Special sizing material for foaming rubber sole

A technology of foamed rubber and rubber materials, applied in shoe soles, applications, footwear, etc., can solve problems such as inability to apply shoe outsoles, unsuitable upper injection soles, insufficient strength of rubber soles, etc., to achieve microsphere particle size Uniform distribution, smooth sole appearance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

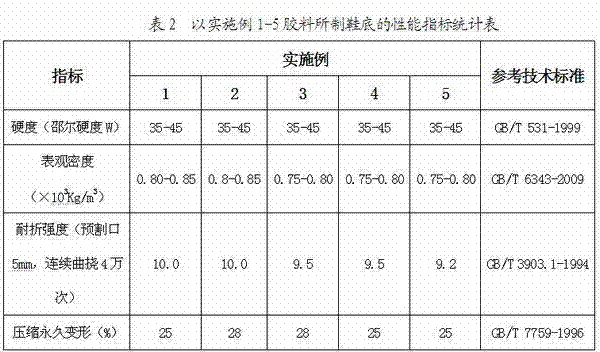

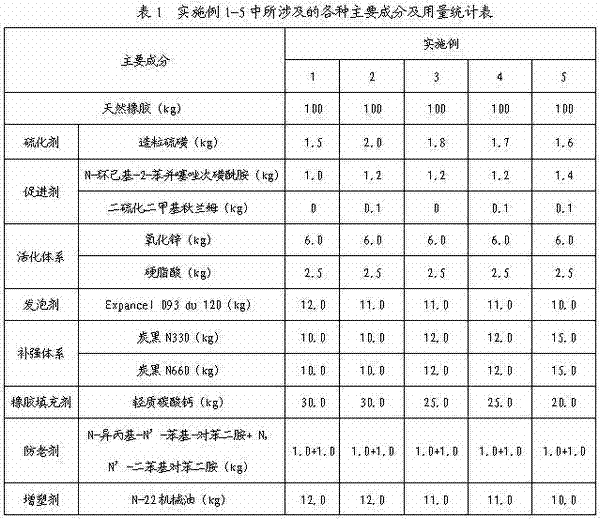

[0061] Embodiment 1-5 is respectively a kind of sizing material for foam rubber soles, and its raw material ratio is as shown in Table 1:

[0062]

[0063] The preparation method of the sizing material for foamed rubber soles in the embodiment 1-5 is carried out according to the following steps respectively

[0064] (1) Mastication of natural rubber

[0065] The natural rubber is put into the 450-type open mill for masticating, and the plasticity is required to be 0.50-0.60, so as to obtain natural rubber with satisfactory plasticity;

[0066] (2) Preparation for weighing raw materials

[0067] Accurately weigh the masticated natural rubber and other required raw materials according to the formula requirements, and set aside;

[0068] (3) Compound mixing

[0069] Put the masticated natural rubber, active agent, anti-aging agent, carbon black, plasticizer and other raw materials into the internal mixer for internal mixing. When the temperature of the rubber material reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com