Tackifying anti-calcium salt polymer filtrate reducer and preparation method

A technology of fluid loss reducer and polymer, which is applied in the field of drilling fluid to achieve the effect of low permeability and good rubber protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

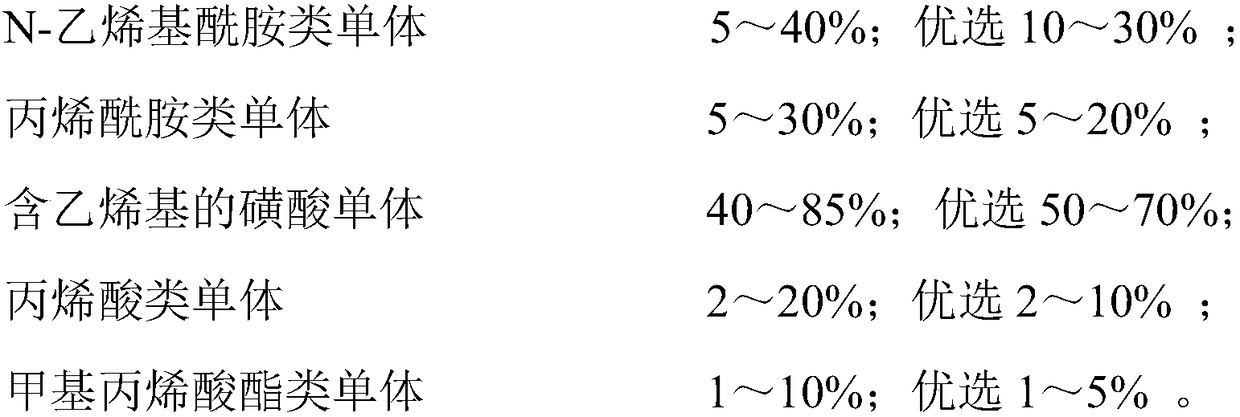

Method used

Image

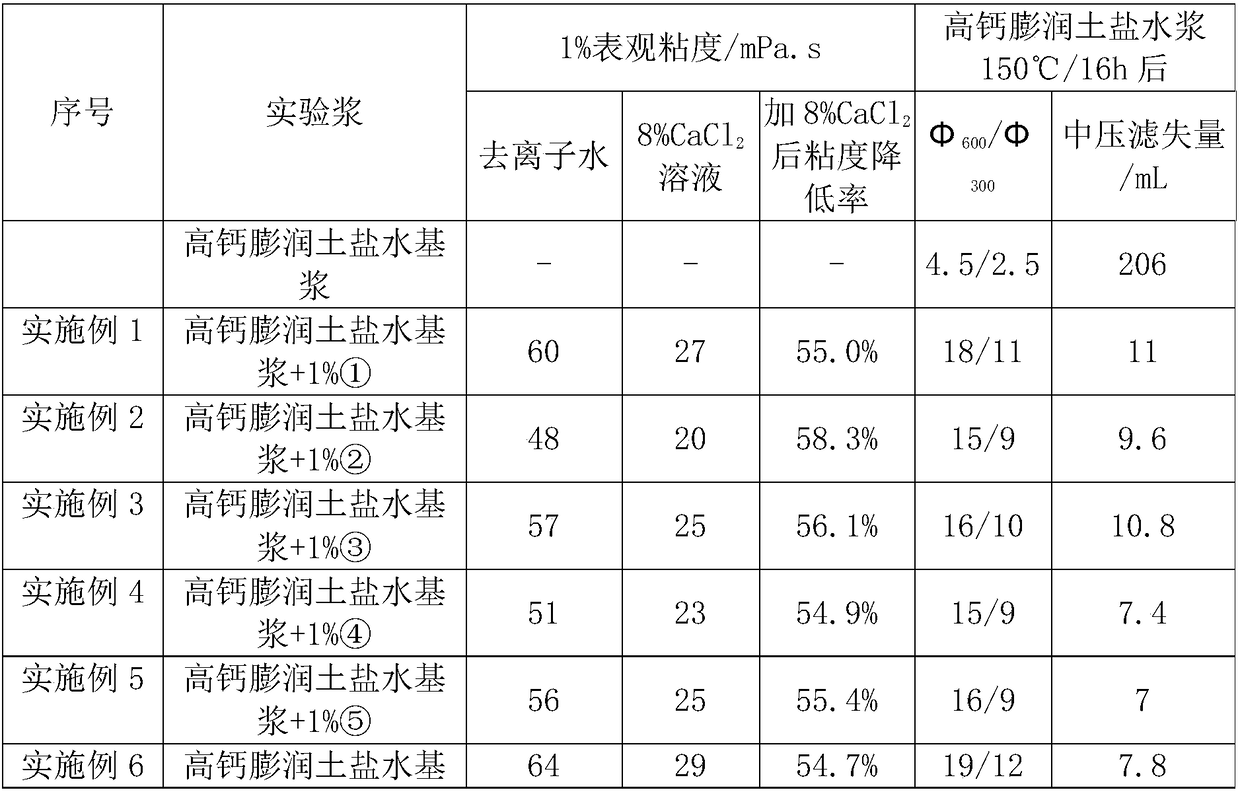

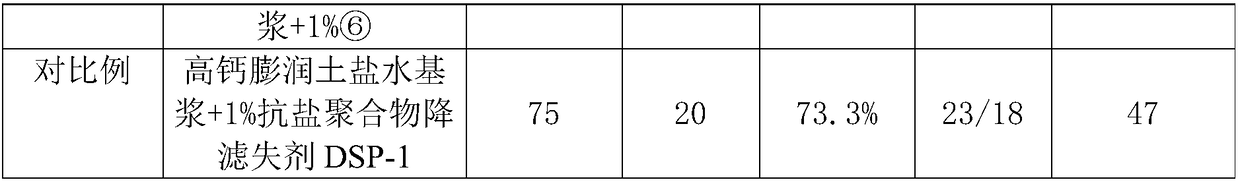

Examples

Embodiment 1

[0053](1) Add 10g N-vinylformamide, 6g acrylamide, 80g 2-acrylamido-2-methylpropanesulfonic acid, 2.5g acrylic acid, 1.5g methyl methacrylate into 150g deionized water, and use 40g 40% sodium hydroxide solution adjusts the pH value at 8 to obtain mixed solution A, and the total concentration of monomers in mixed solution A is 34.5%

[0054] (2) Add 0.3g xanthan gum in mixed solution A, pass N 2 After 0.5 hour, mixed solution B was obtained, wherein xanthan gum was 0.1% by weight of mixed solution B.

[0055] (3) Add 0.05 g of initiator ammonium persulfate and sodium bisulfite and 0.3 g of complexing agent disodium edetate to mixed solution B at 50° C., and react for 3 hours to obtain a gel-like product, wherein The initiator dose is 0.1% of the total weight of the monomer; disodium edetate is 0.1% of the weight of the mixed solution B;

[0056] (4) Shear and granulate the gel-like product, dry it at 85°C for 10 hours, and pulverize it to obtain the viscosity-increasing anti...

Embodiment 2

[0059] (1) Add 20g of N-vinylformamide, 5g of acrylamide, 70g of 2-acrylamido-2-methylpropanesulfonic acid, 3g of acrylic acid, and 2g of methyl methacrylate into 100g of deionized water, and use 38g of 40% Sodium hydroxide solution adjusts the pH value at 8 to obtain mixed solution A, and the total concentration of monomers in mixed solution A is about 42%.

[0060] (2) Add 4g polyanionic cellulose (HV-PAC) in mixed solution A, logical N 1 hour, obtain mixed solution B, wherein polyanionic cellulose (HV-PAC) is 1.68% of mixed solution B weight.

[0061] (3) Add 0.05 g of initiator ammonium persulfate and sodium bisulfite and 0.3 g of complexing agent disodium edetate to mixed solution B at 30° C., and react for 5 hours to obtain a gel-like product, wherein The initiator dose is 0.1% of the total weight of the monomers; disodium edetate is 0.13% of the weight of the mixed solution B;

[0062] (4) Shear and granulate the gel-like product, dry it at 90°C for 8 hours, and pulver...

Embodiment 3

[0065] (1) Add 10g of N-vinylformamide, 10g of acrylamide, 77g of 2-acrylamido-2-methylpropanesulfonic acid, 2g of acrylic acid, and 1g of methyl methacrylate into 200g of deionized water, and use 40g of 40% The sodium hydroxide solution adjusted the pH value at 7 to obtain a mixed solution A, and the total concentration of the monomers in the mixed solution A was 29%.

[0066] (2) Add 5g of β-cyclodextrin to the mixed solution A, and pass N2 under stirring for 1.5 hours until the β-cyclodextrin is completely dissolved to obtain a mixed solution B, wherein the β-cyclodextrin is 1.89% of the weight of the mixed solution B .

[0067] (3) Add 0.05 g of initiator ammonium persulfate and sodium bisulfite and 0.5 g of complexing agent disodium edetate to mixed solution B at 60° C., and react for 7 hours to obtain a gel-like product, wherein The amount of initiator is 0.1% of the total weight of the monomer; disodium edetate is 0.15% of the weight of the mixed solution B;

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com