Rubber shoe foxing strip pressing machine

A technology of a laminating machine and a fence, which is applied in the directions of shoe-making machinery, footwear, and adhesive shoe parts, etc., can solve the problems of easy degumming of the fence, influence on the quality of rubber shoes, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

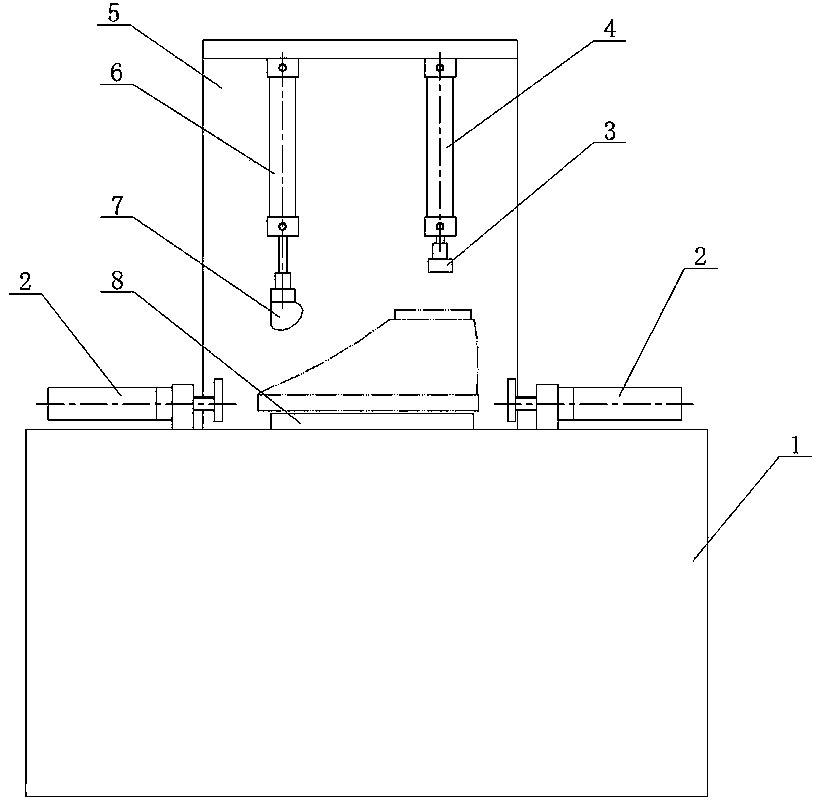

[0010] As shown in the figure, the rubber shoe skirt pressing machine of the present invention includes a workbench 1 and a backboard 5, a shoe last pad 8 is provided at the central position of the workbench 1, and four sets of shoe last pads 8 are arranged at the front, rear, left, and right sides. Flat pressure cylinder assembly 2, left and right plugs are arranged above the shoe last pad 8, the left plug 7 is connected to the piston rod of the left cylinder 6, the right plug 3 is connected to the piston rod of the right cylinder 4, and the left and right cylinders are on the back The front side of the plate 5 is fixedly installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com