Antibacterial textile and preparation method thereof

A technology for antibacterial textiles and textiles, applied in textiles and papermaking, biochemical fiber treatment, fiber treatment and other directions, can solve the problems of failing to have the expected fastness effect, limited and other problems, and achieve the effect of simple and easy method and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

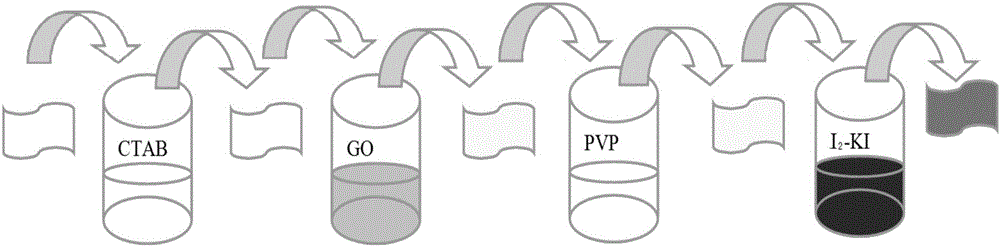

[0029] Embodiment 1: the preparation method of antibacterial cotton fabric, flow chart is as figure 1 shown, including the following steps:

[0030] (1) Weigh the graphene oxide prepared above and ultrasonically treat it in water for about 30 minutes to obtain a GO aqueous solution with a concentration of 5 g / L. Before use, clean the solution in an ultrasonic cleaner for 30 minutes at a power of 300w.

[0031] (2) Cut the cotton fabric (10cm*5cm in size) and immerse it in 3g / L CTAB solution for modification treatment for about 1 hour. The temperature of the treatment process is 85°C. Yes, cationically modified cotton fabrics are obtained.

[0032] (3) After drying, the cationic surface-modified cotton fabric was directly immersed in 5g / L GO aqueous solution at room temperature for 20min, then dried at 60°C for 10min, and then immersed in 3% PVP aqueous solution for 20min. Afterwards, the sample was taken out and placed in an oven at 60°C for 10 minutes to dry to obtain a cot...

Embodiment 2

[0035] The steps of this embodiment are the same as those of Example 1, the difference being that the concentration of the GO aqueous solution is 2g / L in the step (1); The phenomenon shows that the concentration of GO aqueous solution has less influence on the finishing effect than that of iodine concentration.

Embodiment 3

[0037] The steps of this embodiment are the same as those of Example 1, the difference being that: in step (1), the 5g / L GO aqueous solution was cleaned for 30min under the condition of 600w power; Treat at 80°C for 30min; in step (3), soak in the PVP aqueous solution with a mass fraction of 5% for 20min; Potassium iodide solution for 10min to remove uncomplexed iodine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com