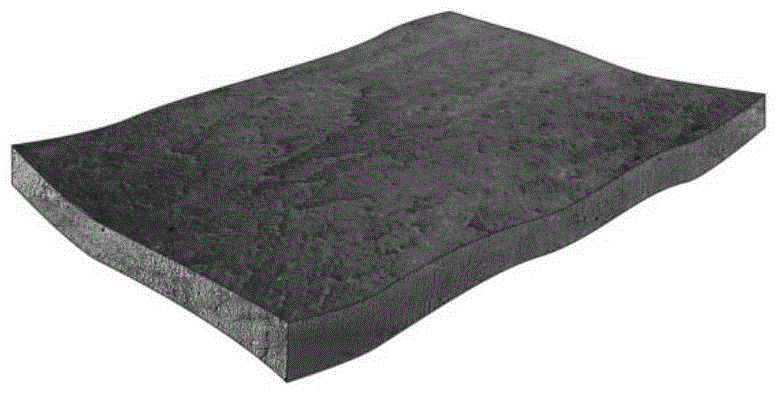

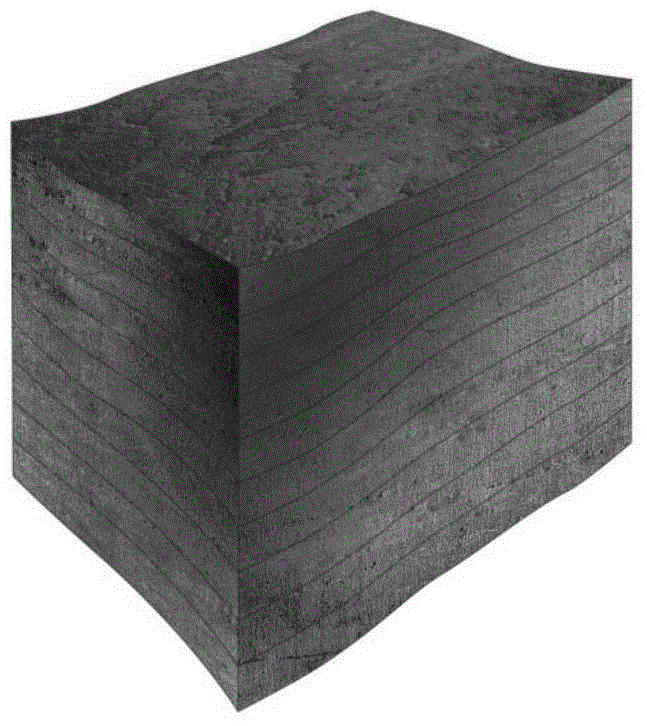

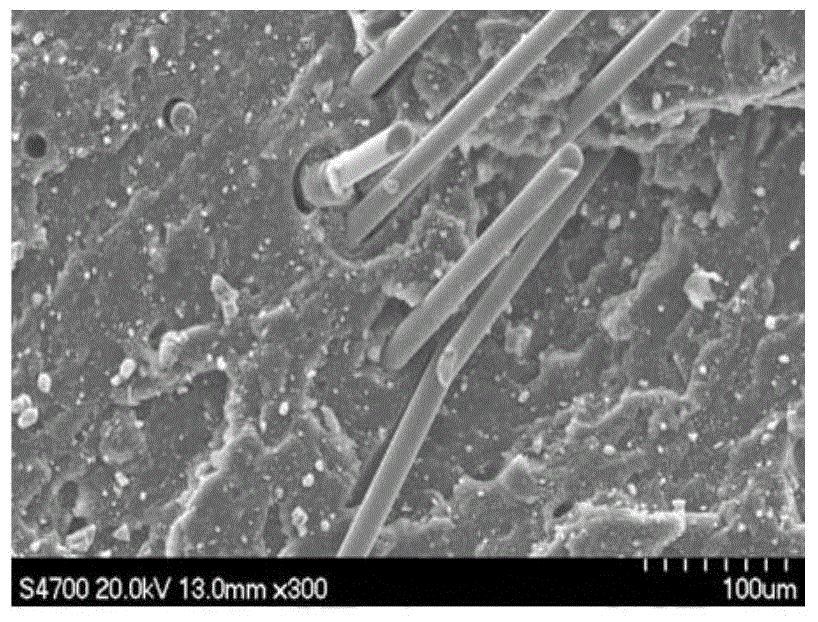

Directionally-arranged short-fiber composite rubber non-slip shoe sole material and preparation method thereof

A composite rubber and short fiber technology, which is applied in the field of shoemaking and rubber, can solve the problems of lack of anti-skid performance, reduction of dry anti-skid performance and wear resistance of soles, poor low temperature performance, etc., to ensure wear resistance and reduce Fall incidents, effect of improved anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] 1) First prepare the rubber compound:

[0096] a) Kneading 80 phr natural rubber and 20 phr butadiene rubber on an open mill using the shear force of the twin-roll mill for 5 minutes to form a smooth roll rubber and then cut the rubber for use.

[0097] b) Relax the roller pitch to 8~10mm, put the rubber covered in step a) into the roller pitch for 1 min, then add 30phr carbon black N220, 5phr engine oil, 1.5phr accelerator DM, 1phr accelerator CZ, 0.5phr accelerator D. Add 1phr antioxidant 4010, 0.5phr antioxidant RD, 0.5phr antioxidant MB, and 1.5phr dispersant FS-12. After the small materials are completely put in, then mix for 3~5min, and then add 2phr of sulfur. Continue mixing for 2 minutes; adjust the roller pitch to 2mm, repeat thinning and triangulation for 3 to 4 times, adjust the roller pitch to 10mm to eject the sheet, cool to room temperature 20℃ and park for 8 hours to obtain the rubber compound;

[0098] Then prepare compound film:

[0099] After adjusting the r...

Embodiment 2

[0105] 1) First prepare the rubber compound:

[0106] a) After kneading 90 phr natural rubber and 10 phr butadiene rubber on an open mill with the shear force of the double-roll mill for 5 minutes, make it form a smooth roll rubber and cut the rubber for use.

[0107] b) Relax the roller pitch to 8~10mm, put the rubber covered in step a) into the roller pitch for 1min, then add 25phr carbon black N220, 5phr engine oil, 1.5phr accelerator DM, 1phr accelerator CZ, 0.5phr accelerator D. Add 1phr antioxidant 4010, 0.5phr antioxidant RD, 0.5phr antioxidant MB, and 2phr dispersant FS-12. After the small materials are completely put in, then mix for 3~5min, then add 2.5phr sulfur, and wait for it to be completely added. Continue mixing for 2 minutes; adjust the roller pitch to 2mm, repeat thinning and triangulation for 3 to 4 times, adjust the roller pitch to 10mm to eject the sheet, cool to room temperature 20℃ and park for 8 hours to obtain the rubber compound;

[0108] Then prepare comp...

Embodiment 3

[0114] 1) First prepare the rubber compound:

[0115] a) Knead 80 phr natural rubber and 20 phr butadiene rubber on an open mill with the shear force of the twin-roll mill for 5 minutes to form a smooth roll rubber and cut the rubber for use.

[0116] b) Relax the roller pitch to 8~10mm, put the roller rubber obtained in step a) into the roller pitch for 1min, then add 20phr carbon black N220, 5phr engine oil, 1.5phr accelerator DM, 1phr accelerator CZ, 0.5phr accelerator D. Add 1phr antioxidant 4010, 0.5phr antioxidant RD, 0.5phr antioxidant MB, and 3phr dispersant FS-12. After the small materials are fully put in, then mix for 3~5min, then add 2phr of sulfur, and continue after adding completely Mixing for 2 minutes; adjust the roller pitch to 2mm, repeat the thinning and triangulation for 3 to 4 times, adjust the roller pitch to 10mm to discharge the sheet, cool to room temperature 20℃ and park for 8 hours to obtain the rubber compound;

[0117] Then prepare compound film:

[0118...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acron wear | aaaaa | aaaaa |

| Acron wear | aaaaa | aaaaa |

| Acron wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com