Ultrahigh adhesion strength rubber shoe surrounded strip adhesive as well as preparation method and application

A technology of adhesion strength and adhesives, applied in the direction of natural rubber adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of unstable adhesion strength, affecting production efficiency, slow drying speed, etc. problems, to achieve the effect of increasing permeability and brushing performance, saving production time, and improving adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

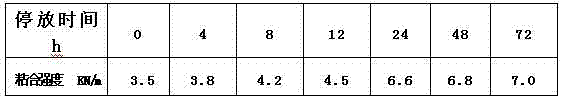

[0052] Embodiment 1 of the present invention: ultra-high adhesive strength rubber shoes enclosure adhesive, calculated in parts by weight, it comprises 100 parts of natural rubber, 4 parts of vulcanization accelerators (every 4 parts of vulcanization accelerators are made of 0.7 parts of accelerator H , 1.1 parts of accelerator CZ, 1.8 parts of accelerator DM and 0.4 parts of accelerator D), 1.5 parts of resorcinol, 0.4 parts of peptizer, 2.5 parts of sulfur, 8.5 parts of vulcanization activator (every 8.5 parts of vulcanization activator It consists of 0.5 parts of tertiary stearic acid and 8 parts of nano zinc oxide), 1.2 parts of white carbon black, 0.8 parts of anti-aging agent, 8 parts of binder A and 125 parts of 120# solvent gasoline.

[0053] The preparation method of the super-high adhesive strength rubber shoe enclosure adhesive is to masticate 2 parts of natural rubber to make the plasticity reach 0.45-0.55, then add accelerator H, resorcinol and peptizer, and thin ...

Embodiment 2

[0055] Embodiment 2 of the present invention: ultra-high adhesive strength rubber shoes enclosure adhesive, calculated in parts by weight, it comprises 95 parts of natural rubber, 3.5 parts of vulcanization accelerators (every 4 parts of vulcanization accelerators are made of 0.7 parts of accelerator H , 1.1 parts of accelerator CZ, 1.8 parts of accelerator DM and 0.4 parts of accelerator D), 1.3 parts of resorcinol, 0.3 parts of peptizer, 2.3 parts of sulfur, 8 parts of vulcanization activator (each 8.5 parts of vulcanization activator It consists of 0.5 parts of tertiary stearic acid and 8 parts of nano zinc oxide), 1 part of white carbon black, 0.7 parts of anti-aging agent, 7.5 parts of binder A and 120 parts of 120# solvent gasoline.

[0056] The preparation method of the super-high adhesive strength rubber shoe enclosure adhesive is to masticate 2 parts of natural rubber to make the plasticity reach 0.45-0.55, then add accelerator H, resorcinol and peptizer, and thin Pas...

Embodiment 3

[0058] Embodiment 3 of the present invention: ultra-high adhesive strength rubber shoes enclosure adhesive, calculated in parts by weight, it comprises 105 parts of natural rubber, 4.5 parts of vulcanization accelerators (every 4 parts of vulcanization accelerators are made of 0.7 parts of accelerator H , 1.1 parts of accelerator CZ, 1.8 parts of accelerator DM and 0.4 parts of accelerator D), 1.7 parts of resorcinol, 0.5 parts of peptizer, 2.7 parts of sulfur, 9 parts of vulcanization activator (every 8.5 parts of vulcanization activator It consists of 0.5 parts of tertiary stearic acid and 8 parts of nano zinc oxide), 1.4 parts of white carbon black, 0.8 parts of anti-aging agent, 8.5 parts of binder A and 130 parts of 120# solvent gasoline.

[0059] The preparation method of the super-high adhesive strength rubber shoe enclosure adhesive is to masticate 2 parts of natural rubber to make the plasticity reach 0.45-0.55, then add accelerator H, resorcinol and peptizer, and thin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com