Conjugated micro-porous polymer and preparation method thereof

A technology of conjugated microporous polymers, which is applied in the field of conjugated microporous polymers and their preparation, can solve the problems of high cost and complicated preparation process, and achieve the effect of good thermal stability and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a conjugated microporous polymer, comprising the following steps:

[0030] Mix tetraketone, trialdehyde compound, o-dichlorobenzene and n-butanol, and carry out the first polymerization reaction under the protection of nitrogen to obtain the first polymerization product system; the trialdehyde compound is trisaldehyde or trialdehyde Phloroglucinol;

[0031] The first polymerization product system is mixed with acetic acid, and the second polymerization reaction is carried out under nitrogen protection to obtain a conjugated microporous polymer.

[0032] In the present invention, tetraketone, trialdehyde compound, o-dichlorobenzene and n-butanol are mixed, and the first polymerization reaction is carried out under the protection of nitrogen to obtain the first polymerization product system; Aldehydophloroglucinol. In the present invention, the tetraketone is preferably symmetric indacene-1,3,5,7(2H,6H)-tetraketone. In the...

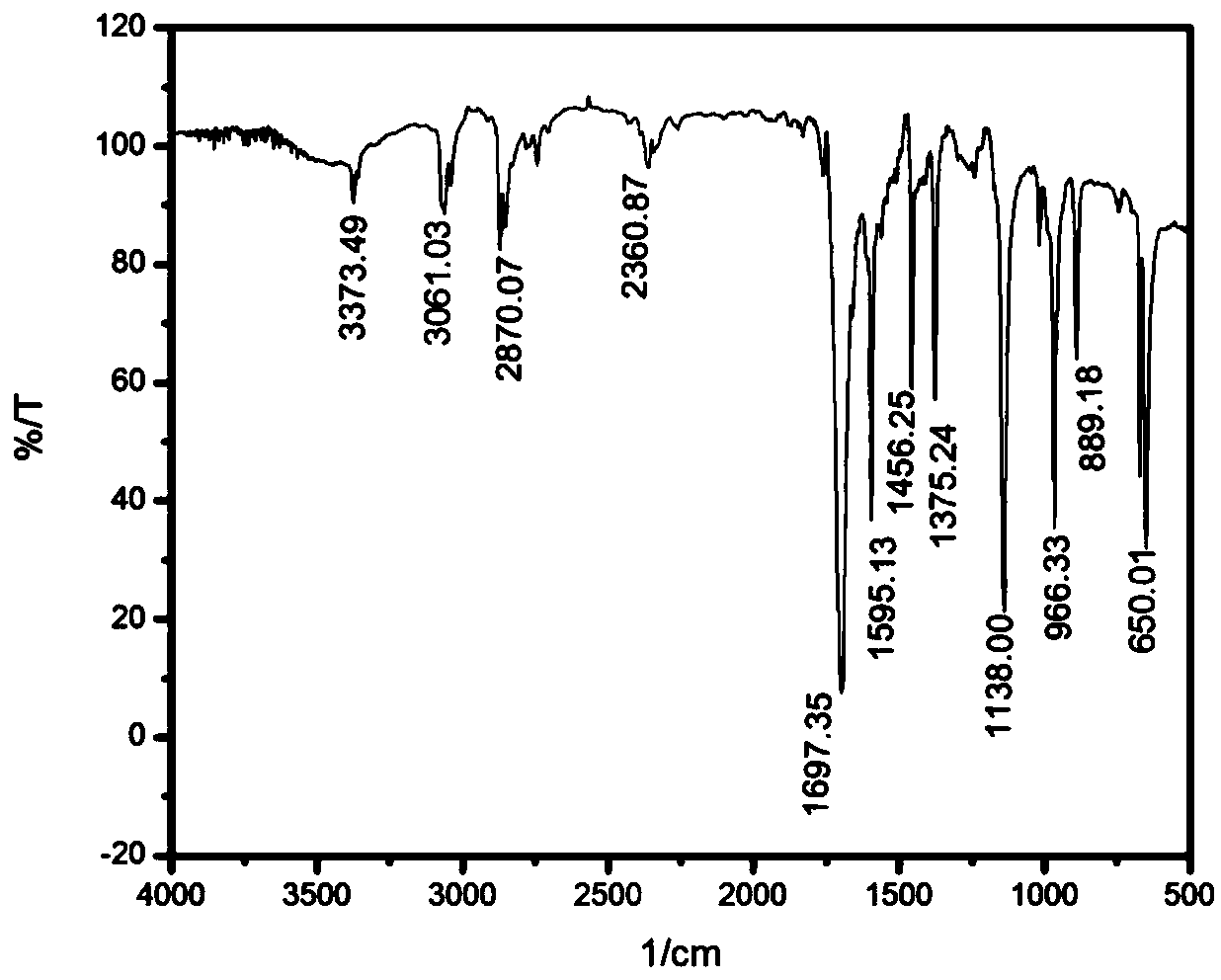

Embodiment 1

[0046] Pour trimethylene triformaldehyde and tetraketone into a single-necked flask with a molar ratio of 2:3, put a magnet, then add o-dichlorobenzene and n-butanol, the volume ratio of the two is 7:3, then vacuumize and fill with N 2 , repeated three times, turn on the magnetic stirrer, 2Stir for 20 minutes under ambient conditions, carry out the first polymerization reaction, and obtain the first polymerization product system; then, add acetic acid to the first polymerization reaction system, so that the volume ratio of o-dichlorobenzene, n-butanol and acetic acid is 7:3:1, The second polymerization reaction 3d was carried out at 120° C. under stirring conditions. After the reaction was completed, a black flaky substance appeared in the reaction flask. The three-neck flask was removed, cooled to room temperature, and poured into a Buchner funnel for filtration. After filtration, the product was rinsed with ethanol three times, and the filter cake was poured into a small bea...

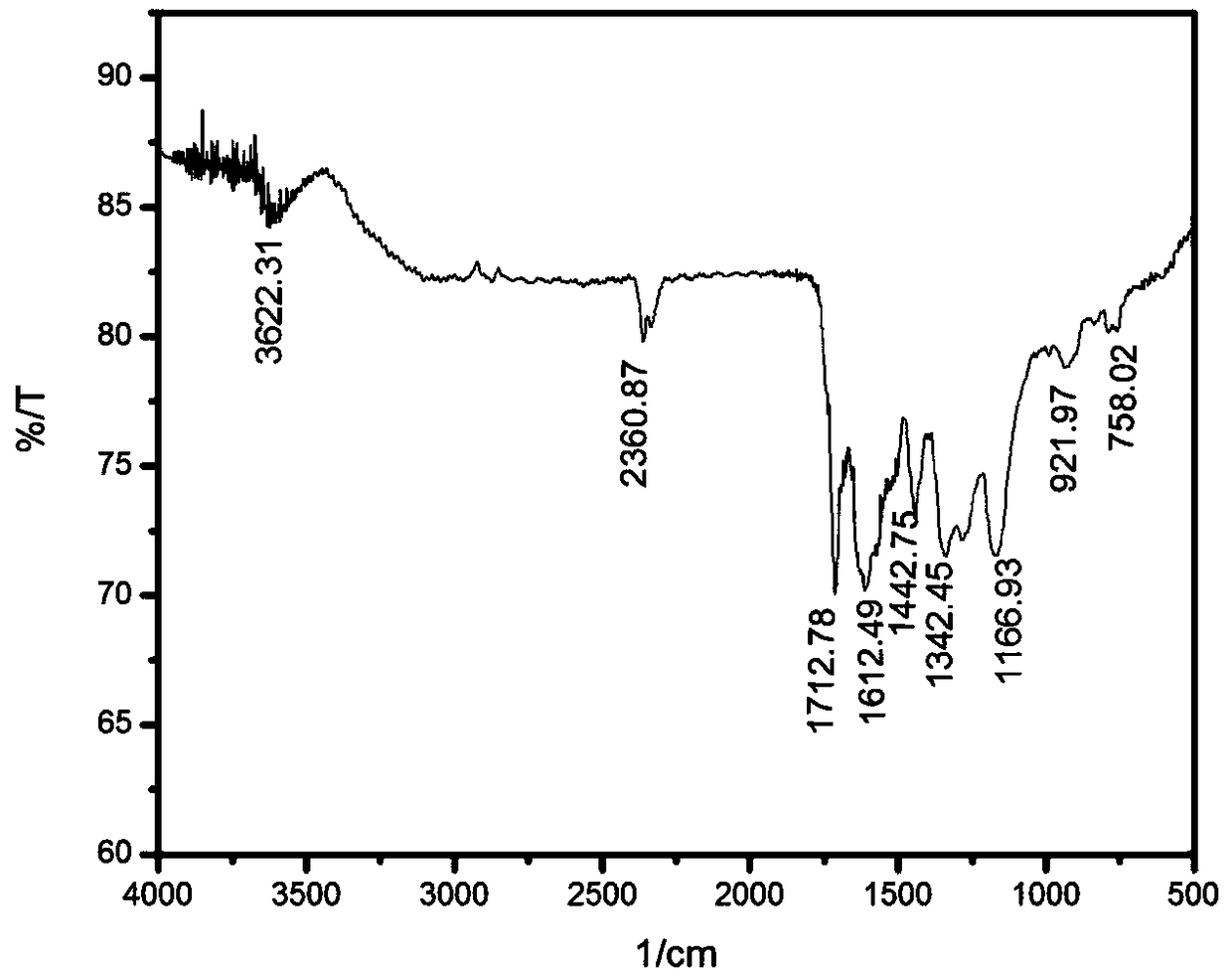

Embodiment 2

[0048] Pour trialdehyde phloroglucinol and tetraketone into a single-necked flask with a molar ratio of 2:3, put a magnet, then add o-dichlorobenzene and n-butanol, the volume ratio of the two is 7:3, and then vacuumize. Charge N 2 , repeated three times, turn on the magnetic stirrer, 2 Stir for 20 minutes under ambient conditions, carry out the first polymerization reaction, and obtain the first polymerization product system; then add acetic acid to the first polymerization reaction system, so that the volume ratio of o-dichlorobenzene, n-butanol and acetic acid is 7:3:1, in The second polymerization reaction 3d was carried out at 120° C. under stirring conditions. After the reaction was completed, a black flaky substance appeared in the reaction flask. The three-neck flask was removed, cooled to room temperature, and poured into a Buchner funnel for filtration. After filtration, the product was rinsed with ethanol three times, and the filter cake was poured into a small bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com