Preparation method for composite material with micro/nano core-shell structure

A nano-core-shell and composite material technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as cumbersome process, and achieve the effects of environmental protection, non-toxic reagents, short processing time, and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Take by weighing 0.1g tannic acid solid, dissolve in 2.5ml water, prepare the tannic acid aqueous solution that concentration is 40mg / ml;

[0041] (2) Take by weighing 0.025g ferric chloride solid, be dissolved in 2.5ml water, the preparation concentration is the ferric chloride aqueous solution of 10mg / ml;

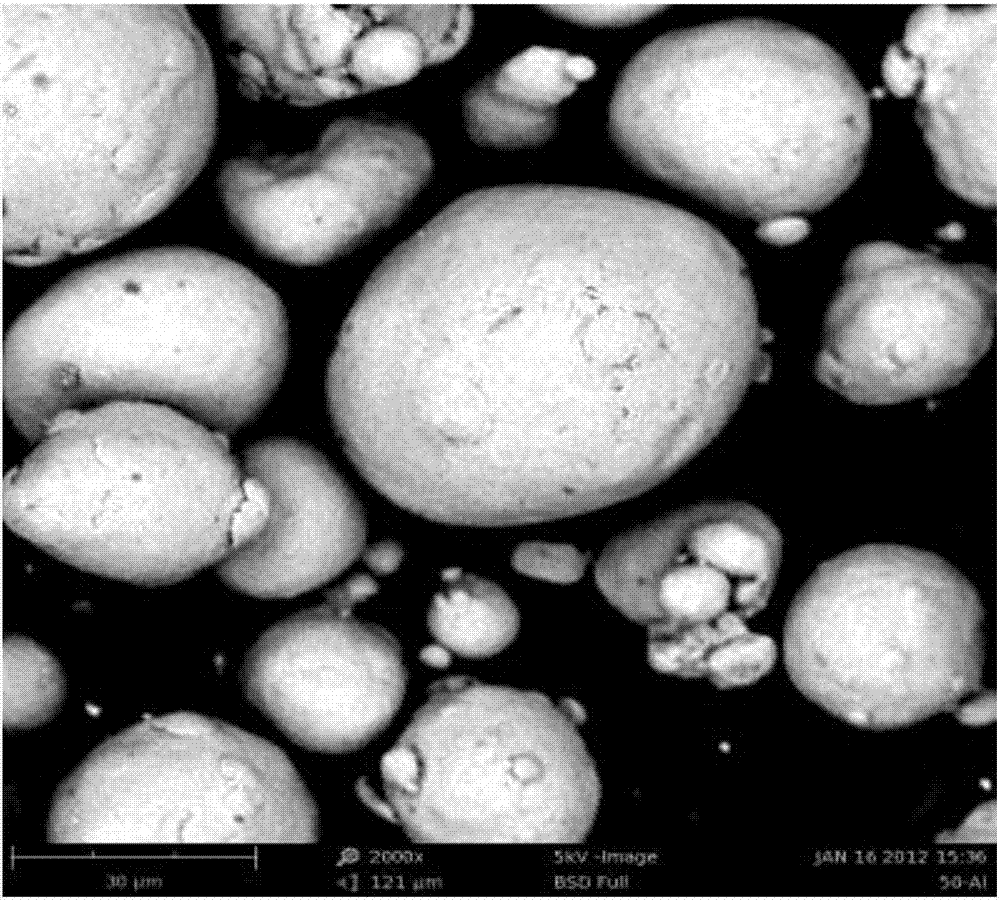

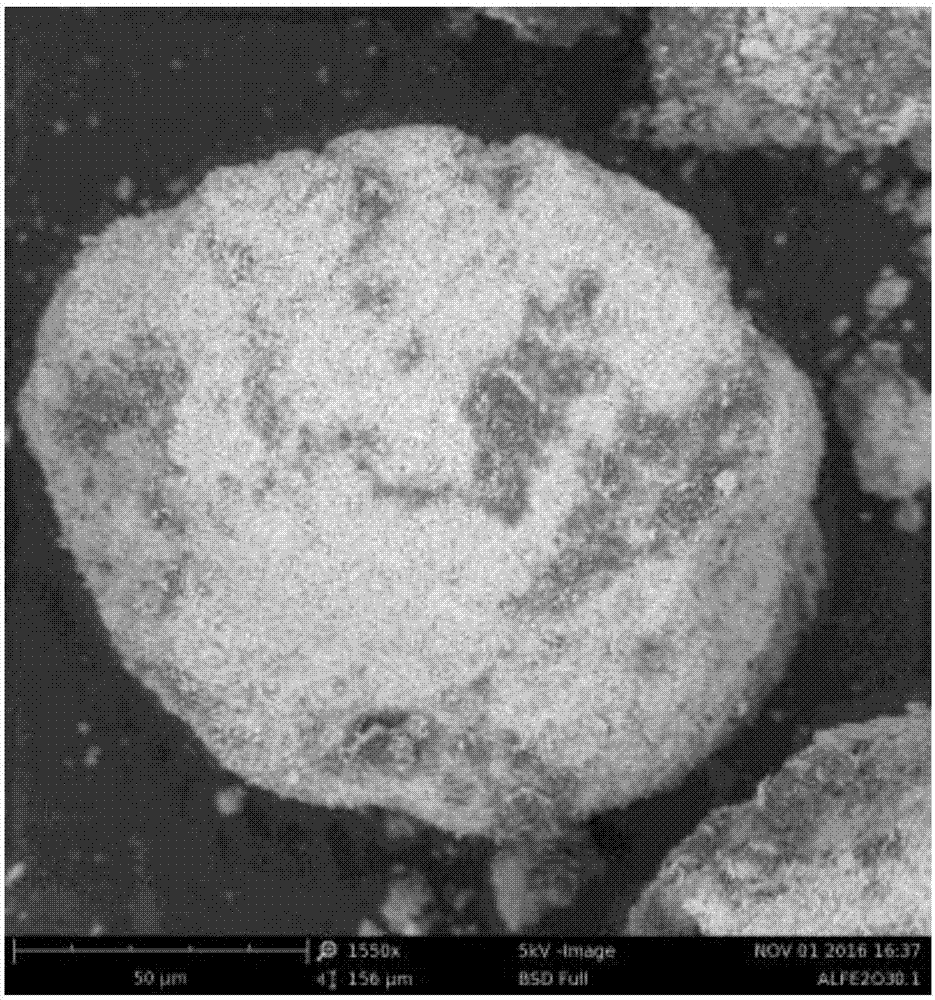

[0042] (3) Weigh 1g such as figure 1 Add the aluminum powder shown in the tannic acid aqueous solution and stir rapidly, the stirring speed is 500r / min, the stirring time is 100s, the solution temperature is 70°C, after the stirring is completed, filter and separate the metal particles; weigh 1g of ferric oxide powder and add trichloride Stir rapidly in the aqueous iron solution, the stirring rate is 500r / min, the stirring time is 100s, the solution temperature is 70°C, and the metal oxide particles are separated by filtration after the stirring is completed;

[0043] (4) Disperse the pretreated aluminum powder particles and ferric oxide powder particles in wa...

Embodiment 2

[0045] (1) Weigh 0.1g dopamine solid, dissolve it in 20ml water, and prepare a dopamine aqueous solution with a concentration of 5mg / ml;

[0046] (2) Take by weighing 0.1g ferric chloride solid, be dissolved in 20ml water, prepare the ferric chloride aqueous solution that concentration is 5mg / ml;

[0047](3) Weigh 2g of copper powder and add it to the dopamine aqueous solution for rapid stirring, the stirring rate is 600r / min, the stirring time is 300s, and the solution temperature is 60°C. After the stirring is completed, the copper powder particles are separated by filtration; Stir rapidly in the ferric chloride aqueous solution, the stirring rate is 600r / min, the stirring time is 300s, the solution temperature is 50°C, after the stirring is completed, filter and separate the ferric oxide particles;

[0048] (4) disperse the pretreated copper powder and ferric oxide powder in the water and stir rapidly in the water, the stirring rate is 400r / min, add dropwise the potassium h...

Embodiment 3

[0050] (1) Take by weighing 0.1g tea polyphenol solid, dissolve in 2.5ml water, prepare the tea polyphenol aqueous solution that concentration is 40mg / ml;

[0051] (2) Take by weighing 0.025g ferric chloride solid, be dissolved in 2.5ml water, the preparation concentration is the ferric chloride aqueous solution of 10mg / ml;

[0052] (3) Add 1g of copper oxide powder into the tea polyphenol aqueous solution and stir quickly, the stirring rate is 400r / min, the stirring time is 400s, the solution temperature is 50°C, after the stirring is completed, filter and separate the copper oxide particles; weigh 1g of aluminum powder and add trichloro Stir rapidly in the ferric chloride aqueous solution, the stirring rate is 400r / min, the stirring time is 400s, the solution temperature is 50°C, after the stirring is completed, filter and separate the aluminum powder particles;

[0053] (4) Disperse the pretreated aluminum powder and copper oxide powder in the water and stir rapidly at a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com