Method for inhibiting generation of ferrous oxide in high iron zinc calcine reduction roasting process by utilizing partial pressure of CO2

A technology for ferrous oxide and high iron zinc is applied in the field of selective reduction and selective reduction of zinc ferrite in high iron zinc calcined sand, which can solve the problems of difficult recycling of iron slag, large amount of leaching slag, difficulty in separation of iron and zinc, etc. Easy roasting conditions, low equipment corrosion, and the effect of simplifying the zinc hydrometallurgy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

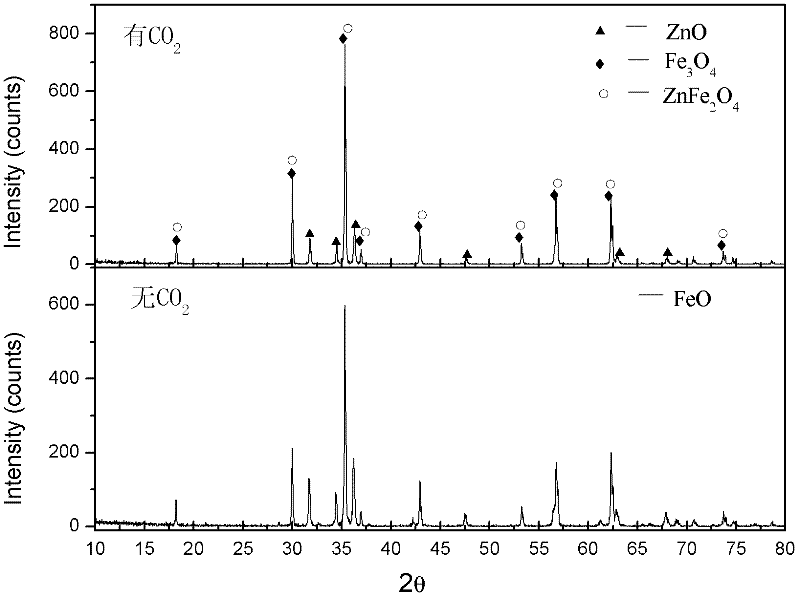

[0023] Zinc ferrite is dried and then ground and sieved until particles with a particle size of less than 75 μm account for more than 95%. 2 Reduction roasting under the condition of 60min, 750℃, CO, Ar and CO 2 The mixed gas; where the CO concentration is 4%, CO / (CO+CO 2 ) is reduction roasting under 20% condition for 60min, and the flow rate of the mixed gas is controlled at 0.065L / g·min (the flow rate of the mixed gas refers to the volume of the mixed gas required per unit mass of zinc ferrite per unit time). The results show that the decomposition of zinc ferrite occurs during the reduction roasting process, but in the absence of CO 2 Under the roasting conditions, there is ferrous oxide generated, and CO 2 In the future, iron mainly exists in the phase form of magnetic ferroferric oxide. It can be seen that CO 2 The addition of avoids the Fe 3 o 4 +CO=FeO+CO 2 The occurrence of the reaction can effectively avoid subsequent leaching of a large amount of iron.

Embodiment 2

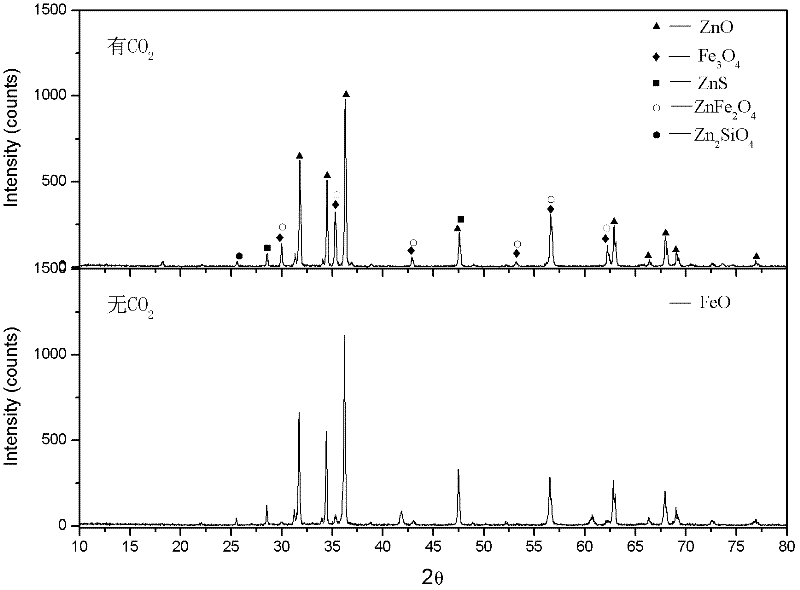

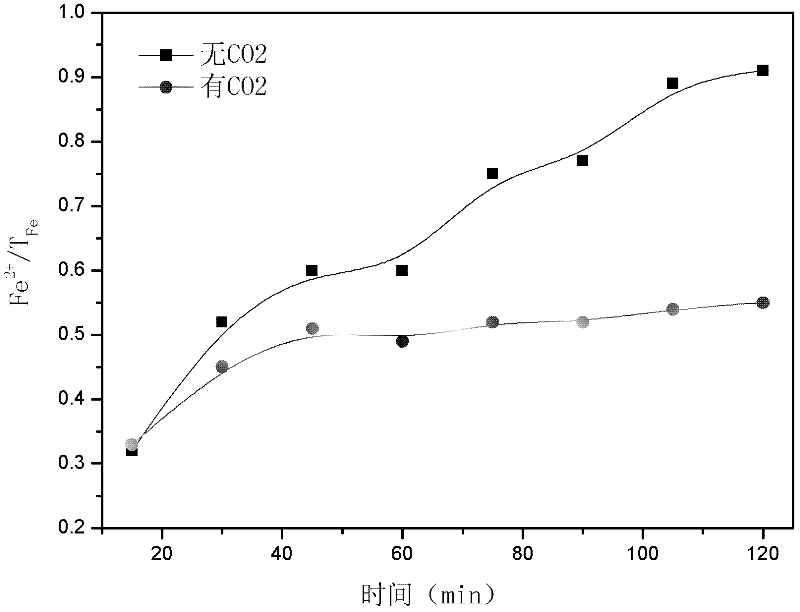

[0025] After the high-iron-zinc calcine pretreatment, respectively, at 750 ° C, CO concentration 4%, no CO 2 Under the conditions, reduction roasting 60min, 750℃, CO, Ar and CO 2 The mixed gas; where the CO concentration is 4%, CO / (CO+CO 2 ) is reduced and roasted for 60 minutes under the condition of 20%, and according to the zinc ferrite content, the flow rate of the mixed reducing gas is controlled to be 0.0176L / g min (the mixed gas flow rate refers to the required mixing rate of zinc ferrite per unit time in unit time). The volume of the gas in which the percentage of zinc ferrite α is 0.27). Fe was analyzed after reduction roasting 2+ / T Fe Variations over time such as image 3 shown. The results showed that the zinc ferrite in the high iron zinc calcine was decomposed during the reduction roasting process, and the zinc ferrite was transformed into zinc oxide and magnetic ferroferric oxide. without CO 2 Under the calcination conditions, zinc ferrite is over-reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com