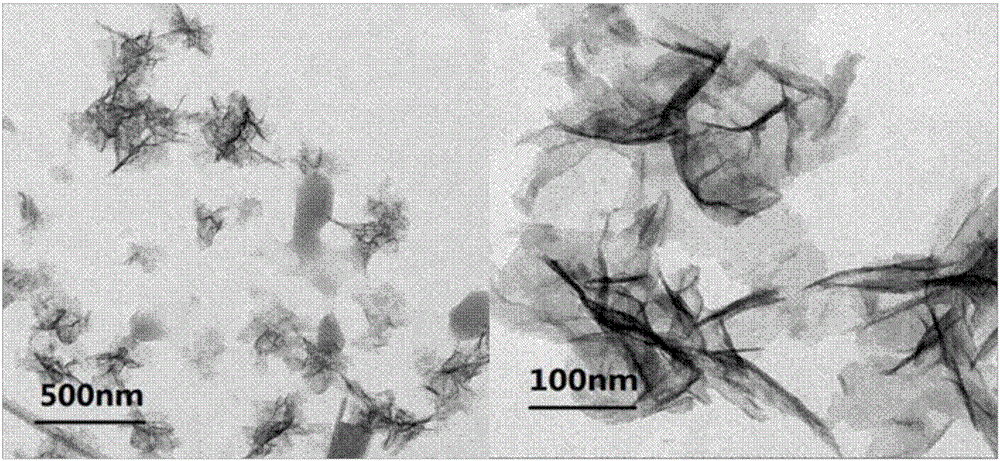

Three-dimensional network graphene for lithium battery and preparing method thereof

A three-dimensional network, graphene technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of difficulty in ensuring the purity of graphene, difficulty in industrial scale production, cumbersome preparation process, etc., and achieves low comprehensive cost, good crystallinity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Fully mix 2g of high-purity expanded graphite, 0.1g of sodium dodecylbenzenesulfonate, 0.1g of polyvinyl alcohol, 0.005g of polyoxypropanolamine ether defoamer and 95g of water, and pass the mixture through high-shear Cut emulsifier to obtain viscous few-layer graphene slurry;

[0043] (2) Add 0.01 g of sodium polyacrylate to the graphene slurry in step (1), shear at high speed for 2 hours to obtain a composite slurry, and coat the composite slurry on the metal aluminum foam porous material (micropores), Vacuumize the composite slurry to absorb into the pores;

[0044] (3) Place the metal aluminum foam porous material adsorbed with graphene slurry in step (2) in a high-temperature atmosphere (1200°C) protected by nitrogen gas, take it out after carbonization for 3 hours and cool it down, and then place the adsorbed three-dimensional network graphene The powdered metal aluminum foam porous material is placed in deionized water, stirred rapidly to suspend the graphen...

Embodiment 2

[0046] (1) Fully mix 5g of high-purity expanded graphite, 0.3g of sodium lauryl sulfate, 0.3g of polyvinylpyrrolidone, 0.01g of polyoxypropanolamine ether defoamer and 97.8g of water, and pass the mixture through high-shear The emulsifier obtains a viscous few-layer graphene slurry;

[0047] (2) Add 0.05g of sodium polyacrylate to the graphene slurry in step (1), emulsify for 1 hour to obtain a composite slurry, coat the composite slurry on the metal aluminum foam porous material (micropores), and vacuumize Adsorb the composite slurry into the pores;

[0048] (3) Put the metal aluminum foam porous material adsorbed with graphene slurry in step (2) in a high-temperature atmosphere protected by nitrogen at 1200°C, take it out after carbonization for 4 hours, and cool it, and then place the adsorbed three-dimensional network graphene powder The metal aluminum foam porous material is placed in deionized water, stirred rapidly to suspend graphene powder on the surface of deionized...

Embodiment 3

[0050] (1) Fully mix 3g of high-purity expanded graphite, 0.2g of sodium dodecylbenzenesulfonate, 0.2g of polyoxyethylene, 0.08g of polydimethylsiloxane defoamer and 96.5g of water, and pass the mixture through High-shear emulsifier to obtain viscous few-layer graphene slurry;

[0051] (2) Add 0.25g sodium carboxymethyl cellulose to the graphene slurry in step (1), stir vigorously for 1.5 hours to obtain a composite slurry, and coat the composite slurry on the metal aluminum foam porous material (microporous) On, vacuumize the composite slurry to absorb into the pores;

[0052] (3) Put the metal aluminum foam porous material adsorbed with graphene slurry in step (2) in a high-temperature atmosphere protected by nitrogen at 1200°C, take it out after carbonization for 4 hours, and cool it, and then place the adsorbed three-dimensional network graphene powder The metal aluminum foam porous material is placed in deionized water, stirred rapidly to suspend graphene powder on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com