Rubber shoes surrounding strip press fit machine capable of improving press fit quality

A pressing machine and pressing mechanism technology, which is applied in the direction of machines connecting welts, footwear, clothing, etc., can solve the problems of inability to realize all-round pressing, single function, and inability to achieve re-pressing of the enclosure, etc. Achieve improved design, high feasibility, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

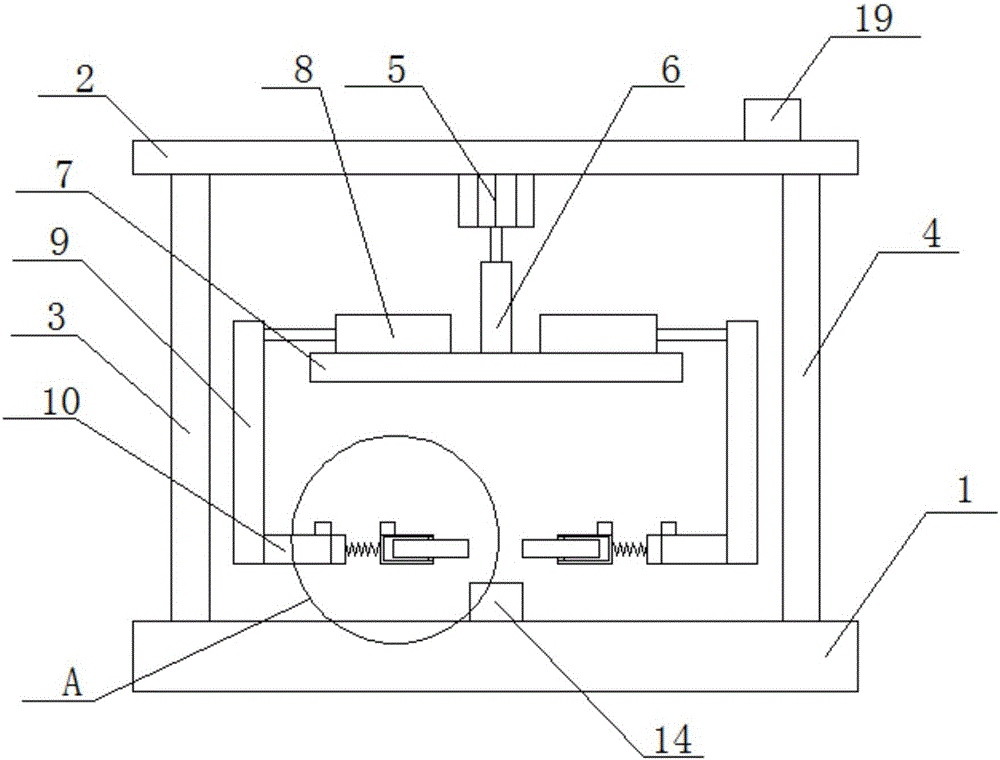

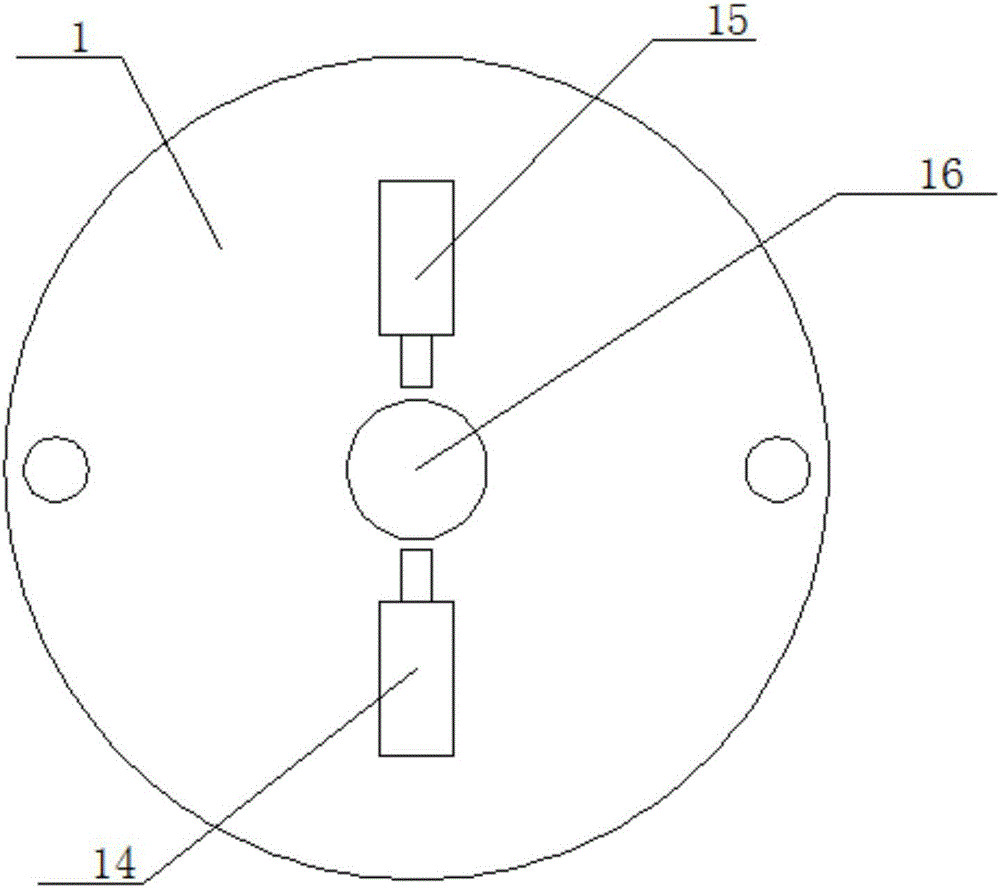

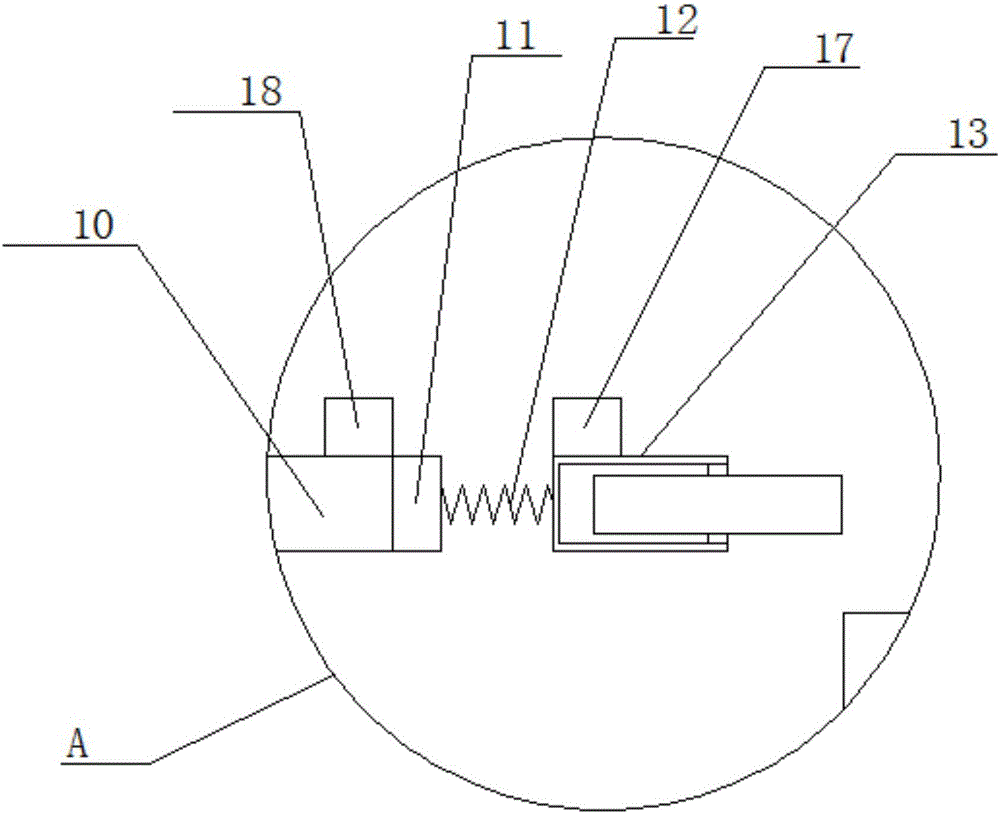

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] like Figure 1-3 As shown, a rubber shoe skirt pressing machine with improved pressing quality includes a base 1, a top plate 2, a first pillar 3, a second pillar 4, a first cylinder 14, a second cylinder 15, and a shoe mold support plate 16 , rotating mechanism, strengthened pressing mechanism and PLC;

[0023] The base 1 is connected to the top plate 2 through the first pillar 3 and the second pillar 4, the first pillar 3 and the second pillar 4 are all vertically arranged, the first cylinder 14, the second cylinder 15 and the shoe mold support The plates 16 are all located on the base 1, the output shafts of the first cylinder 14 and the second cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com