Silver phosphate/titanium dioxide nanocomposite and preparation method thereof

A nano-composite material, titanium dioxide technology, applied in the field of nano-composite material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

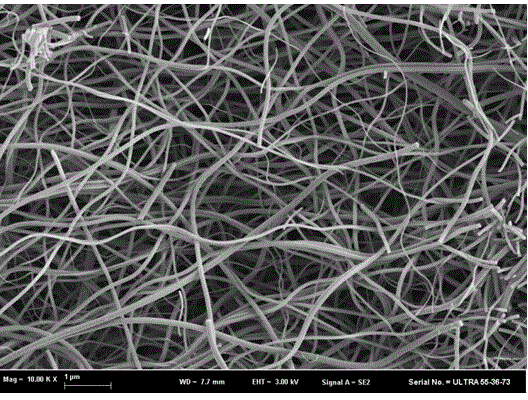

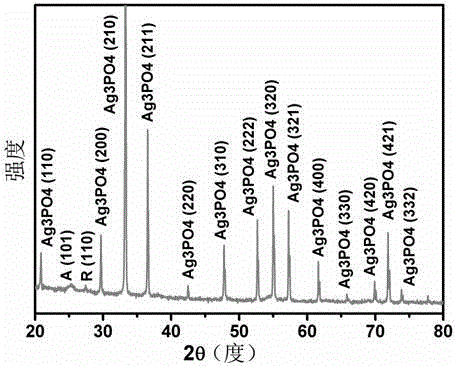

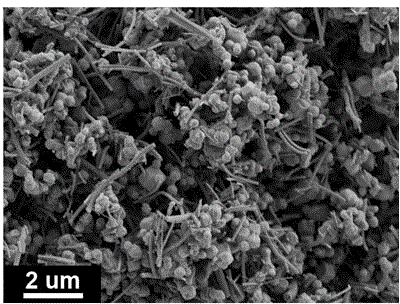

[0031] 1) Add 0.684 g PVP to 6 mL DMF solvent, add 1 mL acetic acid and 1 g butyl titanate, and stir magnetically for 12 h to obtain spinning solution. The above solution was put into a syringe for electrospinning, the flow rate of the solution was set at 0.6 mL / h, the collection distance was 14 cm, and the voltage was 15 kV. The fiber film collected on the receiving plate was put into a muffle furnace for sintering, and the temperature was raised to 500 °C at a rate of 1 °C / min, then kept for 3 h, and cooled to obtain titanium dioxide nanofibers;

[0032] 2) Take 0.08 g of titanium dioxide nanofibers obtained in step 1) and ultrasonically disperse them in 50 mL of deionized water; take 3 mmol of silver nitrate and dissolve them in the above dispersion liquid, and mix for 2 h under the condition of avoiding light and stirring;

[0033] 3) Dissolve 1 mmol of sodium dihydrogen phosphate in 50 mL of deionized water, add it dropwise to the solution obtained in step 2) under the co...

Embodiment 2

[0038] 1) Add 0.684 g PVP to 6 mL DMF solvent, add 1.5 mL acetic acid and 1.368 g butyl titanate, and stir magnetically for 15 h to obtain spinning solution. The above solution was put into a syringe for electrospinning, the flow rate of the solution was set at 0.8 mL / h, the collection distance was 20 cm, and the voltage was 18 kV. Put the fiber film collected on the receiving plate into a muffle furnace for sintering, raise the temperature to 550 °C at a rate of 2 °C / min, keep it for 2 h, and cool to obtain titanium dioxide nanofibers;

[0039]2) Take 0.2 g of titanium dioxide nanofibers obtained in step 1) and ultrasonically disperse them in 80 mL of deionized water; take 1.5 mmol of silver acetate and dissolve them in the above dispersion, and mix for 1 h under the condition of avoiding light and stirring;

[0040] 3) Dissolve 0.5 mmol of potassium dihydrogen phosphate in 50 mL of deionized water, add it dropwise to the solution obtained in step 2) under the condition of av...

Embodiment 3

[0042] 1) Add 0.684 g of PVP to 6 mL of DMF solvent, add 0.9 mL of dilute hydrochloric acid and 0.684 g of butyl titanate, and stir magnetically for 10 h to obtain a spinning solution. The above solution was put into a syringe for electrospinning, the flow rate of the solution was set at 0.5 mL / h, the collection distance was 10 cm, and the voltage was 10 kV. Put the fiber film collected on the receiving plate into a muffle furnace for sintering, raise the temperature to 450°C at a rate of 1.5°C / min, keep it warm for 3 hours, and cool to obtain titanium dioxide nanofibers;

[0043] 2) Take 0.05 g of titanium dioxide obtained in step 1) and ultrasonically disperse it in 100 mL of deionized water; add the silver nitrate ammonium solution containing 3 mmol of silver ammonium ions to the above dispersion, and mix for 1 h under the condition of avoiding light and stirring;

[0044] 3) Dissolve 1 mmol of sodium dihydrogen phosphate in 2 ml of deionized water, add it dropwise to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com