Low temperature hydrothermal preparation method of biomass carbon microsphere / nanosphere

A biomass carbon, nanosphere technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable large-scale industrial production, unfavorable energy saving, safety issues, etc. The effect of rich oxygen-containing functional groups, high safety, and low hydrothermal carbonization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

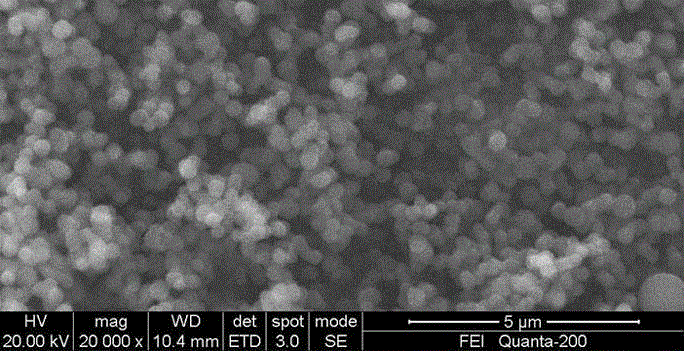

[0025] Example 1: Put 6 g of glucose into the polytetrafluoroethylene lining of a 100 mL reactor, weigh 0.9 g of urea and dissolve it in 60 mL of deionized water, then add it to the above polytetrafluoroethylene lining, stir with a glass rod to make it all Dissolve, then put into the stainless steel reaction kettle, tighten the reaction kettle, put it in the oven, set the reaction condition as: temperature 110 ° C, the reaction time is 12 h; after the reaction is finished, cool down to room temperature naturally, take out the polytetrafluoroethylene lining, separate it with a high-speed centrifuge, redisperse it with deionized water and 95% ethanol and wash it repeatedly until the supernatant is colorless, The resulting solid was dried to obtain 0.75 g of carbon nanospheres with a particle size of about 450 nm.

Embodiment 2

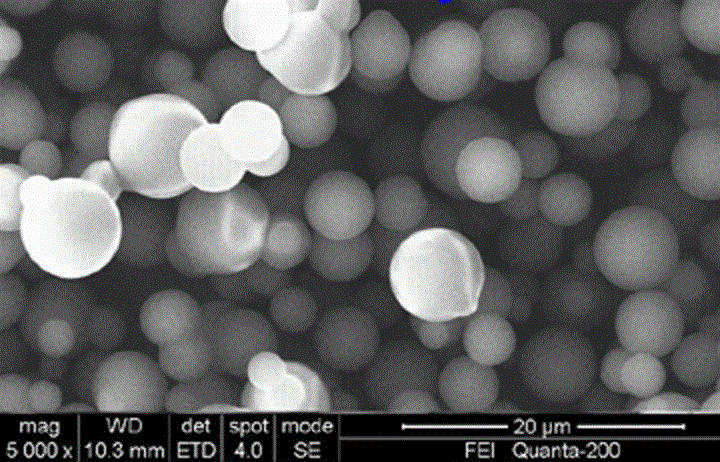

[0026] Example 2: Put 12 g of glucose into the polytetrafluoroethylene lining of a 100 mL reactor, weigh 5.27 ml of 25% ammonia water and dissolve it in 60 mL of deionized water, add it to the above polytetrafluoroethylene lining, and stir with a glass rod Make it all dissolve, then put it into a stainless steel reaction kettle, tighten the reaction kettle, put it in an oven, and set the reaction conditions as follows: temperature 130 ° C, the reaction time is 48 h; after the reaction is finished, cool down to room temperature naturally, take out the polytetrafluoroethylene lining, separate it with a high-speed centrifuge, redisperse it with deionized water and 95% ethanol and wash it repeatedly until the supernatant is colorless, The resulting solid was dried to obtain 3.55 g of carbon microspheres with a particle size of about 3 μm.

Embodiment 3

[0027] Example 3: Put 3 g of glucose into the polytetrafluoroethylene lining of a 100 mL reactor, weigh 0.09 g KOH and dissolve it in 60 mL of deionized water, then add it to the above polytetrafluoroethylene lining, and stir it with a glass rod to make it all Dissolve, then put it into a stainless steel reaction kettle, tighten the reaction kettle, put it in an oven, set the reaction conditions as follows: temperature 120 °C, the reaction time is 72 h; after the reaction is finished, cool down to room temperature naturally, take out the polytetrafluoroethylene lining, separate it with a high-speed centrifuge, redisperse it with deionized water and 95% ethanol and wash it repeatedly until the supernatant is colorless, The resulting solid was dried to obtain 0.85 g of carbon nanospheres with a particle size of about 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com