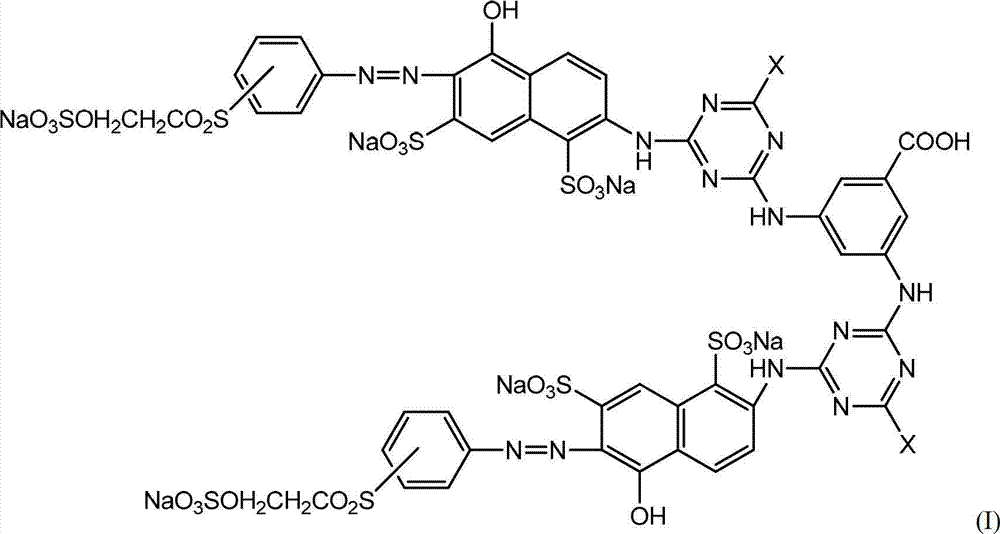

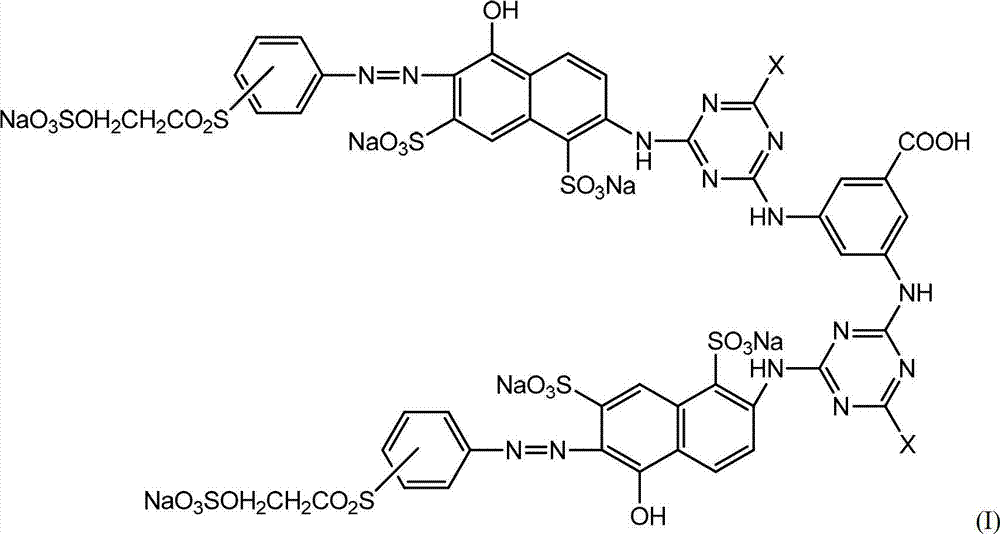

Reactive orange dye and preparation method thereof

A reactive orange and dye technology, applied in the field of dyes, can solve the problems of unfavorable deep dyeing and low dye fixation rate, and achieve the effects of good salt and alkali resistance, high solubility and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a) Add 1 mole of 25% para-ester solution with a pH of 6.0 to 7.0, adjust the pH to 7.5 to 8.0 with soda ash, add 1 mole of 30% sodium nitrite solution, stir well, and control it for 1 hour to evenly add to Use 2.5 moles of hydrochloric acid and ice water in a reaction kettle, under stirring, control the temperature at 0-5°C, keep a slight excess of nitrous acid, and balance it with sulfamic acid after reacting for 0.5 hours. Add sodium acetate to adjust to PH3.0~3.5, set aside.

[0022] b) Prepare 1.01 moles of sulfonated J acid into a solution with a concentration of 20% and a pH of 6.5~7.0, add ice and the first part of quantitative liquid caustic soda (2 moles) at a temperature of 3-5°C, quickly add diazonium salt, and add to Halfway through, add the second part of liquid caustic soda (1 mole) at the same time, control the temperature at 10-12°C, add PH=7.8-8.1, and react for 3 hours to measure the end point of diazo disappearance. Adjust the pH to 5.5~6.0 with hydr...

Embodiment 2

[0026] In the example 1a), the para-ester component is changed to the meta-ester, and other reaction procedures and proportioning ratios are unchanged to obtain a novel active orange dye solution with a chloro-s-triazine and vinyl sulfone active groups in the molecular structure. Nanofiltration membrane concentration (detection after recrystallization, m / z: 1729.80), continue to add dye solution according to the proportion of 15% of the weight after drying, add Yuanming powder, and 2% dustproof agent for spray drying, to obtain commercial dyes .

[0027] The dye can be used in exhaust dyeing, continuous pad dyeing, cold batching and wet short steaming process, moderate reactivity, high product solubility, 20°C solubility greater than 200g / l, 1 / 1 dyeing depth: light fastness level 5, soaping fastness 4-5 grades, perspiration fastness 4~5 grades, chlorine water immersion fastness grade 4, dry rubbing fastness 4~5 grades, wet rubbing fastness 4 grades, ironing fastness grade 4, p...

Embodiment 3

[0029] Cool the color base of the dye in Example 1b) to 0°C, add cyanuric fluoride, keep the temperature at 0~2°C, use 20% soda ash to keep the pH value at 6.0~6.5, add time for 1 hour, and keep the conditions after adding Reaction, control the disappearance of chromophore as the end point. Added 1,3-diaminobenzoic acid, keep pH6.5~7.0 with dry powder baking soda, heat up to 25~35℃, keep pH reaction for 4 hours, pH is stable, used for concentration and purification of nanofiltration membrane, cyanuric fluoride and 1,3-diaminobenzoic acid actual dosage is 1.04 moles and 0.52 moles of color and yield respectively.

[0030] After drying the dye solution, add sodium lignosulfonate and 3% dustproof agent according to the mass ratio of 25%, and spray dry to obtain commercial dyes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com