Dyeing method for hybrid loose fibers

A dyeing method and loose fiber technology, which is applied in the dyeing field of mixed loose fibers, can solve problems such as large differences in optimal process conditions and great difficulty, and achieve the goals of shortening the processing flow, reducing energy and water consumption, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, wool / spun silk / modal mixed loose fiber with a mixing ratio of 70:12:18 is used for dyeing medium color.

[0021] Step 1: Reductive bleaching and oxidative bleaching pretreatment

[0022] The formula of reduction bleach treatment liquid is as follows: the concentration of sodium hydrosulfite is 3g / L, the concentration of sodium silicate is 1g / L, the treatment starts at room temperature, the temperature is raised to 85°C at 2°C / min for 40 minutes, and the reduction bleach is washed with water.

[0023] The formula of the oxidative bleaching solution is as follows: hydrogen peroxide 6g / L, sodium silicate 0.4g / L, sodium bicarbonate 0.7g / L, start treatment at room temperature, heat up to 80°C at 2°C / min, and treat for 50 minutes.

[0024] Step 2: Dyeing with reactive dyes

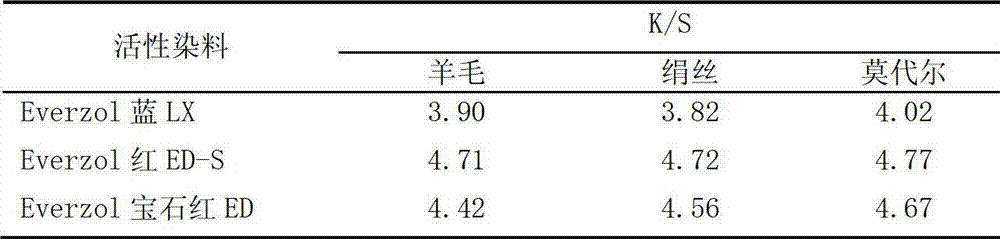

[0025] The pretreated wool / spun silk / modal mixed loose fiber is dyed with three reactive dyes: Everzol Blue LX, Everzol Red ED-S and Everzol Ruby Red ED.

[0026] The formula of the ...

Embodiment 2

[0031] In this embodiment, wool / spun silk / modal mixed loose fibers with a mixing ratio of 70:20:10 are dyed in light colors.

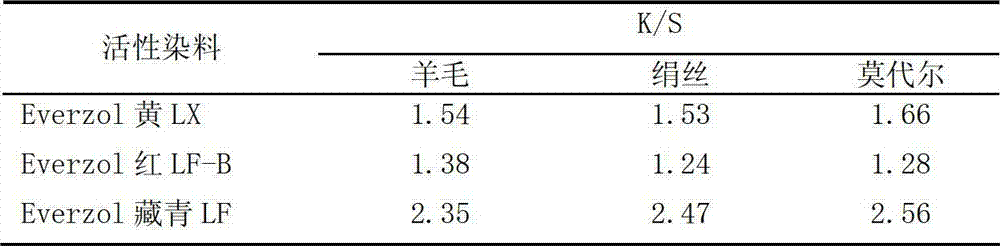

[0032] This example changes the mixing ratio of wool / spun silk / modal mixed loose fiber, reactive dye species, pretreatment and dyeing formula and process to carry out dyeing experiments.

[0033] Step 1: Reductive bleaching and oxidative bleaching pretreatment

[0034] The formula of reduction bleach treatment solution is as follows: the concentration of hydrosulfite is 4g / L, the concentration of sodium silicate is 1g / L, the treatment is started at room temperature, the temperature is raised to 80°C at 2°C / min for 40 minutes, and the reduction bleach is washed with water.

[0035] The formula of the oxidative bleaching solution is as follows: hydrogen peroxide 8g / L, sodium silicate 0.4g / L, sodium bicarbonate 0.7g / L, start treatment at room temperature, heat up to 80°C at 2°C / min, and treat for 50 minutes.

[0036] Step 2: Dyeing with reactive dyes

...

Embodiment 3

[0043] In this embodiment, wool / spun silk / modal mixed loose fibers with a mixing ratio of 70:12:18 are dyed navy blue. In this embodiment, the dye species of the reactive dye used is changed to dye dark colors.

[0044] Step 1: According to the formula and process of Example 1, the three mixed loose fibers to be dyed are subjected to pre-treatment of reduction bleaching and oxidation bleaching.

[0045] Step 2: Reactive Dye Dyeing

[0046] Wool / spun silk / modal mixed loose fiber after pretreatment, dyed with Everzol black ED-R.

[0047] The formula of the dyeing solution is: dye dosage 6% (o.w.f.), ethoxy fatty acid amine derivative leveling agent dosage 0.8g / L, sodium sulfate dosage 70g / L, soda ash dosage 6g / L. Add leveling agent and dye in cold water and run for 10 minutes; add sodium sulfate and run for 10 minutes; heat up to 70°C at 2°C / min, add soda ash twice after running for 10 minutes, and continue dyeing for 50 minutes. After dyeing, rinse with clean water, wash wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com