Active dye printing process

A technology of reactive dyes and printing technology, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of excessive ammonia nitrogen discharge, easy bleeding, poor color stability, etc., to reduce hydrolysis, reduce steaming time and efficiency, The effect of prolonged stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

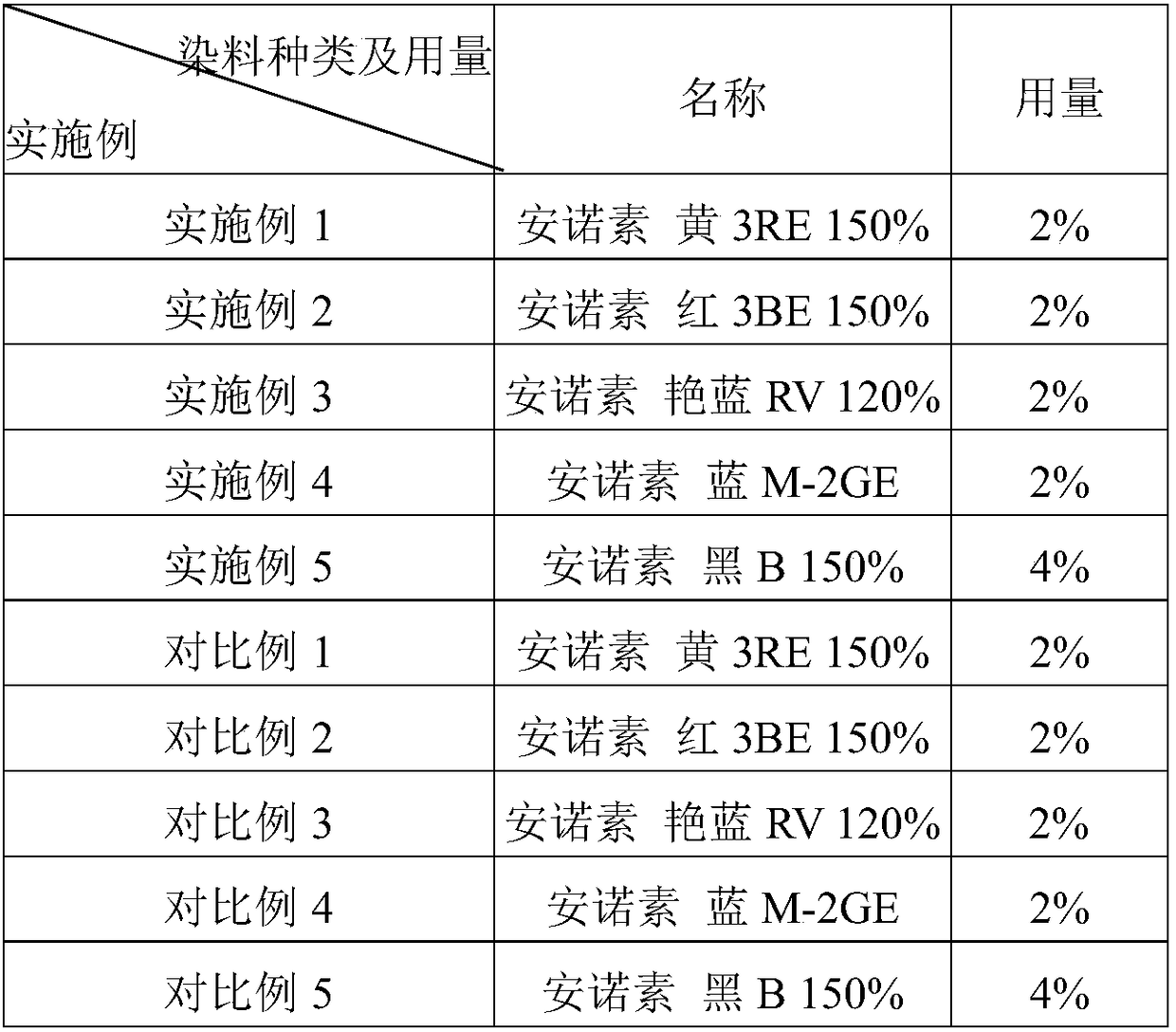

[0033] The reactive dye printing process in Examples 1 to 5 includes the following steps: the white gray cloth is printed successively, dried (100° C.), treated with alkali, steamed and fixed (temperature 130° C., time 45 s), and the first time Washing, soaping, and washing for the second time;

[0034] In the printing process, in the printing paste, the specific types and amounts of dyes in Examples 1 to 5 are shown in Table 1. In addition to the dyes, the following components are also included: the amount of anti-dyeing salt S is 1%, sodium alginate paste The dosage is 50% and the balance is water, and the above percentages are the mass percentages of each component relative to the total amount of printing paste. Printing pastes do not contain alkaline agents and / or urea.

[0035] In the soda rolling process, the composition of the color-fixing lye comprises the following components: the consumption of sodium carbonate is 10%, the consumption of sodium silicate is 8%, the c...

Embodiment 6

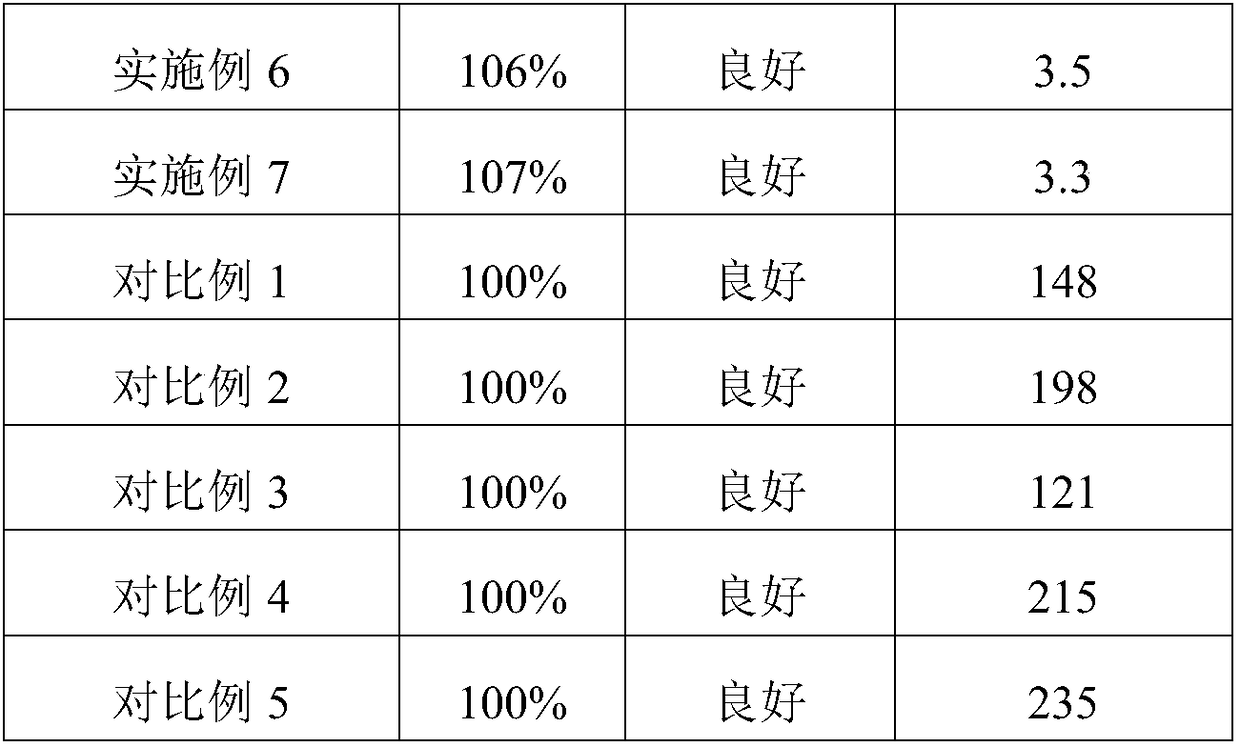

[0040] Except following parameter, the process parameter of embodiment 6 is all identical with embodiment 1.

[0041] The rolling liquid rate is 30%; during the alkali rolling process, the amount of sodium carbonate in the color-fixing lye used is 5%, the amount of sodium silicate is 10%, and the amount of sodium hydroxide is 2%; The dosage of reactive dye is 5%, the dosage of resist salt S is 1.5%, and the dosage of sodium alginate paste is 55%.

Embodiment 7

[0043] Except following parameter, the processing parameter of embodiment 7 is all identical with embodiment 1.

[0044] The liquid rolling rate is 50%; during the alkali rolling process, the amount of sodium carbonate used in the color-fixing lye is 15%, the amount of sodium silicate is 5%, and the amount of sodium hydroxide is 0.5%; the anti-staining salt in the printing paste The dosage of S is 0.5%, the dosage of sodium alginate paste is 45%; the drying temperature is 95°C; the condition of steaming and color fixing is: temperature 125°C, time 60s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com