Cyclic amine sulfur dioxide gas absorbent and preparation method thereof

A gas absorbent and absorbent technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of unfavorable industrialization and high cost of amino acid ionic liquids, achieve low operating costs, improve desulfurization effect, and reduce SO2 The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

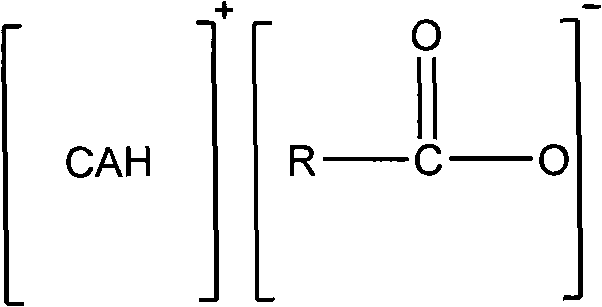

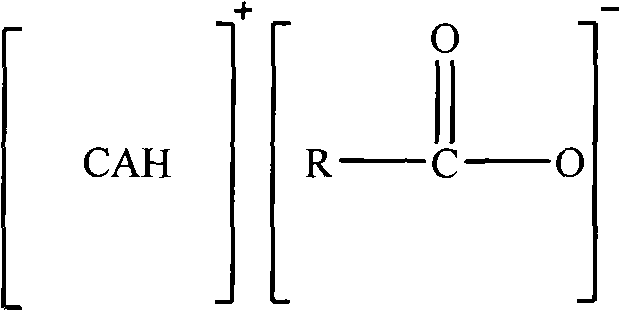

Method used

Image

Examples

Embodiment 1

[0022] The three-necked flask, condensing reflux tube, capped dropping funnel and stirring device are assembled together. The molar ratio of hexamethylenetetramine to formic acid is 1:4, and ethanol is used as the solvent. The temperature was controlled at 50°C, the formic acid solution was added dropwise, and the reaction was carried out for 10 hours. The solvent and excess raw materials were removed by rotating the mixed liquid under reduced pressure at 60°C, and the obtained liquid was put into a vacuum drying oven at 50°C for 36 hours, and finally a colorless ionic liquid of hexamethylenetetramine was obtained. Place the absorbent in a vacuum drying oven at 50°C for later use.

[0023] Accurately weigh the hexamethylenetetramine ionic liquid and place it in the absorber. The absorber is placed in a constant temperature system at 10°C, and SO is introduced into the absorber. 2 The gas, the absorbent becomes a viscous liquid, the absorption equilibrium can be reached within 2 ho...

Embodiment 2

[0027] The three-necked flask, condensing reflux tube, capped dropping funnel and stirring device are assembled together. The molar ratio of hexamethylenetetramine to acetic acid is 1:4, and ethanol is used as the solvent. The temperature was controlled at 90°C, acetic acid solution was added dropwise, and the reaction was carried out for 2 hours. The mixed liquid was subjected to reduced-pressure rotary distillation at 70°C to remove the solvent and excess raw materials, and the obtained liquid was put into a vacuum drying oven at 50°C for 36 hours, and finally the hexamethylenetetramine acetic acid ionic liquid was obtained. Place the absorbent in a vacuum drying oven at 50°C for later use.

[0028] Accurately weigh the hexamethylenetetramine acetic acid ionic liquid and place it in the absorber. The absorber is placed in a constant temperature system at 25°C, and SO is introduced into the absorber. 2 Gas, the absorption equilibrium can be reached within 1.5 hours.

[0029] Plac...

Embodiment 3

[0031] According to the molar ratio of imidazole to formic acid of 1:2, put it in a polytetrafluoroethylene liner, then put it in an autoclave, and react at 120°C for 10 hours. The obtained mixture was then placed in a vacuum drying oven at 100°C for 24 hours, and finally a colorless ionic liquid of imidazole carboxylic acid was obtained. Place the absorbent in a vacuum drying oven at 50°C for later use.

[0032] Accurately weigh the imidazole formic acid ionic liquid and place it in the absorber. The absorber is placed in a constant temperature system at 30°C, and SO is introduced into the absorber. 2 Gas, the absorbent turns into a yellow transparent liquid, and the absorption equilibrium can be reached within 2 hours.

[0033] Place the ionic liquid with absorption equilibrium in an environment of 100℃ for SO 2 Desorption test, absorption of SO 2 The mole fraction of is 0.6847, and the desorption rate in 1 hour is 94.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com