Aqueous polishing composition and process for chemically mechanically polishing substrates for electrical, mechanical and optical devices

A technology for water polishing and composition, applied in the field of new aqueous polishing composition, to achieve the effect of excellent global and local flatness, improved process management, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

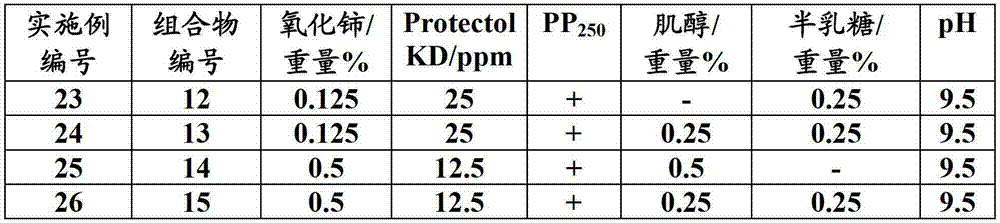

Examples

preparation example Construction

[0145] The compositions of the present invention can be prepared without any particularity, but by dissolving or dispersing the abovementioned ingredients (A), (B) and (C) and optionally (D) and / or (E) in an aqueous medium, in particular performed in deionized water. For this purpose, customary and standard mixing methods and mixing equipment can be used, such as stirred tanks, in-line dissolvers, high-shear high-speed mixers, ultrasonic mixers, homogenizer nozzles or convective mixers. The composition of the invention thus obtained is preferably filterable through a filter having suitable mesh openings to remove coarse-grained particles such as agglomerates or aggregates of finely divided solid abrasive particles (A).

[0146] The compositions of the invention are well suited for the methods of the invention.

[0147] In the method of the invention, the substrate of an electronic, mechanical and optical device, especially an electronic device, most preferably an integrated c...

Embodiment 1-11

[0166] Preparation of Aqueous Polishing Compositions 1-11

[0167] To prepare aqueous polishing compositions 1-11, cerium oxide (average particle size d as measured by dynamic laser light scattering) 50 120-140nm), sodium hexametaphosphate (PP; weight ratio of cerium oxide to PP = 200, hereinafter referred to as PP 200 ; The weight ratio of cerium oxide to PP=300, hereinafter referred to as PP 300 ) and inositol dispersed or dissolved in ultrapure water. The amounts used are summarized in Table 2.

[0168] Table 2: Composition of Aqueous Polishing Compositions 1-11

[0169] Composition number

[0170]Aqueous polishing compositions 1-11 of Examples 1-11 are extremely useful for chemical mechanical polishing of substrates for electronic, mechanical and optical devices.

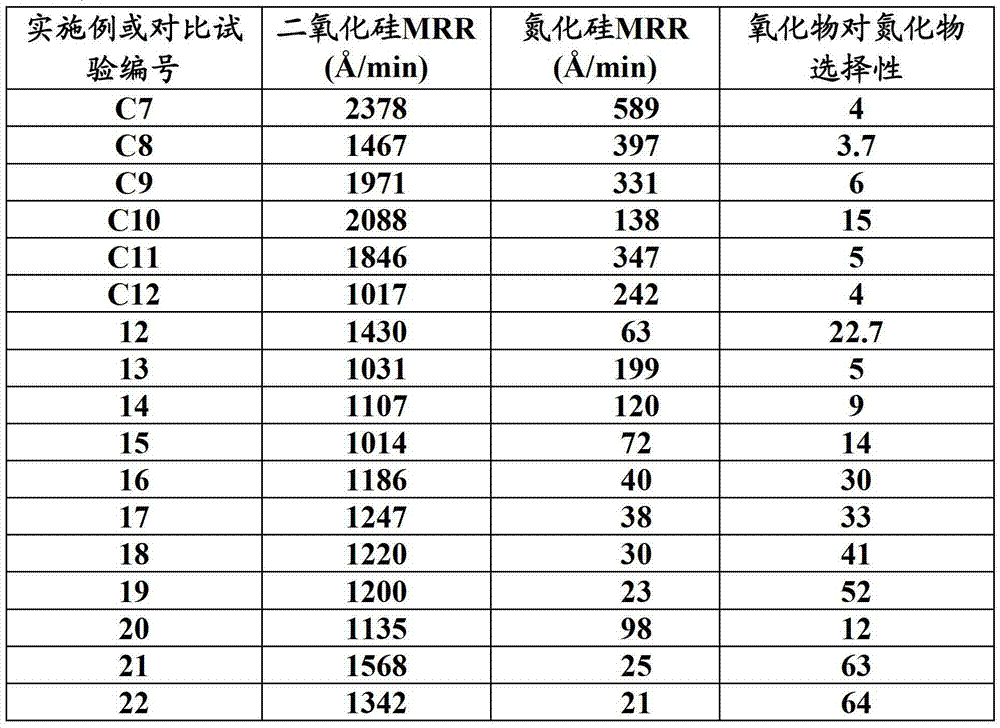

Embodiment 12-22 and comparative example C7-C12

[0172] CMP and oxide-to-nitride selectivity of silica-coated blank wafers and silicon nitride-coated blank wafers

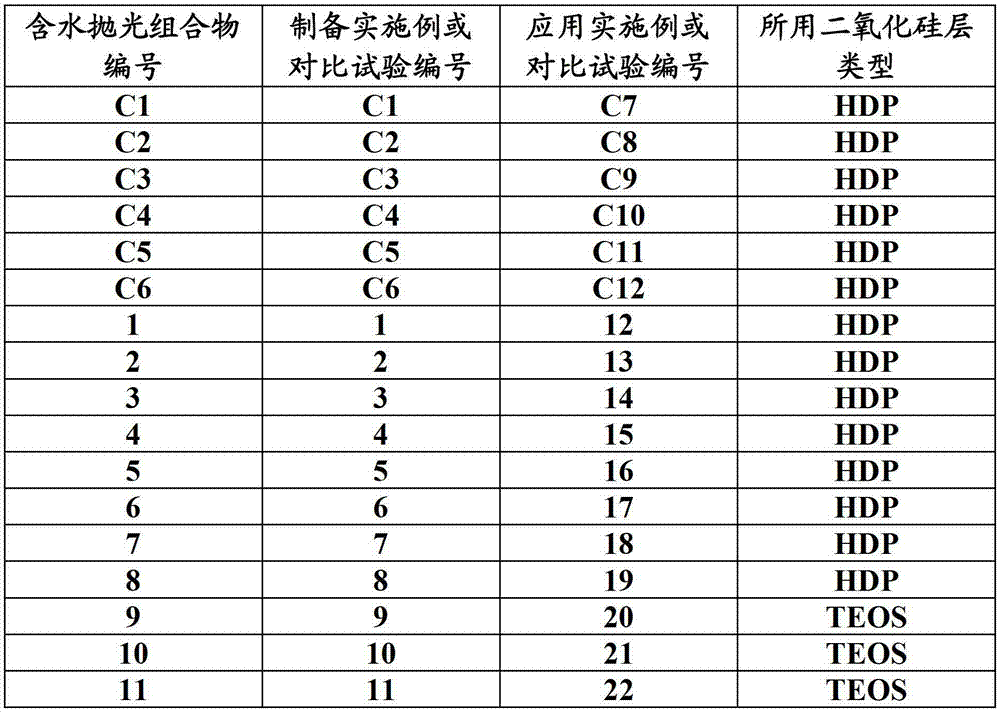

[0173] Table 3 shows the aqueous polishing compositions used in Examples 12-22 and Comparative Tests C7-C12.

[0174] Table 3: Aqueous polishing compositions and silica layer types used in Examples 12-22 and Comparative Tests C7-C12

[0175]

[0176] HDP: high density plasma silicon dioxide;

[0177] TEOS: Tetraethyl orthosilicate CVD type oxide

[0178] In the following, CMP uses the following process parameters.

[0179] Embodiment 12 and comparative tests C7-C10:

[0180] - Polishing equipment: Strasbaugh6EGnHance (rotary type):

[0181] - Platform speed: 93rpm;

[0182] - Carrier speed: 87rpm;

[0183] - IC1000 / Suba400K groove polishing pad produced by Rohm&Haas;

[0184] - Use the S603M diamond regulator to adjust in situ;

[0185] - Slurry flow rate: 200ml / min;

[0186] - Substrates: SiO2 blank wafers (see Table 3) and 500nm CVD silicon nitride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com