Antiskid rubber composition for ice surface and production method thereof

A technology of anti-skid rubber and composition, applied in applications, shoe soles, clothing, etc., can solve the problems of poor storage stability of raw neoprene rubber, poor storage stability, increased Mooney viscosity, etc., to expand the effective use temperature range, Good anti-slip performance on ice surface, the effect of improving anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the present embodiment 1, the dynamic anti-slip rubber on the ice surface consists of the following components by weight:

[0044] Neoprene 15 parts

[0045] Solution polystyrene butadiene rubber T210015 parts

[0046] Carboxylated nitrile rubber X74055 parts

[0047] White carbon black 12 parts

[0048] 12 parts of waste rubber powder

[0049] Antiaging agent 10101 parts

[0050] Polyethylene glycol PEG40002 parts

[0051] Silane coupling agent Si692 parts

[0052] Polyethylene wax 2 parts

[0054] 2.5 parts of sulfur

[0055] Vulcanization accelerator D1 part

[0056] Vulcanization accelerator DM1 part.

[0057] All the rubber materials except zinc oxide, sulfur, and vulcanization accelerators are put into the banbury mixer for internal mixing, deglue at 105°C, and stand at room temperature for 24 hours, then knead on the double-roller open mill, and add accurately weighed oxide Zinc, sulfur, and vulcanization accelerator are ...

Embodiment 2

[0061] In this embodiment 2, the composition and production method of the dynamic anti-slip rubber on the ice surface are basically the same as the production method in embodiment 1, except that 20 parts of solution-polymerized styrene-butadiene rubber, 15 parts of white carbon black, and 15 parts of waste rubber powder share.

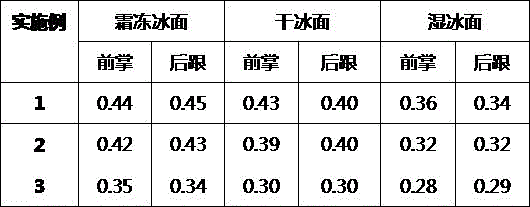

[0062] The anti-slip rubber product on ice prepared above has an anti-slip coefficient of 0.42 and 0.43 on the front palm on the frosty ice surface, 0.39 and 0.40 on the heel on the dry ice surface, and 0.39 and 0.40 on the heel on the wet ice surface. 0.32 followed by 0.32.

Embodiment 3

[0064] In this embodiment 3, the composition of dynamic anti-slip rubber on the ice surface, the production method are basically the same as the production method in embodiment 1, except that 50 parts of carboxylated nitrile rubber, 10 parts of white carbon black, and 10 parts of waste rubber powder share.

[0065] The anti-slip rubber product on ice surface prepared above has an anti-slip coefficient of 0.35 on the front palm and 0.34 on the heel on the frosty ice surface, 0.30 on the front palm and 0.30 on the heel on the dry ice surface, and 0.30 on the front palm on the wet ice surface. 0.28 followed by 0.29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com