Anti-skid rubber sole and preparation method thereof

A kind of anti-skid rubber and anti-skid technology, applied in the direction of soles, footwear, other household appliances, etc., can solve the problems of lack of stable manufacturers, difficult to industrialize production, high price, etc., to improve the anti-skid performance of soles, good wear resistance, Good material processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] In the present embodiment, a kind of preparation method of antiskid rubber sole is characterized in that, comprises the steps:

[0064] Step (1): Prepare the anti-slip premixed rubber, 61 parts by weight of NBR / PVC emulsion co-precipitation alloy 3330G, 35 parts of low melting point polyamide (DSC melting temperature 110 ° C), compatibilizer styrene-maleic anhydride 4 parts of copolymer, kneaded on a two-roll mill, and then uniformly released into sheets to obtain anti-skid premixed rubber;

[0065] Step (2): Prepare a non-slip rubber sheet, which is prepared from the following components in the following parts by weight:

[0066] Non-slip premixed glue 40 parts

[0067] Natural rubber 3L 20 parts

[0068] Solution polystyrene butadiene rubber T2000R 22 parts

[0069] Bromobutyl rubber 2030 8 parts

[0070] Silica 20 parts

[0071] Antiager 1010 0.7 parts

[0072] Polyethylene glycol PEG4000 1.6 parts

[0073] Silane coupling agent Si 69 1.5 parts

[0074] Polye...

Embodiment 2

[0085] In the present embodiment, the preparation method of a kind of non-slip rubber sole is basically the same as the preparation method in Example 1, the difference is:

[0086] In step (1): the DSC melting temperature of the low melting point polyamide is 80°C.

[0087] In step (2): 25 parts of styrene-butadiene rubber are dissolved in solution, and the degumming temperature is 110°C.

[0088] In step (3): the deflation time is 4 seconds, the descending time is 4 seconds, the deflation times are 3 times, the pressure is 16.5 MPa, and the vulcanization time is 210 seconds.

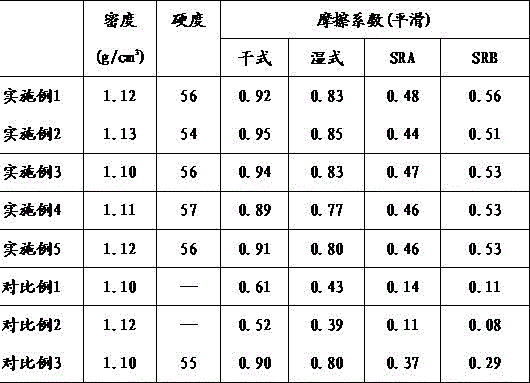

[0089] A kind of non-slip rubber sole prepared above, density 1.13g / cm 3 , Hardness 54A, dry friction coefficient 0.95, wet friction coefficient 0.85, SRA friction coefficient 0.44, SRB friction coefficient 0.51.

Embodiment 3

[0091] In the present embodiment, the preparation method of a kind of non-slip rubber sole is basically the same as the preparation method in Example 1, the difference is:

[0092] In step (1): 40% (mass ratio) of PVC content in the NBR / PVC emulsion co-precipitation alloy, 41% (mass ratio) of the acrylonitrile content of NBR in the NBR / PVC emulsion co-precipitation alloy; DSC melting of low melting point polyamide The temperature is 100°C.

[0093] In step (2): 18 parts of natural rubber and 23 parts of solution-polymerized styrene-butadiene rubber.

[0094] In step (3): the deflation time is 5 seconds, and the descending time is 5 seconds.

[0095] A kind of non-slip rubber sole prepared above, density 1.10g / cm 3 , Hardness 56A, dry friction coefficient 0.94, wet friction coefficient 0.83, SRA friction coefficient 0.47, SRB friction coefficient 0.53.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com