Carbon cladded ferriferrous oxide negative electrode material of lithium ion battery and preparation method thereof

A carbon-coated ferric oxide and lithium-ion battery technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor particle size uniformity of nanoparticles, time-consuming and labor-intensive steps, and complicated steps, and achieve the degree of graphitization High, simple operation, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

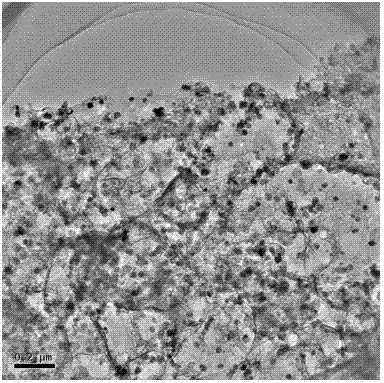

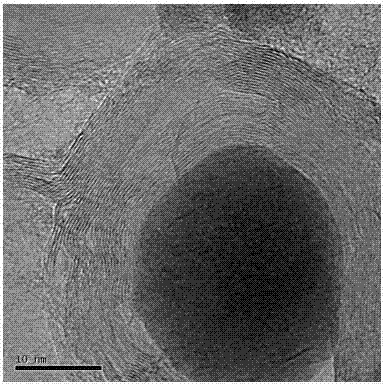

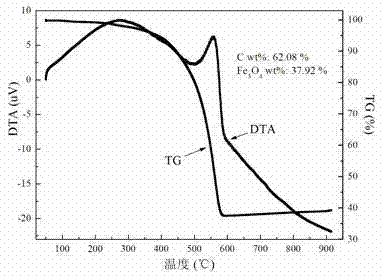

[0026]Weigh 1.2g of glucose, 0.808g of ferric nitrate and 11.1g of NaCl, dissolve the mixture in 50ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, and then use a 400W ultrasonic Sonicate for 15 minutes and mix well. Put the mixed solution into a vacuum drying oven at 80° C. for vacuum drying until a mixture is obtained. Grind the mixture, take 6g of the mixed powder and place it in the ark, put the ark in a tube furnace, and under the protection of Ar inert gas with a flow rate of 200ml / min, heat up to a temperature of 300°C at a heating rate of 10°C / min. After decomposing the source, keep it warm for 2 hours; then continue to pass in the Ar inert gas with a flow rate of 200ml / min, and raise the temperature to 750°C at a heating rate of 10°C / min, keep it warm for 2h for carbonization, and cool it under the protection of Ar atmosphere after the reaction to room temperature to obtain a calcined product. Colle...

Embodiment 2

[0029] In this embodiment, carbon coated Fe 3 o 4 The preparation process of the nanoparticles and the battery preparation process are the same as the first step of the embodiment, except that the calcination temperature is changed from 750°C to 700°C. The prepared lithium-ion battery was charged and discharged on the Blue Electric CT2001A battery tester. After 30 cycles at 1C (current density 24.5mA / g), the battery discharge specific capacity was 522mAhg -1 , after 100 cycles at 2C (current density 49mA / g), the discharge specific capacity of the battery is 181mAhg -1 , after 50 cycles at 5C (current density 122.5mA / g), the discharge specific capacity of the battery is 72mAhg -1 , its charge and discharge test curve is as follows Figure 8 shown. Utilize the electrochemical workstation that model is CHI660D to carry out cyclic voltammetry test to the battery that makes then, the voltage range of scanning is 0.01-3V, and scanning speed is 0.005mV, and scanning cycle is 5 ti...

Embodiment 3

[0031] Weigh 5g of sucrose, 0.808g of ferric nitrate and 11.1g of NaCl, dissolve the mixture in 50ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, and then sonicate with a 400W ultrasonic device 15min, mix well. Put the mixed solution into a vacuum drying oven at 80° C. for vacuum drying until a mixture is obtained. Grind the mixture, take 6g of the mixed powder and place it in the ark, put the ark into the tube furnace, first pass 400ml / min of Ar inert gas to remove the air, then use 400ml / min of Ar inert gas, and at 10°C / min The heating rate of min is raised to 400°C for carbon source decomposition, and after holding for 1 hour; then continue to pass in Ar inert gas with a flow rate of 400ml / min, and raise the temperature to 750°C at a heating rate of 10°C / min, and hold for 2 hours. Carbonization, after the reaction is completed, it is cooled to room temperature under the protection of Ar atmosphere to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com