Manufacture method and applications of high temperature resistant and deformation resistant composite microporous membrane

A technology of microporous membranes and polymers, which is applied in the direction of electrical components, circuits, battery pack components, etc., and can solve problems such as diaphragm corrosion, poor environmental friendliness, and pore structure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

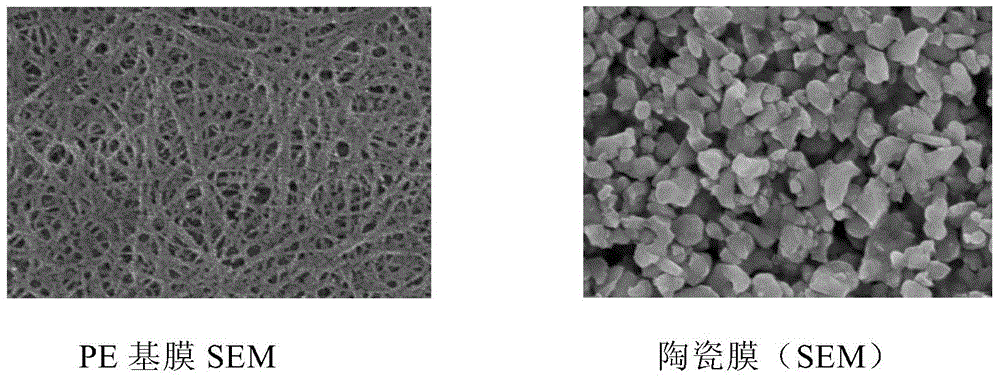

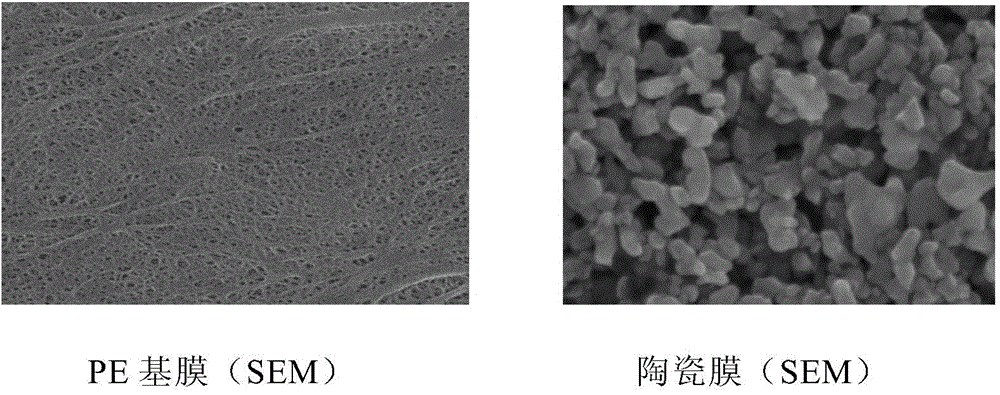

Image

Examples

preparation example Construction

[0021] The preparation method of the high temperature resistant and deformation resistant composite microporous film of the present invention comprises the following steps:

[0022] (a) providing a polymeric microporous membrane;

[0023] The polymer microporous membrane (also known as polymer microporous membrane) of the present invention is a material that is difficult to absorb and swell due to the limitation of the electrolyte, and is selected from at least one of the following polymers: ultra-high molecular weight polyethylene, linear Polyethylene, branched polyethylene, high density polyethylene, low density polyethylene, polypropylene, polyvinyl alcohol, polyvinyl acetate, polytetrafluoroethylene, polyvinylidene fluoride, polyethylene terephthalate, Polyurethane, polyimide, polyacrylonitrile, polymethyl methacrylate, polybutyl acrylate, polystyrene and its copolymers, polyvinyl chloride, polyimide, polyaramid, nylon, polysulfone, poly Carbonate, polyacrylamide, polymet...

Embodiment

[0087] Below in conjunction with embodiment, the present invention is further described.

[0088] experiment method

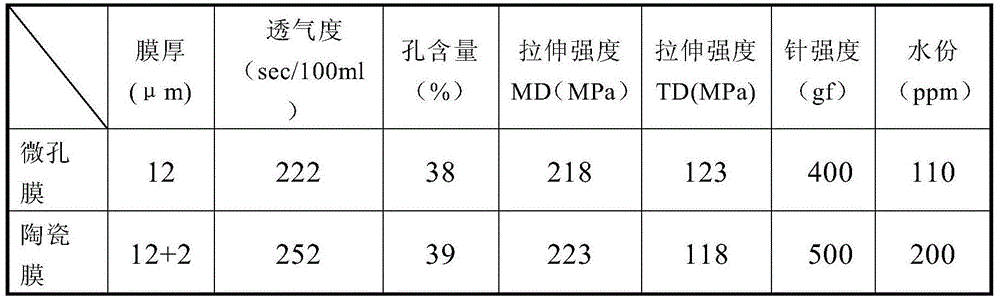

[0089] 1. Thickness

[0090] Measured with a Marr Film Thickness Gauge

[0091] 2. Air permeability

[0092] Measured with Gurley Air Permeability Tester 4110

[0093] 3. Pore content

[0094] Determination by Quanta Poremaster-33 automatic mercury porosimeter

[0095] 4. Heat shrink

[0096] At room temperature and constant temperature, the original length L0 of the sample along the direction of machine travel was measured, and it was perpendicular to the direction of travel of the machine T0. The sample was heated in a constant temperature and humidity controllable oven at 105 °C for 1 h and then cooled to the original test conditions. Measure the length L1 along the machine travel direction and the length T1 perpendicular to the machine travel direction of the sample at this time, and the calculation formula is as follows:

[0097] MD%=(L1-L0) / L0×10...

Embodiment 1

[0108] 1. Preparation of Polymer Porous Membranes

[0109] To the molecular weight of 2 × 10 -6 Add to g / mol polyethylene, based on the weight of the polyethylene, 0.3% antioxidant 2,6-tert-butyl-4-methylphenol and phosphite (the weight ratio of the two is 1:1), after mixing It is added to the screw extruder, and the side material port of the extruder supplies natural mineral oil as a solvent, and the added amount of the solvent accounts for 65% of the total weight of polyethylene.

[0110] Kneading at 210°C, stirring and shearing in the screw conveying section at a speed of 75 rpm to form polyethylene gel, extruding a stretched film of 745 μm from the T-die at the top of the extruder, and biaxially stretching stretched (longitudinal stretch ratio of 5, transverse stretch ratio of 7.8), after degreasing, heat-setting at 125 ° C to obtain 12 μm ultra-high molecular weight polyethylene microporous membrane.

[0111] 2. Preparation of Ceramic Slurry

[0112] Weigh main binder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com