Enzyme-GO-MOFs nano composite catalyst and preparation method thereof

A nanocomposite and catalyst technology, which is applied in the field of enzyme-GO-MOFs nanocomposite catalyst and its preparation, can solve the problems of increasing hydrophilicity and solution dispersibility, poor dispersibility, application limitations, etc., and achieves a simple and easy preparation method. , the effect of high porosity and increased catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

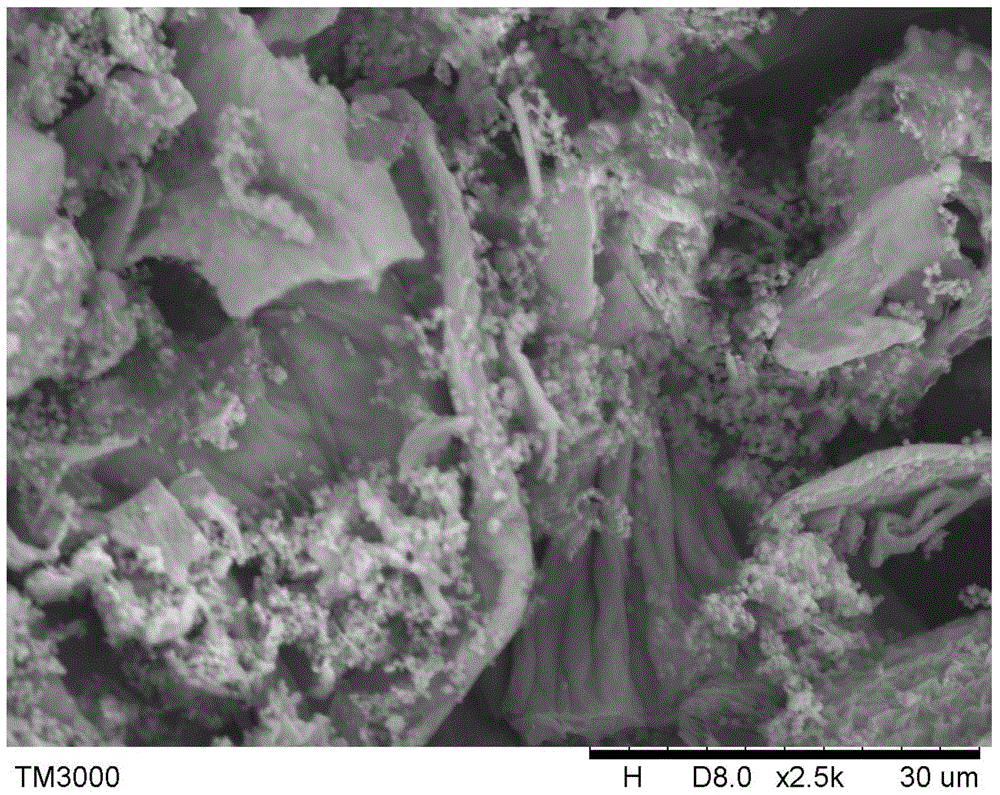

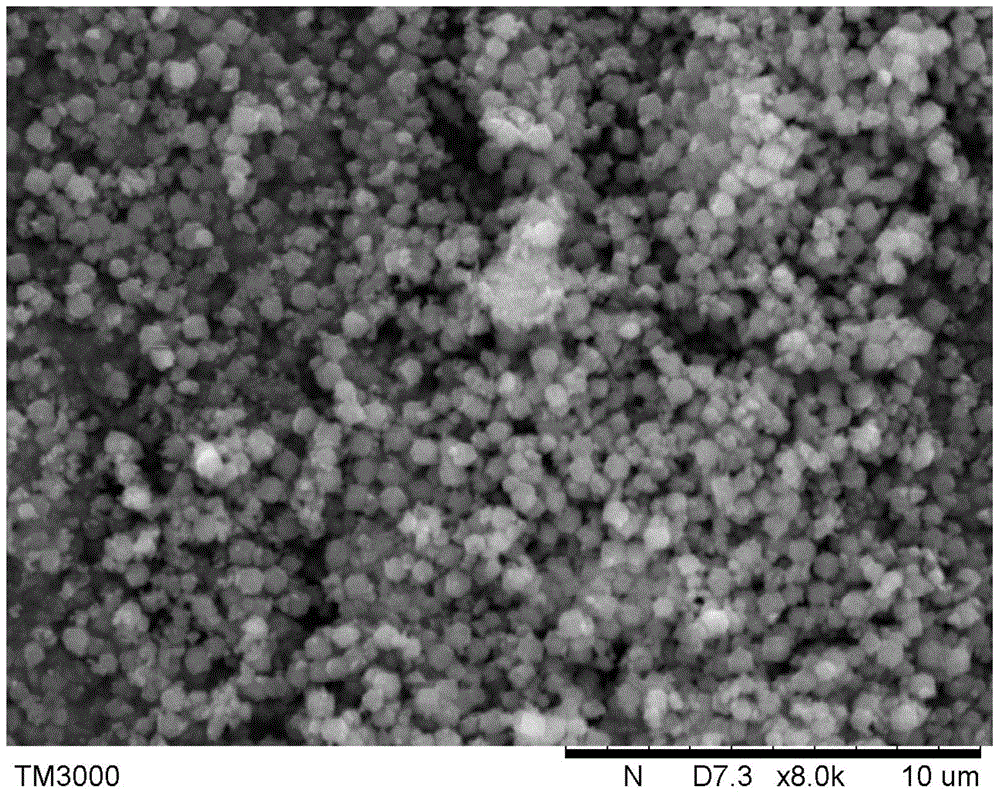

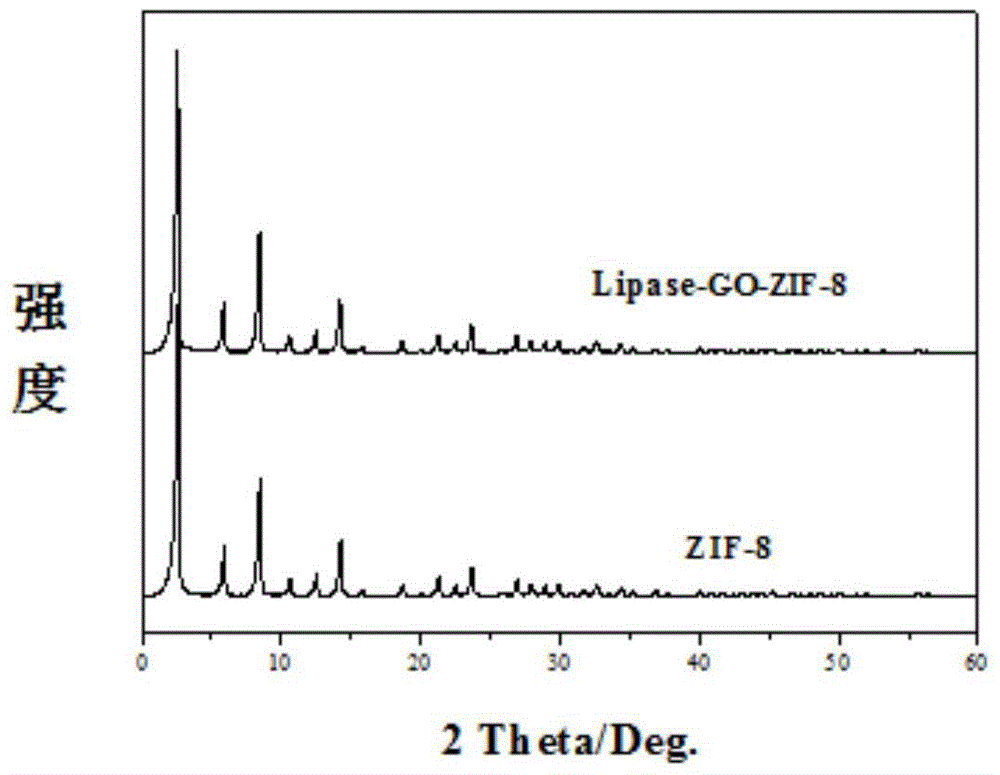

[0038] Example 1: Prepare GO-MOFs nanocomposite coated lipase according to the following steps:

[0039] (1) Take 20 mg of lipase, make (20 mg-mL) enzyme solution with 1 mL deionized water, then add 20 mg polyvinylpyrrolidone (PVP) (20 mg-mL) to obtain PVP modified enzyme solution.

[0040] (2) Take zinc nitrate hexahydrate and 2-methylimidazole to make a solution (20mM, 15mL) with methanol respectively, take 1mg of GO and add it to the methanol solution of zinc nitrate hexahydrate, after ultrasonic treatment for 6h, add 2-methylimidazole The methanol solution of imidazole was degassed in an ultrasonic bath for 5 min to obtain the synthetic stock solution of GO-MOFs composites.

[0041] (3) Mix the modified enzyme solution obtained in the above steps with the GO-MOFs composite synthetic stock solution, and then treat it in an ultrasonic bath for 1 min to obtain a uniformly mixed reaction solution.

[0042] (4) Stand for reaction at 50°C for 5h, then collect by centrifugation ...

Embodiment 2

[0048] Example 2: Prepare GO-MOFs nanocomposite coated cytochrome c according to the following steps:

[0049] (1) Take 50 mg of cytochrome c, mix it with 2 mL of deionized water to make (25 mg-mL) enzyme solution, and then add 20 mg of poly-N-vinylformamide (10 mg-mL) to obtain a modified enzyme solution.

[0050] (2) Take zinc nitrate hexahydrate and methanol to make (20mM, 30mL) solution, imidazole and methanol to make (150mM, 25mL) solution, take 48.6mg of GO and add zinc nitrate hexahydrate methanol solution, ultrasonic bath treatment After 8 h, a methanol solution of imidazole was added and degassed in an ultrasonic bath for 10 min to obtain a synthetic stock solution of GO-MOFs composites.

[0051] (3) Mix the modified enzyme solution obtained in the above steps with the GO-MOFs composite synthesis stock solution, and then treat it in an ultrasonic bath for 5 minutes to obtain a uniformly mixed reaction solution.

[0052] (4) Stand for reaction at 25°C for 12 hours, then...

Embodiment 3

[0057] Example 3: Prepare GO-MOFs nanocomposite coated with horseradish peroxidase according to the following steps:

[0058] (1) 90 mg of horseradish peroxidase was mixed with 3 mL of deionized water to make (30 mg-mL) enzyme solution, and then 30 mg of Pluronic F-127 (10 mg-mL) was added to obtain a modified enzyme solution.

[0059] (2) Prepare cobalt chloride hexahydrate with N,N-dimethylformamide (25mM, 54mL), and 2-carboxybenzimidazole with N,N-dimethylformamide (100mM, 18mL) For the solution, take GO90mg and add it to the N,N-dimethylformamide solution of cobalt chloride hexahydrate. After ultrasonic bath treatment for 10h, add the N,N-dimethylformamide solution of 2-carboxybenzimidazole The bath was degassed for 20 min to obtain the synthetic stock solution of GO-MOFs composites.

[0060] (3) Mix the modified enzyme solution obtained in the above steps with the GO-MOFs nanocomposite synthesis stock solution, and then treat it in an ultrasonic bath for 8 minutes to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com