Method for preparing porous carbon ball composite absorbing material loaded with magnetic metal element

A composite wave absorbing material and magnetic metal technology, applied in electrical components, antennas and other directions, can solve the problems of high cost, complex process, low output, etc., and achieve the effects of convenient operation, simple process and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

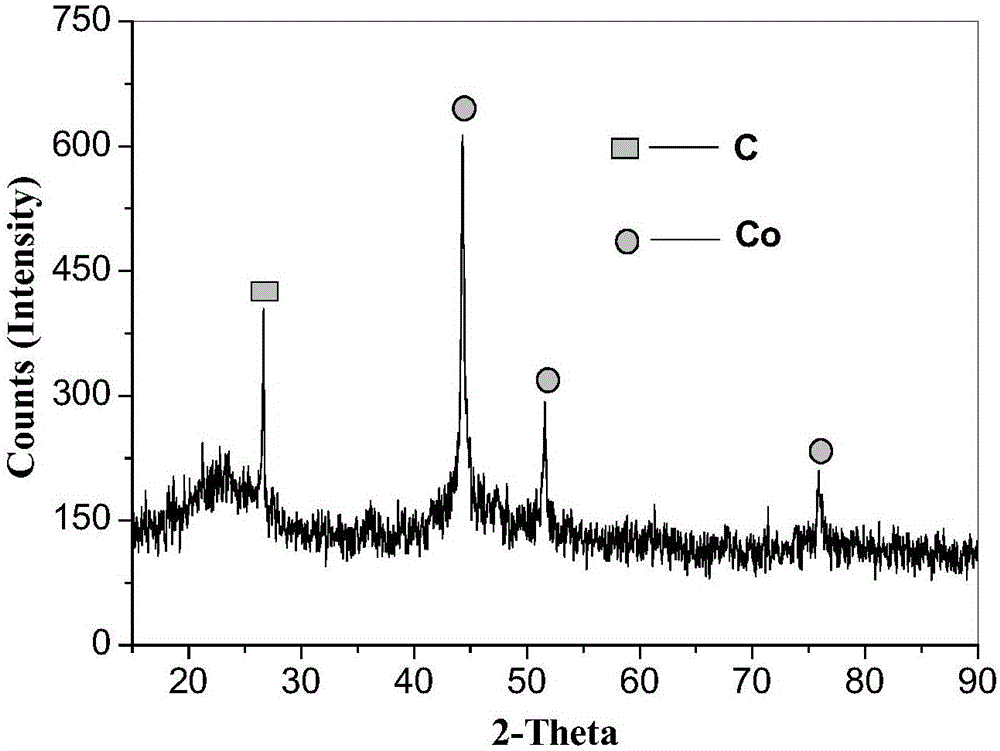

Embodiment 1

[0039] (1) Put porous carbon spheres with a particle size distribution of 0.5-2mm in a nitric acid solution with a mass fraction of 40-60%, the mass of carbon spheres to the volume ratio of nitric acid is 1g: 15-30ml, and then Stir and impregnate in a water bath for 10-12 hours, wash with deionized water repeatedly until neutral, then dry in an oven at 100-110°C for 12-24 hours;

[0040] (2) Take cobalt salt and dissolve it in deionized water to prepare a precursor solution. The mass of cobalt salt and the volume ratio of deionized water are 2-6g: 10-30ml;

[0041] (3) Dip the porous carbon spheres into the above-mentioned precursor solution respectively, stir and impregnate for 12-24 hours, the volume ratio of the mass of the carbon spheres to the precursor solution is 1-3g: 9-20ml;

[0042] (4) The porous carbon spheres are filtered out from the solution, washed with 10-40ml deionized water, and filtered;

[0043] (5) Put the porous carbon spheres obtained in (4) into an ov...

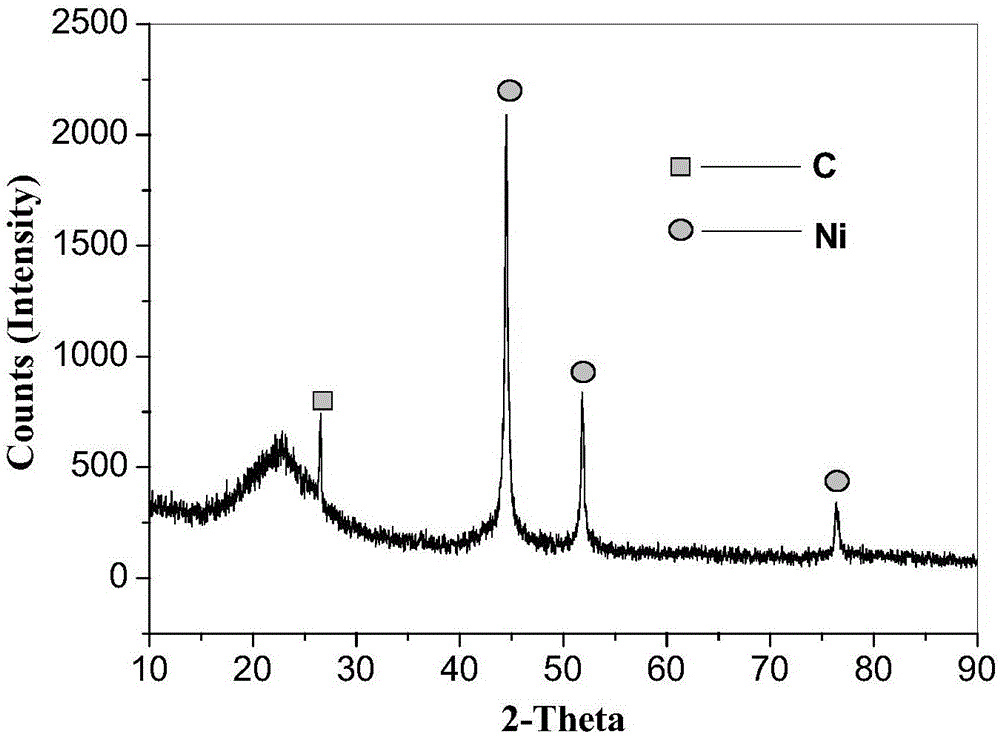

Embodiment 2

[0047] (1) Put porous carbon spheres with a particle size distribution of 0.5-2mm in a nitric acid solution with a mass fraction of 40-60%, the mass of carbon spheres to the volume ratio of nitric acid is 1g: 15-30ml, and then Stir and impregnate in a water bath for 10-12 hours, wash with deionized water repeatedly until neutral, then dry in an oven at 100-110°C for 12-24 hours;

[0048] (2) Take nickel salt and dissolve it in deionized water respectively to prepare a precursor solution. The mass ratio of nickel salt to deionized water is 2-6g: 10-30ml;

[0049] (3) Dip the porous carbon spheres into the above-mentioned precursor solution respectively, stir and impregnate for 12-24 hours, the volume ratio of the mass of the carbon spheres to the precursor solution is 1-3g: 9-20ml;

[0050] (4) The porous carbon spheres are filtered out from the solution, washed with 10-40ml deionized water, and filtered;

[0051] (5) Put the porous carbon spheres obtained in (4) into an oven ...

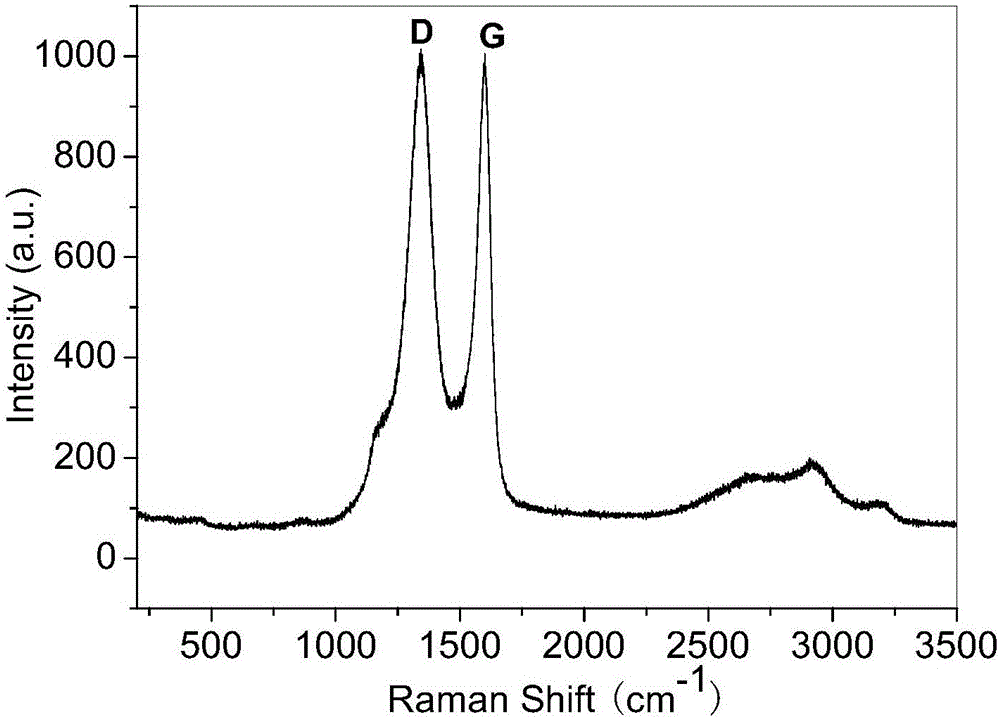

Embodiment 3

[0055] (1) Put porous carbon spheres with a particle size distribution of 0.5-2mm in a nitric acid solution with a mass fraction of 40-60%, the mass of carbon spheres to the volume ratio of nitric acid is 1g: 15-30ml, and then Stir and impregnate in a water bath for 10-12 hours, wash with deionized water repeatedly until neutral, then dry in an oven at 100-110°C for 12-24 hours;

[0056] (2) Take cobalt salt and dissolve it in deionized water to prepare a precursor solution. The mass of cobalt salt and the volume ratio of deionized water are 2-6g: 10-30ml;

[0057] (3) Dip the porous carbon spheres into the above-mentioned precursor solution respectively, stir and impregnate for 12-24 hours, the volume ratio of the mass of the carbon spheres to the precursor solution is 1-3g: 9-20ml;

[0058] (4) The porous carbon spheres are filtered out from the solution, washed with 10-40ml deionized water, and filtered;

[0059] (5) Put the porous carbon spheres obtained in (4) into an ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com