Formula and preparation method of extinction type shoe rubber

A matte, shoe technology, used in applications, footwear, apparel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

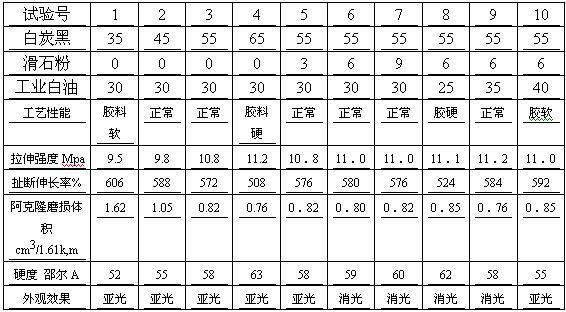

Image

Examples

Embodiment 1

[0047] Embodiment 1 of the present invention: the formula of extinction type shoe rubber, it comprises 60 parts of natural rubbers, 40 parts of solution polystyrene-butadiene rubbers, 1.8 parts of sulfur, by 0.7 parts of accelerator DM, 1.3 parts of accelerators CZ and 0.3 parts of accelerators 2.3 parts of vulcanization accelerator composed of agent PX, 9 parts of vulcanization activator composed of 4 parts of zinc carbonate and 5 parts of stearic acid, 35 parts of industrial white oil, 6 parts of diethylene glycol, 55 parts of precipitated silica, 0.2 1 part of salicylic acid as an anti-scorch agent, 1.2 parts of mold release agent 935P, 3 parts of calcium-based grease, 1.3 parts of anti-aging agent CD, 6 parts of talcum powder and 0.05 part of coloring agent.

[0048]The preparation method of the rubber for matting type shoes is to refine the natural rubber according to the parts by weight of the above formula, so that the Vickers plasticity can reach 0.30-0.40 to obtain the...

Embodiment 2

[0049] Embodiment 2 of the present invention: the prescription of extinction type shoe rubber, it comprises 45 parts of natural rubbers, 35 parts of solution polystyrene-butadiene rubbers, 1.5 parts of sulfur, by 0.5 part of accelerator DM, 0.9 part of accelerator CZ and 0.1 part of accelerator 1.5 parts of vulcanization accelerator composed of agent PX, 6 parts of vulcanization activator composed of 2 parts of zinc carbonate and 4 parts of stearic acid, 30 parts of industrial white oil, 5 parts of diethylene glycol, 50 parts of precipitated silica, 0.1 1 part of salicylic acid as an anti-scorch agent, 1 part of release agent 935P, 2 parts of calcium base grease and 1 part of anti-aging agent, 3 parts of talcum powder and 0.1 part of coloring agent.

[0050] The preparation method of the rubber for matting type shoes is to refine the natural rubber according to the parts by weight of the above formula, so that the Vickers plasticity can reach 0.30-0.40 to obtain the plastic...

Embodiment 3

[0051] Embodiment 3 of the present invention: the formula of extinction type shoe rubber, it comprises 65 parts of natural rubbers, 55 parts of solution polystyrene-butadiene rubbers, 2.5 parts of sulfur, by 1.5 parts of accelerator DM, 2 parts of accelerators CZ and 0.5 parts of accelerators 4 parts of vulcanization accelerator composed of agent PX, 11 parts of vulcanization activator composed of 5 parts of zinc carbonate and 6 parts of stearic acid, 40 parts of industrial white oil, 7 parts of diethylene glycol, 60 parts of precipitated silica, 0.4 Parts of salicylic acid as an anti-scorch agent, 1.5 parts of release agent 935P, 4 parts of calcium-based fat, 1.5 parts of anti-aging agent and 10 parts of talcum powder.

[0052] The preparation method of the rubber for matting type shoes is to refine the natural rubber according to the parts by weight of the above formula, so that the Vickers plasticity can reach 0.30-0.40 to obtain the plasticized rubber; Mix rubber to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com