Gas fuel oxygen-carried hydrogen-produced and carbon dioxide separation method and device

A carbon dioxide and gas fuel technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of large equipment investment and high energy consumption, and achieve the effect of simple device structure, reduced energy consumption, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

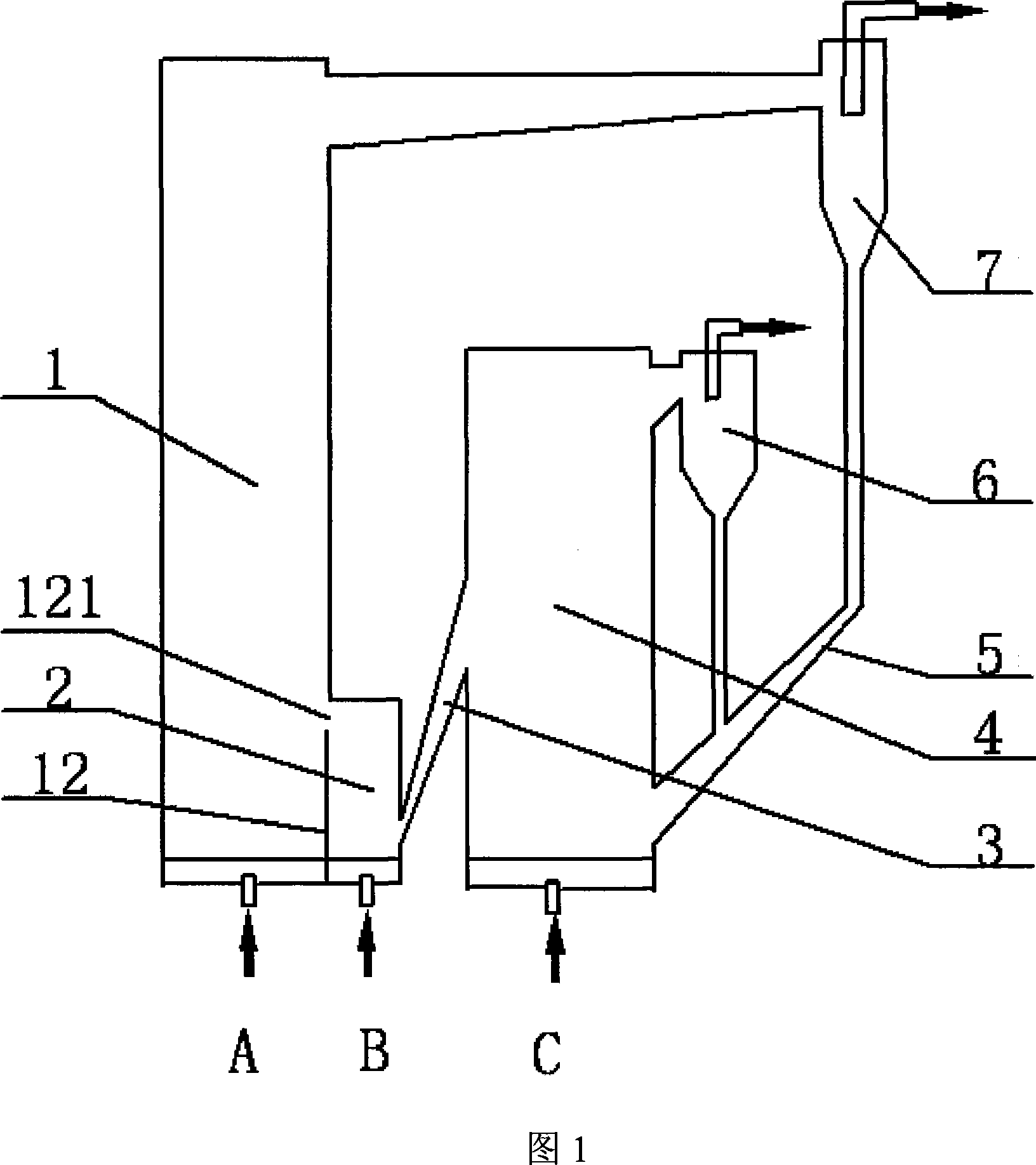

[0022] The principle, technical process and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Fig. 1 is a schematic diagram of the principle and structure of an embodiment of a gaseous fuel-carrying oxygen production hydrogen and carbon dioxide separation device provided by the present invention. The device comprises a circulating fluidized bed 1, a moving bed 2, a bubbling fluidized bed 4, a hydrogen separator 7, a carbon dioxide separator 6, and the hydrogen separator 7 is arranged at the outlet on the upper part of the circulating fluidized bed, and the hydrogen The bottom of the separator is connected with the lower part of the bubbling fluidized bed 4 through the return leg 5; the carbon dioxide separator 6 is arranged at the outlet of the upper part of the bubbling fluidized bed 4, and the bottom of the separator is connected with the return leg . Both the hydrogen separator 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com