Water soluble adhesive and preparation method thereof

An adhesive and water-soluble technology, applied in the field of water-soluble adhesives and their preparation, can solve the problems of low final adhesive strength, low initial adhesive strength, rubber shoe penetration, etc., and achieve the effect of long-term performance retention and anti-aging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

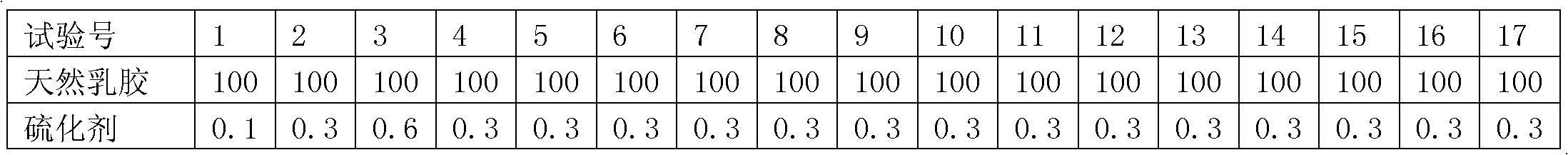

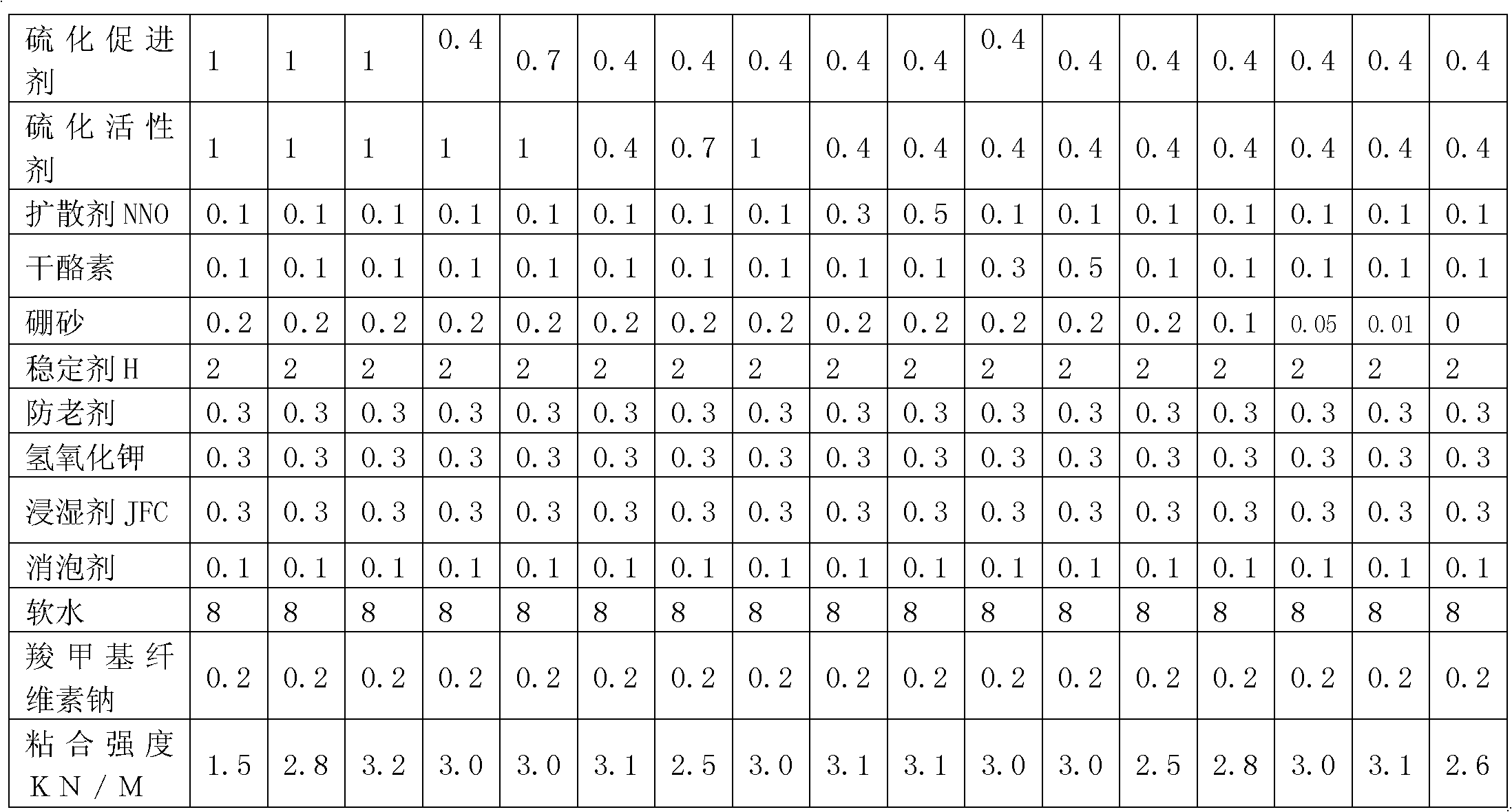

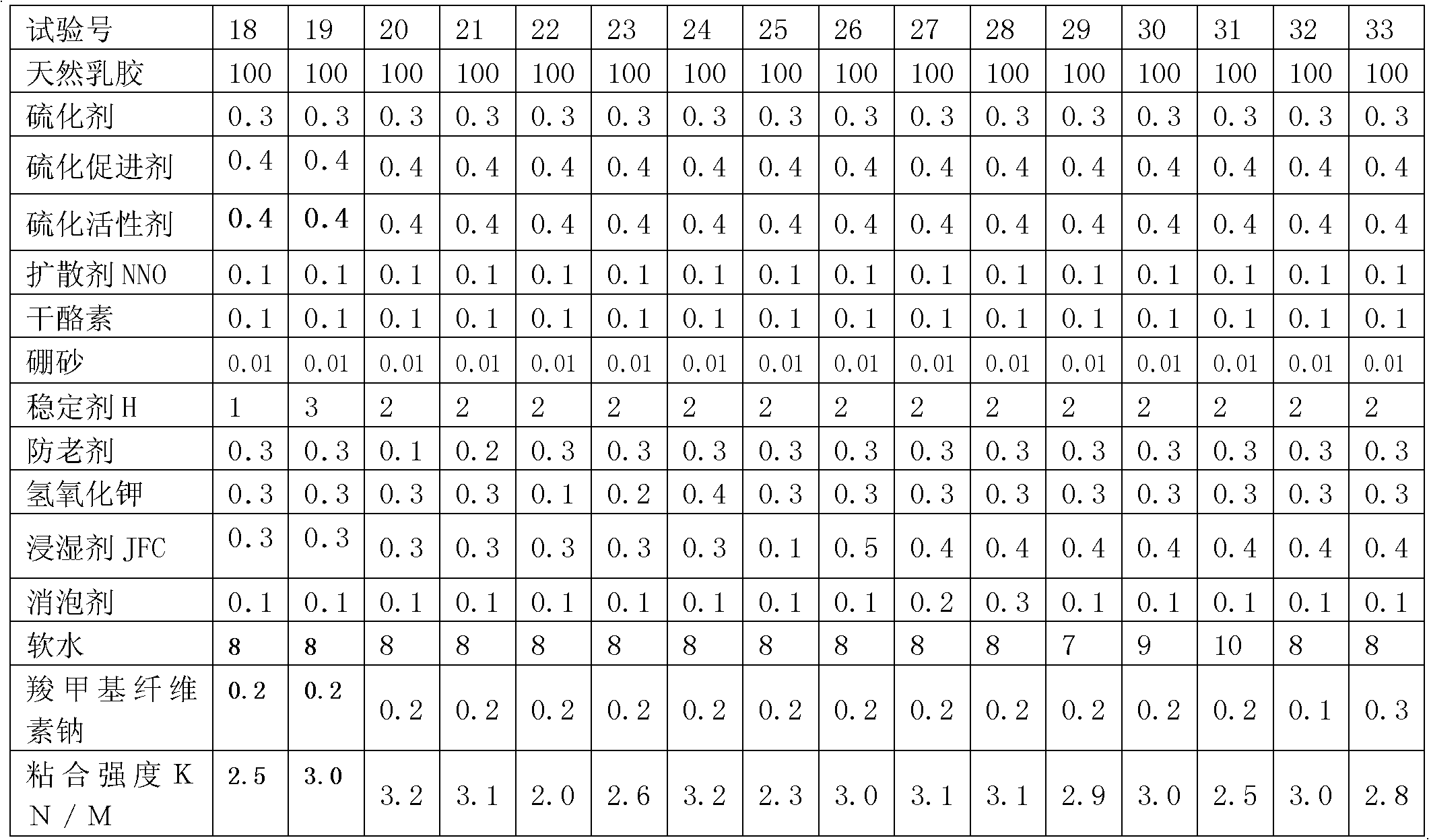

Examples

Embodiment 1

[0089] Embodiment 1 raw material: natural latex 100kg, soft water 8kg, rubber compounding agent (curing agent: sulfur 0.3kg, vulcanization accelerator M 0.4kg, vulcanization active agent: zinc oxide 0.4kg, diffusion agent 0.1kg, casein 0.1kg, borax 0.01kg, stabilizer H 2kg), ammonia 1kg, potassium hydroxide 0.3kg, sodium carboxymethyl cellulose 0.2kg, wetting agent JFC 0.4kg, antioxidant 4010NA 0.3kg, defoamer 0.1kg, antifungal agent 0.004 kg

[0090] Preparation:

[0091](1) Preparation of ball milling liquid: dissolve potassium hydroxide with 3.2kg of soft water, then add sulfur, vulcanization accelerator M, zinc oxide, anti-aging agent, defoamer, diffusing agent, casein and borax in sequence, and then add 3.2kg of soft water, stirred evenly, and ball milled in a sealed ball mill tank for 24 hours to obtain a ball mill liquid. The total weight of ceramic balls in the ball mill tank is 8 kg, of which: the weight of ceramic balls with a diameter of 20-40mm is 6 kg, and the we...

Embodiment 2

[0097] Embodiment 2 raw materials: natural latex 100kg, soft water 7kg, rubber compounding agent (vulcanizing agent (sulfur) 1.0kg, vulcanization accelerator M 0.3kg, vulcanization active agent (active zinc oxide) 0.3kg, diffusion agent 0.3kg, casein 0.3 kg, borax 0.01kg, stabilizer H 1kg), ammonia water 2kg, potassium hydroxide 0.2kg

[0098] Preparation:

[0099] (1) The preparation of ball mill liquid: dissolve potassium hydroxide with the soft water of 2.8kg, then add vulcanizing agent, vulcanization accelerator, vulcanization active agent, diffusion agent, casein and borax successively, then add the soft water of 2.8kg, stir, Seal ball milling in a ball mill tank for 22 hours to obtain a ball mill liquid. The total weight of the ceramic balls in the ball mill tank is 8 kg, of which: the weight of ceramic balls with a diameter of 20-40 mm is 6 kg, and the weight of ceramic balls with a diameter of 10-15 mm is 2 kg. kg; the milling liquid should be used up within one hour ...

Embodiment 3

[0102] Embodiment 3 raw materials: natural latex 100kg, soft water 12kg, rubber compounding agent (vulcanizing agent 0.2kg, vulcanization accelerator 1.0kg, vulcanization active agent 1.0kg, diffusion agent 0.1kg, casein 0.1kg, borax 0.03kg, stabilizer 3kg ), ammonia water 0.5kg and potassium hydroxide 0.5kg, carboxymethyl cellulose sodium 0.5kg, wetting agent 3kg

[0103] (1) Preparation of ball mill liquid: dissolve potassium hydroxide with 40% soft water, then add vulcanizing agent, vulcanization accelerator, vulcanization active agent, diffusing agent, casein and borax successively, then add 40% soft water, stir, Seal ball milling in a ball mill tank for 28 hours to obtain a ball mill liquid. The total weight of the ceramic balls in the ball mill tank is 8 kg, of which: the weight of ceramic balls with a diameter of 20-40 mm is 6 kg, and the weight of ceramic balls with a diameter of 10-15 mm is 2 kg. kg; the milling liquid should be used up within one hour after leaving t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com