferred to a 250mL three-necked flask, and the flow rate was 150mL / min under N 2 Ultrasonic dispersion was carried out for 30min under atmosphere (rotational speed was 300r / min); at the same time, another 250mL three-neck flask was filled with deionized water, and the flow rate was 200mL...

Embodiment 2

[0041] Embodiment 2: the preparation of aluminum oxide loaded nano ferrous sulfide composite material (loading capacity 20%)

[0042] (1) The pretreatment of the alumina carrier is as described in step (1) in Example 1.

[0043] (2) The preparation of ferrous sulfide particles is described in step (2) in Example 1. The difference is the addition of Na 2 S·9H 2 O and FeSO 4 ·7H 2 The amounts of O were 1.365 g and 1.580 g, respectively.

[0044] (3) Preparation of alumina-loaded nano-ferrous sulfide composite material is the same as that described in step (3) in Example 1. The difference is that γ-Al 2 o 3 The dosage is 2g.

Embodiment 3

[0045] Embodiment 3: the preparation of alumina-loaded nano ferrous sulfide composite material (loading capacity 40%)

[0046] (1) The pretreatment of the alumina carrier is as described in step (1) in Example 1.

[0047] (2) The preparation of ferrous sulfide particles is described in step (2) in Example 1. The difference is the addition of Na 2 S·9H 2 O and FeSO 4 ·7H 2 The amounts of O are 2.729 g and 3.159 g, respectively.

[0048] (3) Preparation of alumina-loaded nano-ferrous sulfide composite material is the same as that described in step (3) in Example 1. The difference is that γ-Al 2 o 3 The dosage is 1.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com