Modified abs special material for automobile and its production method

A production method and technology for special materials, applied in the field of formula design of modified ABS automotive special materials, can solve problems such as affecting the driver's vision, loss of mechanical properties, driver discomfort, etc. Good focus and the effect of improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

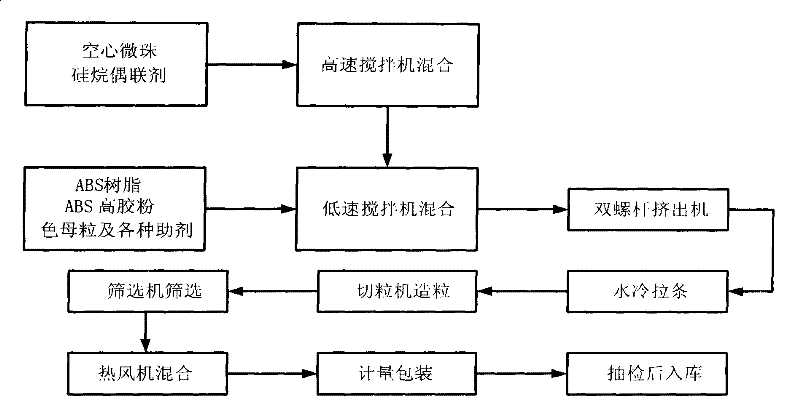

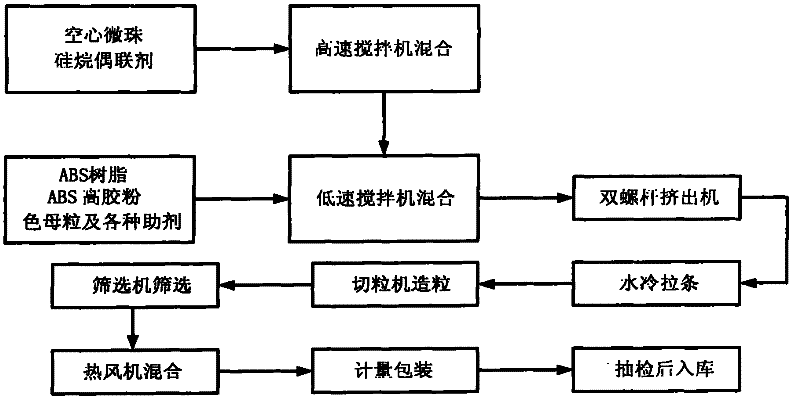

Method used

Image

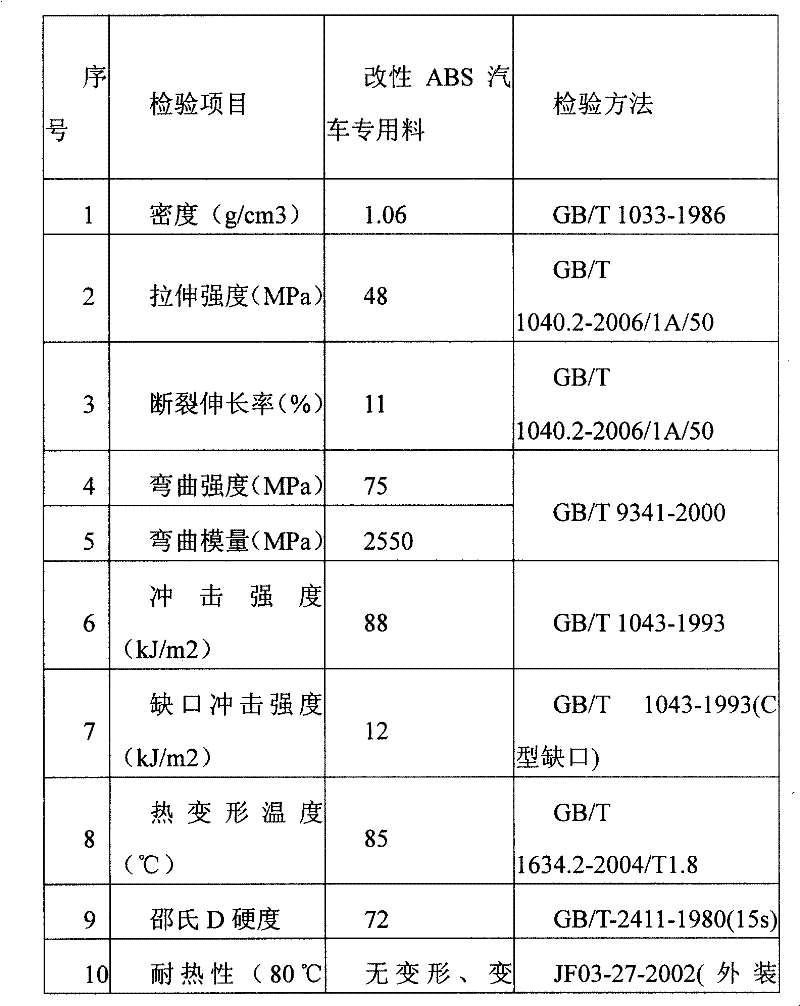

Examples

Embodiment 1

[0042] The formula of active filler hollow microspheres: 5kg of hollow microspheres, 0.05kg of silane coupling agent KH550;

[0043] Main formula: matrix resin ABS 100kg, high rubber powder ABS 4kg, antioxidant 0.3kg, anti-ultraviolet agent 0.2kg, black masterbatch 2kg;

Embodiment 2

[0045] The formula of active filler hollow microspheres: hollow microspheres 10kg, silane coupling agent KH550 0.1kg;

[0046] Main formula: matrix resin ABS 100kg, high rubber powder ABS 6kg, antioxidant 0.4kg, anti-ultraviolet agent 0.3kg, black masterbatch 2kg;

Embodiment 3

[0048]The formula of active filler hollow microspheres: hollow microspheres 15kg, silane coupling agent KH550 0.15kg;

[0049] Main formula: matrix resin ABS 100kg, high rubber powder ABS 8kg, antioxidant 0.4kg, anti-ultraviolet agent 0.4kg, black masterbatch 2kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com