Polymers and methods to mitigate the loss of silicone deposition from keratinous substrates

A technology of polysiloxanes, compositions, applied in the field of stain removal conditioning compositions in personal care cleansing applications, which can solve the problem of diminished conditioning benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0335] The nonionic amphiphilic polymer component of the present invention is prepared using free radical initiated dispersion polymerization. The polymerization reactor consisted of a water-cooled resin kettle equipped with a reflux condenser, a nitrogen purge line, a mechanical stirrer, and a thermocouple connected to a temperature control assembly. The mixture of monomers, crosslinkers and processing aids described in Table 1 was added to the resin kettle, followed by the polymerization solvent. The amounts of these components in % by weight are shown in the table for each polymer preparation. While heating the reaction medium to the target polymerization temperature, the reactor is purged with nitrogen for at least half an hour. When the reaction temperature reaches the set polymerization temperature, usually about 67°C, inject the initiator solution 2,2'-azobis(2-methylbutyronitrile) (0.12% by weight based on the dry weight of the polymer) into the reaction pot to start...

Embodiment 11-24

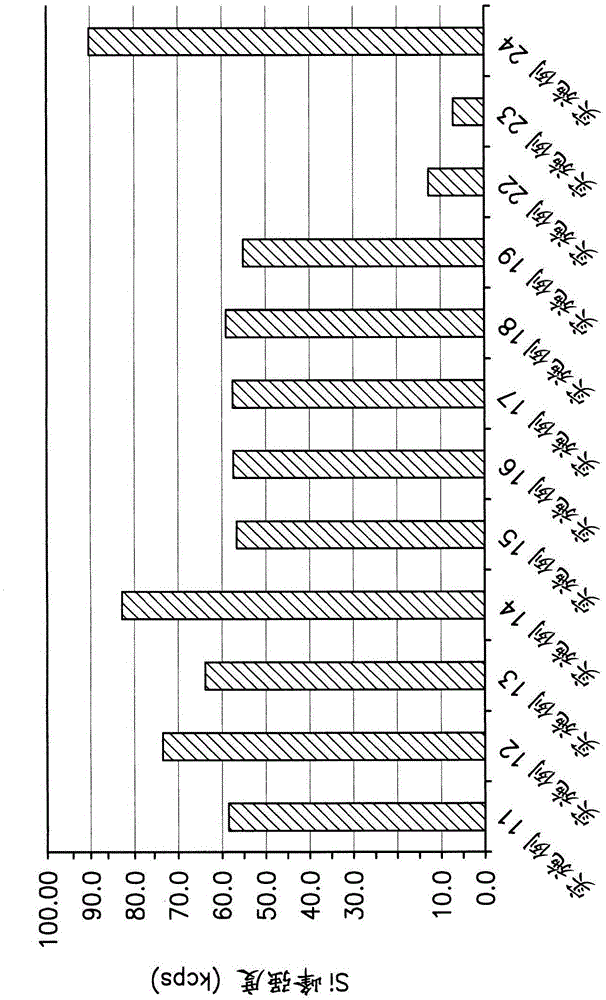

[0342] A 2-in-1 hair conditioner shampoo containing the nonionic amphiphilic polymer prepared according to Examples 1-10 was formulated using the ingredients described in Table 2.

[0343] Table 2

[0344]

[0345] Shampoo compositions are prepared according to the following procedure:

[0346] Part A:

[0347] 1) Disperse the polymer evenly in D.I. water;

[0348] 2) Add anionic and amphoteric surfactants and mix for 15 minutes.

[0349] Part B:

[0350] 3) A 2 wt. % (wt. / wt.) dispersion of cationic guar gum in D.I. water was prepared and mixed with the Part A component.

[0351] Part C:

[0352] 4) Add part C component to part AB component mixture and mix until uniform;

[0353] 4) Adjust the ABC component mixture to a pH of about 6 with NaOH.

[0354] The same 2-in-1 comparative shampoo compositions were prepared similarly except one was formulated with a commercially available thickener polymer (INCI name: Acrylate Copolymer) and the control shampoo formula...

Embodiment 25

[0363] Poly(1-vinylpyrrolidone-co-vinyl acetate) linear copolymer (62.7 wt% NVP) obtained from Sigma-Aldrich (CAS No. residues, 37.3 wt% VA residues) formulated into a 2-in-1 shampoo composition except that 1.5 wt% linear copolymer (100% actives), 15 wt% Sulfochem TM ES-2 CWK Anionic Surfactant and 2 wt% Chembetaine TM C Amphoteric Surfactant (all weights are based on the total weight of the formulated composition). The amount of silicon (silicon atoms) deposited on wool cloth swatches treated with the 2-in-1 shampoo composition was measured by X-ray fluorescence (XRF) spectroscopy according to the experimental method described above. The yield stress (24 hours after formulation) of the shampoo composition was also measured as described in the above method.

[0364] The measured silicon peak intensity was 71.8 kcps and the yield stress of the shampoo formulation was 0 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com