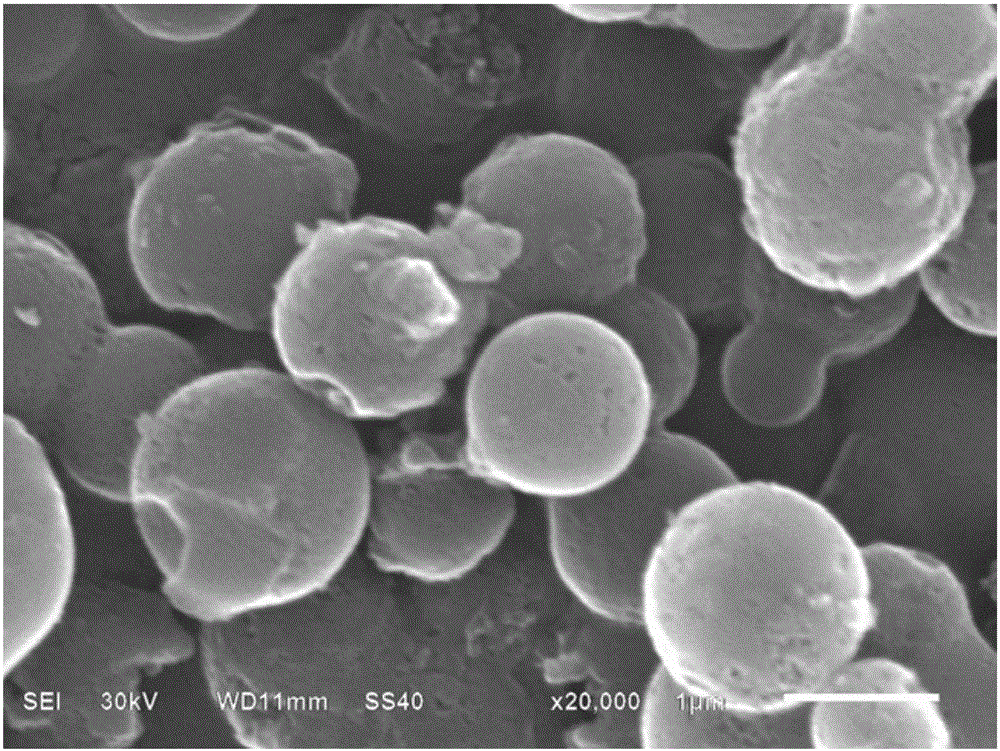

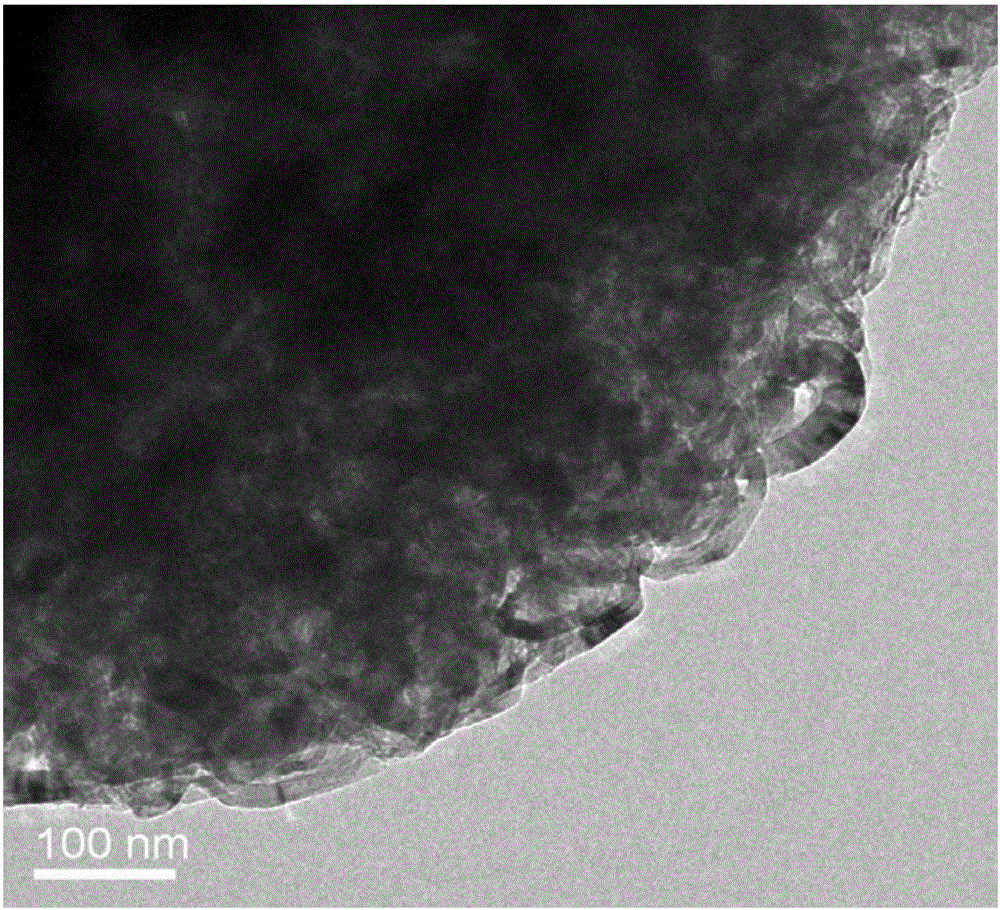

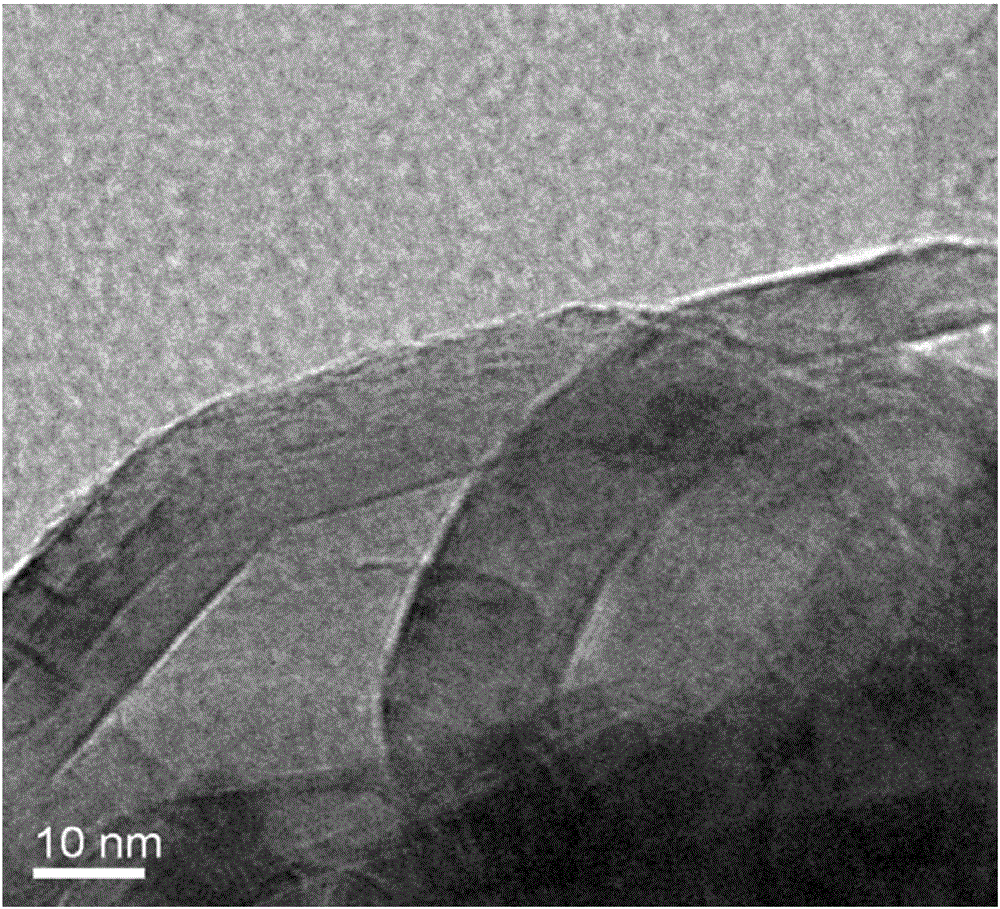

Highly-graphitized carbon nanowire ball material and preparation method thereof

A technology for graphitizing carbon and nanowires, applied in the field of carbon nanomaterials, can solve problems such as expensive graphitization furnaces, and achieve the effects of easy industrial production, wide application prospects, and low graphitization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve 10 g of sucrose in distilled water to make a solution with a concentration of 1 mol / L, transfer the solution to a high-pressure reactor with a volume filling rate of 0.5, and conduct a hydrothermal treatment at 180°C for 6 hours; filter the product with suction and wash and vacuum drying to obtain a hydrothermal carbon coke precursor.

[0046] (2) Prepare K with a concentration of 2mol / L 2 CO 3 Activator solution, then the hydrothermal carbon coke precursor prepared in step (1) is placed in the activator solution, wherein the mass ratio of the hydrothermal carbon coke precursor to the activator is 2:1, after the two are mixed, the Stir at room temperature for 60 minutes, then dry and grind it at 100°C to obtain a homogeneous mixture of hydrothermal carbon coke precursor and activator, then put the mixture in a porcelain boat and put it into an electric heating quartz tube furnace. At 99.9% N 2 Heat treatment at 800°C for 2 hours under gas protection, car...

Embodiment 2

[0050] (1) Mix 10g of β-cyclodextrin in 50mL of distilled water and stir, then transfer it to a high-pressure reactor with a volume filling rate of 0.5, and conduct a hydrothermal treatment at 200°C for 8 hours; filter the product, wash it, and dry it in vacuum. A hydrothermal carbon coke precursor is obtained.

[0051] (2) Prepare a NaOH activator solution with a concentration of 1mol / L, and then place the hydrothermal carbon coke precursor prepared in step (1) in the activator solution, wherein the mass of the hydrothermal carbon coke precursor and the activator The ratio is 4:1, the two are mixed and stirred at room temperature for 60 minutes, then dried and ground at 100°C to obtain a homogeneous mixture of hydrothermal carbon coke precursor and activator, and then the mixture is packed in a porcelain boat Put into the electric heating quartz tube furnace, in 99.9% CO 2 Heat treatment at 750°C for 3 hours under gas protection for carbonization and activation treatment, an...

Embodiment 3

[0056] (1) Dissolve 13.6 g of glucose in distilled water to form a solution with a concentration of 2 mol / L, transfer the solution to a high-pressure reactor with a volume filling rate of 0.5, and conduct a hydrothermal treatment at 190°C for 15 hours; filter the product with suction, After washing and vacuum drying, a hydrothermal carbon coke precursor is obtained.

[0057] (2) Prepare Na with a concentration of 1mol / L 2 CO 3 Activator solution, then the hydrothermal carbon coke precursor prepared in step (1) is placed in the activator solution, wherein the mass ratio of the hydrothermal carbon coke precursor to the activator is 6:1, after the two are mixed, the Stir at room temperature for 80 minutes, then dry and grind it at 100°C to obtain a homogeneous mixture of hydrothermal carbon coke precursor and activator, then put the mixture in a porcelain boat and put it into an electric heating quartz tube furnace. Heat treatment at 800°C for 3 hours under the protection of 99...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com