Modifed asphalt waterproof curling material of environmental-protective plastic

A technology of asphalt waterproofing membrane and modified asphalt, which is applied in the field of building materials manufacturing, can solve the problems of poor quickness and tensile strength, short effective working life, poor aging resistance, etc., so as to reduce product cost, improve product performance and improve product performance. The effect of low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

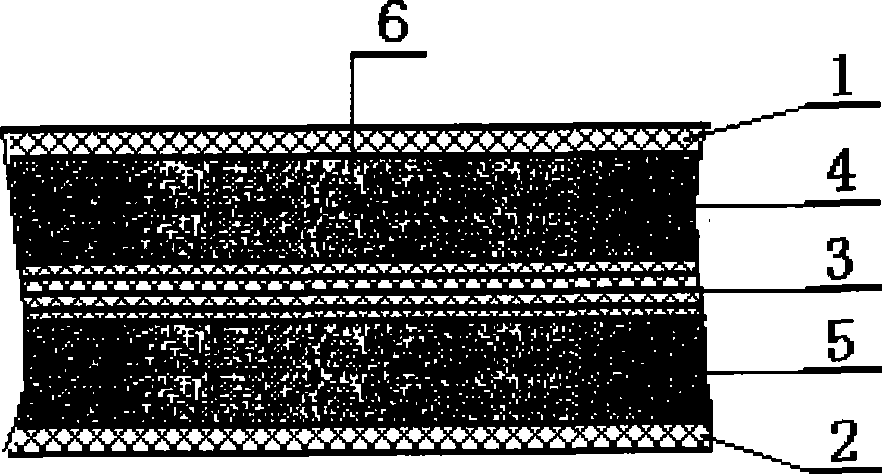

Image

Examples

Embodiment 1

[0014] Example 1 Low temperature difference environmental products

[0015] Rubber compound formula: 90# asphalt 28%, 10# asphalt 28%, thermoplastic styrene butadiene rubber 1%, polypropylene 4%, waste rubber powder 3%, waste woven bag 1%, waste engine oil 5%, heavy calcium 30%, A total of 100 copies.

[0016] Product performance: low temperature -5 ℃ qualified, high temperature 105 ℃ qualified.

Embodiment 2

[0017] Example 2 Environmental products with medium temperature difference

[0018] Rubber compound formula: 90# asphalt 25%, 10# asphalt 25%, thermoplastic styrene-butadiene rubber 3%, polypropylene 6%, waste rubber powder 7%, waste woven bag 3%, waste engine oil 7%, heavy calcium 24%, A total of 100 copies.

[0019] Product performance: low temperature -8 ℃ qualified, high temperature 115 ℃ qualified.

Embodiment 3

[0020] Example 3 High temperature difference environment products

[0021] Rubber compound formula: 90# asphalt 23%, 10# asphalt 23%, thermoplastic styrene butadiene rubber 4%, polypropylene 10%, waste rubber powder 10%, waste woven bag 5%, waste engine oil 10%, heavy calcium 15%, A total of 100 copies.

[0022] Product performance: low temperature -15 ℃ qualified, high temperature 130 ℃ qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com