Method for preparing water soluble vinyl-sulfone polyurethane class high molecular reactive dye with diazo coupling method

A polyurethane and vinyl sulfone type technology, applied in the field of polymer dyes, can solve the problems of high pollution, high cost, and poor affinity for polar fibers, etc., and achieve improved heat resistance, strong tinting power, and bright colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

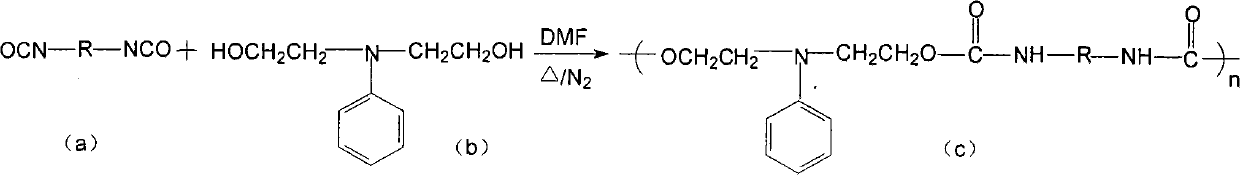

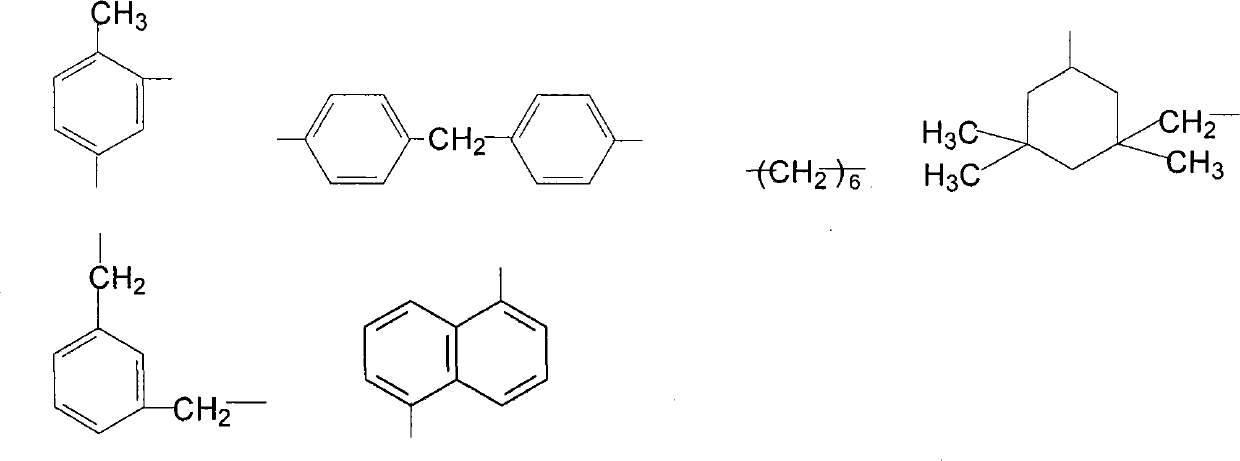

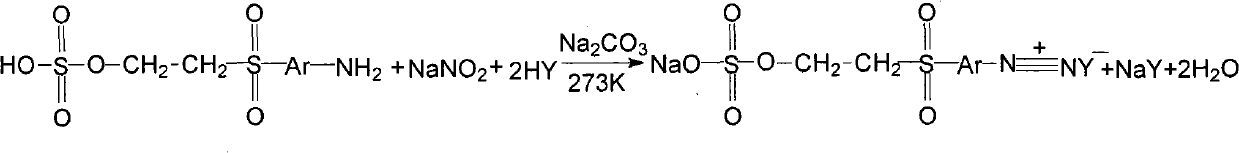

Method used

Image

Examples

Embodiment 1

[0036] Take 9.05 grams (0.05mol) of N-phenyldiethanolamine, add 150mL of DMF, magnetically stir to dissolve, add dropwise 8.807 grams (0.05mol) of toluene-2,4-diisocyanate (TDI) and a small amount of dibutyltin, Under protection, the temperature was raised to 85°C for 12 hours. After precipitation, filtration, washing and drying, a white polyurethane precursor solid was obtained.

[0037] Take 1.65mL of concentrated sulfuric acid, add it to 10mL of water, mix well, and wait until the temperature drops to 0°C for later use. Take 3.51 grams (0.012mol) of p-aminoazobenzene-β hydroxyethylsulfone sulfate (para-ester) and add it to 30mL of water, then add 10% sodium carbonate solution, adjust the pH of the system to 6-7, and stir until the para-position After the ester is completely dissolved, add 0.836 g of 99% (0.012 mol) sodium nitrite solid, stir until it is completely dissolved, and slowly add it dropwise into the above sulfuric acid solution, and stir until there is no free a...

Embodiment 2

[0040] The same polyurethane precursor as in Example 1 was used. Take 3.571 g (0.01 mol) of the same polyurethane precursor in Example 1, dissolve it completely with 100 mL of N,N'-dimethylformamide, and then lower the temperature of the solution to 0° C. with an ice-water bath.

[0041] Take 3mL of 36.5% concentrated hydrochloric acid, add it to 30mL of water, mix well, and wait until the temperature drops to 0°C for later use. Take 3.51 grams (0.012mol) of the para-ester and add it to 30mL of water, then add 10% sodium carbonate solution, adjust the pH of the system to 6-7, stir until the para-ester is completely dissolved, then add 0.836 grams of 99% (0.012mol) Sodium nitrate solid, stirred until completely dissolved, then slowly added dropwise to the above hydrochloric acid solution, and stirred until no free amine was present, which was the end point.

[0042] Slowly add the above-mentioned diazonium salt solution to the above-mentioned polyurethane precursor solution dr...

Embodiment 3

[0044] The same polyurethane precursor as in Example 1 was used. Take 3.571 g (0.01 mol) of the same polyurethane precursor in Example 1, dissolve it completely with 100 mL N, N'-dimethylformamide, and then lower the temperature of the solution to 0° C. with an ice-water bath.

[0045] Take 0.40mL of concentrated sulfuric acid, add it to 10mL of water, mix well, and wait until the temperature drops to 0°C for later use. Get 0.732 grams (2.5 mmol) of the para-ester and add it to 30 mL of water, then add 10% sodium carbonate solution, adjust the pH of the system to 6-7, stir until the para-ester is completely dissolved, then add 0.174 grams of 99% (2.5 mmol) Sodium nitrate solid, stirred until completely dissolved, then slowly added dropwise to the above sulfuric acid solution, stirred until no free amine was present, which was the end point.

[0046] Slowly add the above-mentioned diazonium salt solution to the above-mentioned polyurethane precursor solution dropwise, uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com