High-strength temperature-sensitive hydrogel as well as preparation method and application thereof

A hydrogel, high-strength technology, applied in the direction of using carriers to introduce foreign genetic material, cells modified by introducing foreign genetic material, recombinant DNA technology, etc., can solve high tensile and compression resistance functions, lack of DNA adsorption capacity Cell attachment and detachment ability and other issues, to achieve the effect of strong tensile and compression resistance, easy long-term storage and long-distance transportation, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

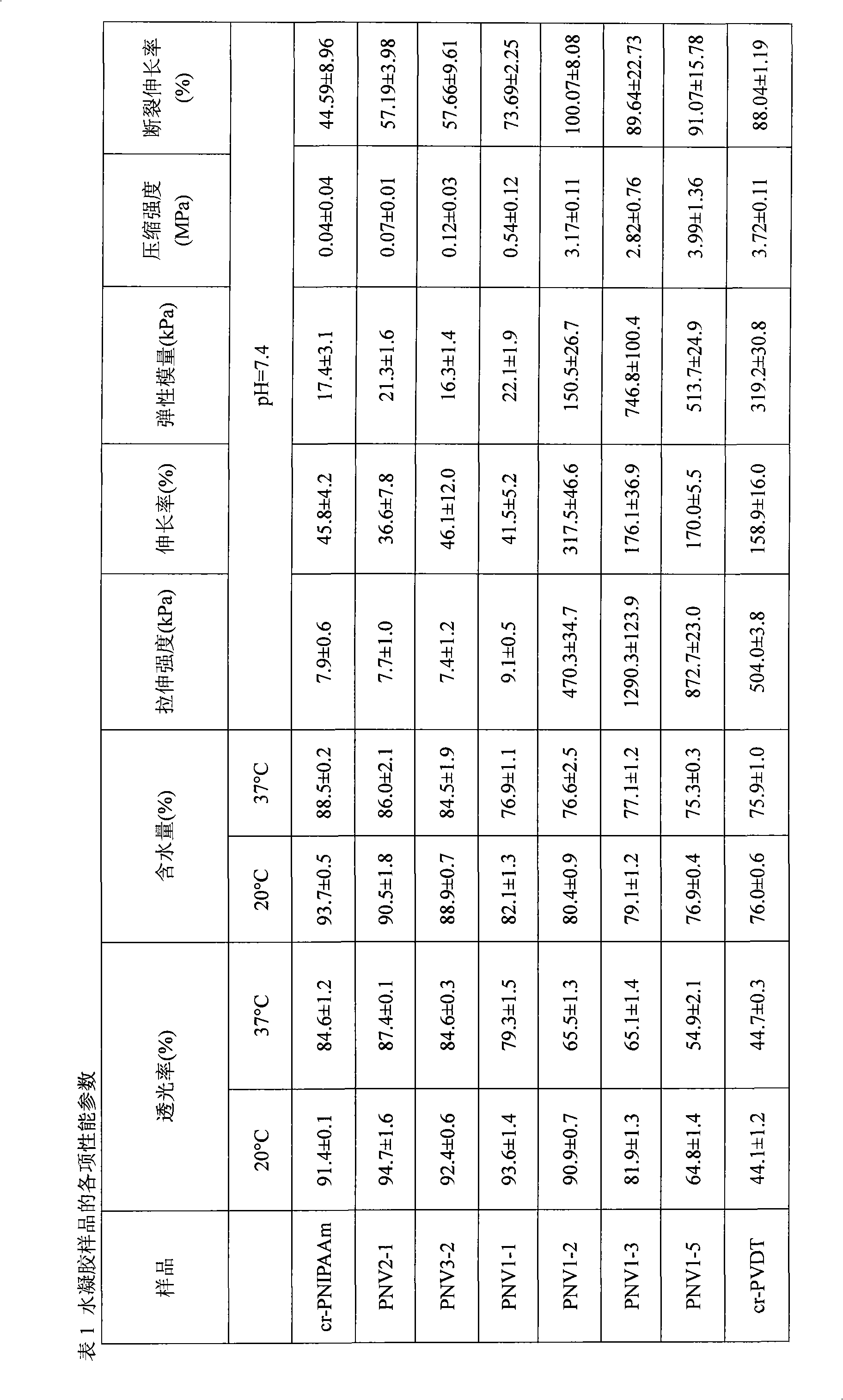

[0021]The monomer N-isopropylacrylamide (8mg), 2-vinyl-4,6-diamino-1,3,5-triazine (4mg) and the cross-linking agent polyethylene glycol diacrylate (8mg , molecular weight 575, the same below) was added to a 1.5ml centrifuge tube, after dissolving monomer and crosslinking agent with 200μl DMSO, adding photoinitiator Irgacure 2959 (0.4mg, 1-[4-(2-hydroxyethoxy )-phenylene]-2-hydroxy-2',2'-dimethylethanone). A solvent containing monomers, crosslinking agents and initiators was injected into a closed mold, and the mold was irradiated in a UV curing box for 20 minutes to initiate free radical polymerization. Then the mold was opened to take out the gel, rinsed several times with deionized water, soaked for 7 days, and replaced the deionized water every 12 hours.

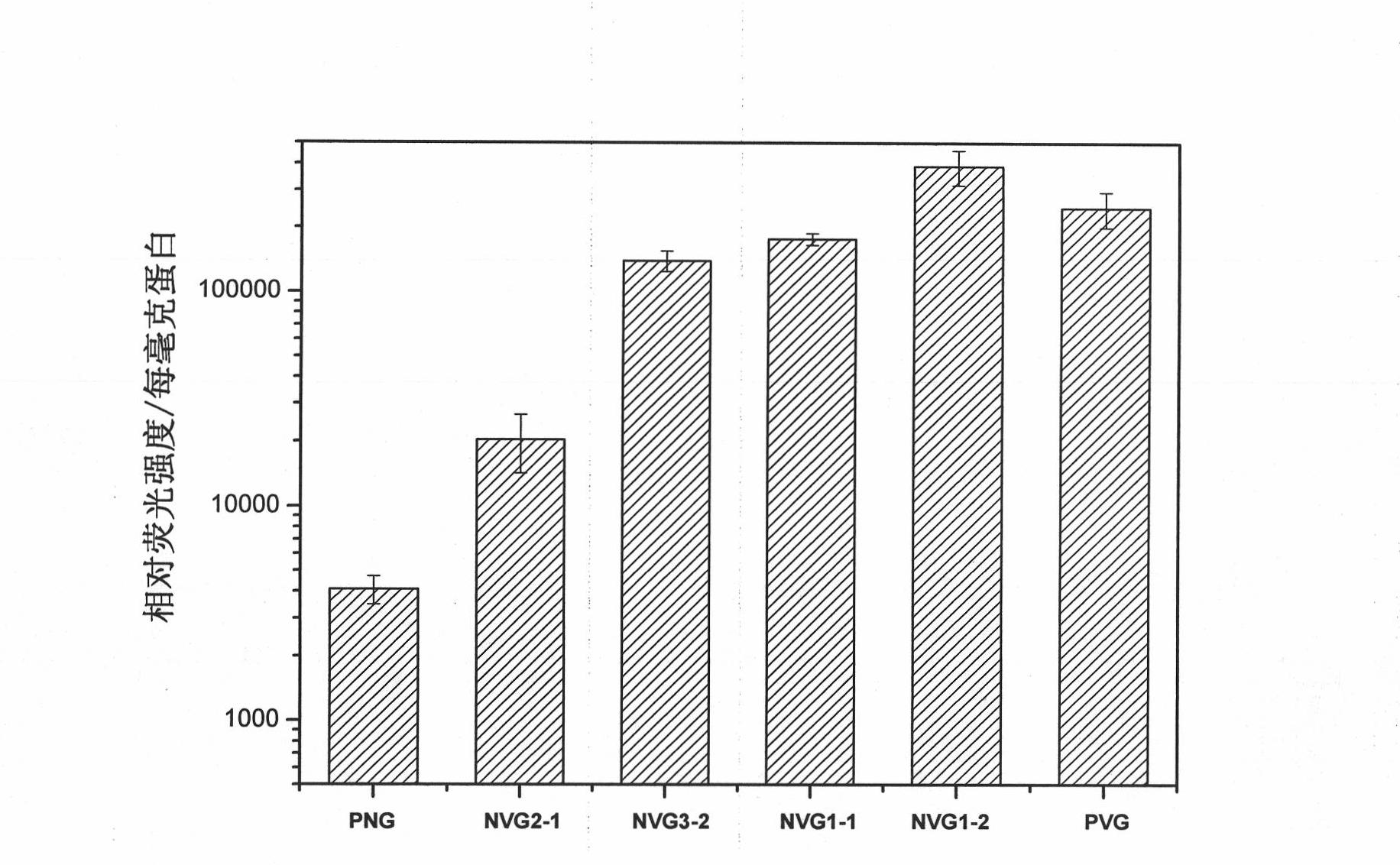

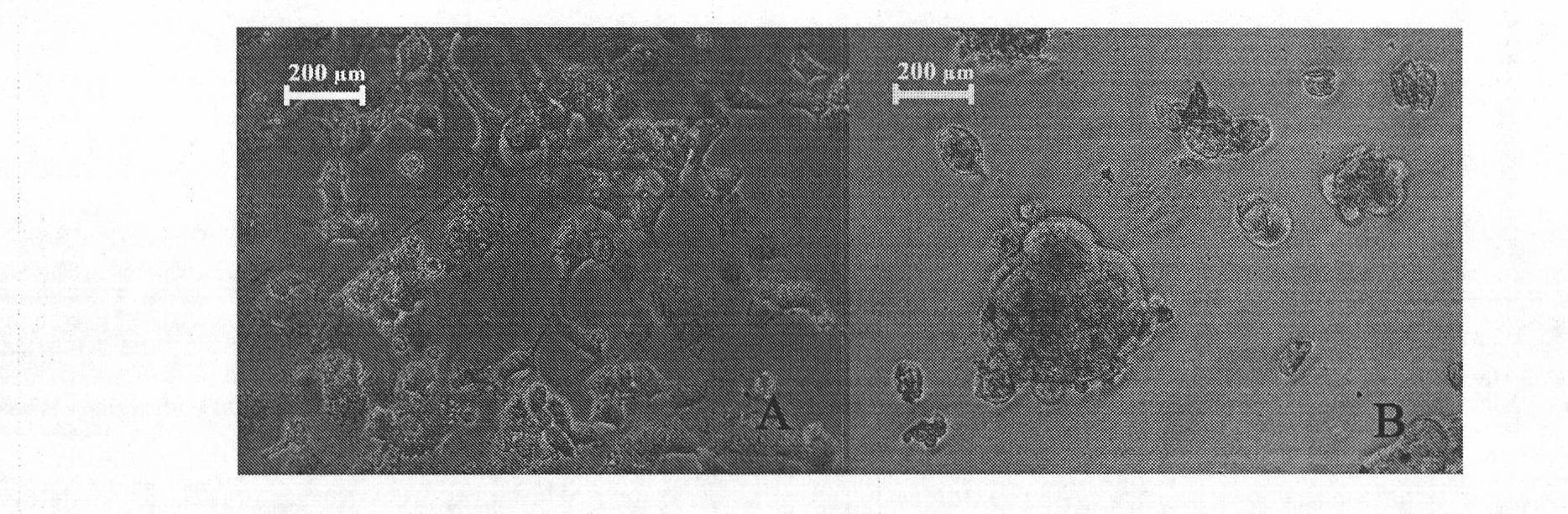

[0022] Gel sheets were prepared by the same procedure for mechanical properties, optical properties and cell tests. This gel sample was designated PNV2-1. The size of the sample for the tensile mechanical property test...

Embodiment 2

[0025] The monomer N-N-isopropylacrylamide (7.2mg), 2-vinyl-4,6-diamino-1,3,5-triazine (4.8mg) and the cross-linking agent polyethylene glycol diacrylate (8 mg) was added to a 1.5 ml centrifuge tube, and after dissolving the monomer and the cross-linking agent with 200 μl of DMSO, the photoinitiator Irgacure 2959 (0.4 mg) was added. A solvent containing monomers, crosslinking agents and initiators was injected into a closed mold, and the mold was irradiated in a UV curing box for 20 minutes to initiate free radical polymerization. Then the mold was opened to take out the gel, rinsed several times with deionized water, soaked for 7 days, and replaced the deionized water every 12 hours.

[0026] Gel sheets were prepared by the same procedure for mechanical properties, optical properties and cell tests. This gel sample was named PNV3-2. The size of the sample for the tensile mechanical property test is 20mm×2mm, and the thickness is 500μm. The sample size of the compression me...

Embodiment 3

[0029] Monomer N-isopropylacrylamide (6mg), 2-vinyl-4,6-diamino-1,3,5-triazine (6mg) and cross-linking agent polyethylene glycol diacrylate (8mg ) into a 1.5ml centrifuge tube, and after dissolving the monomer and the cross-linking agent with 200 μl of DMSO, the photoinitiator Irgacure 2959 (0.4 mg) was added. A solvent containing monomers, crosslinking agents and initiators was injected into a closed mold, and the mold was irradiated in a UV curing box for 20 minutes to initiate free radical polymerization. Then the mold was opened to take out the gel, rinsed several times with deionized water, soaked for 7 days, and replaced the deionized water every 12 hours.

[0030] Gel sheets were prepared by the same procedure for mechanical properties, optical properties and cell tests. This gel sample was designated PNV1-1. The size of the sample for the tensile mechanical property test is 20mm×2mm, and the thickness is 500μm. The sample size of the compression mechanical property ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com