High-power lithium iron phosphate positive pole material and manufacturing method thereof

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of irregular material morphology, achieve the effect of improving rate performance, increasing the degree of graphitization, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Select battery-grade raw material Li 2 CO 3 , FeC 2 o 4 2H 2 O, NH 4 h 2 PO 4 , the molar ratio is according to Li:Fe:P=1.03:1:1, and all the weighed materials are added to the basket grinder filled with ethanol, the grinding time is 2h, and the temperature of the ground slurry is 90°C Dry for 4 hours, because it will agglomerate after drying, so break it with a crusher and put it in a crucible. Using nitrogen as a protective gas, put it into a tube furnace at 650 ° C for 7 hours to obtain uncoated LiFePO 4 sample.

[0025] 2) Take 158g uncoated LiFePO 4 For the sample, use anhydrous ethanol as a solvent, add 10g of fructose and 2.25g of ferrocene alcohol solution, grind, wait for complete drying (60°C, 3 hours treatment), and crush with a universal crusher.

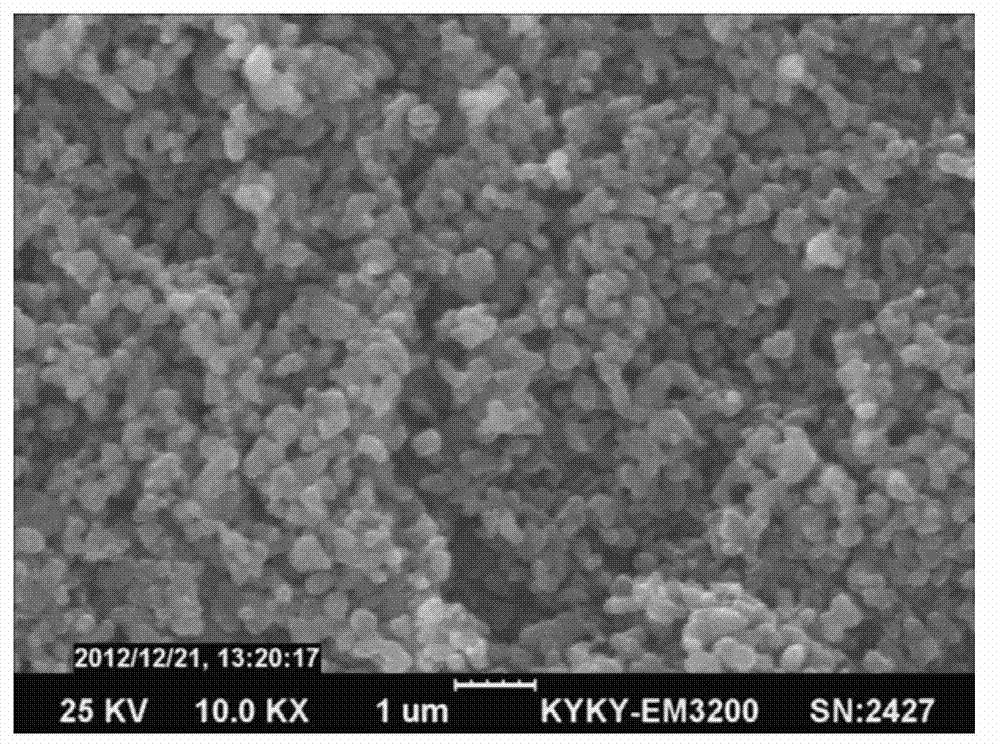

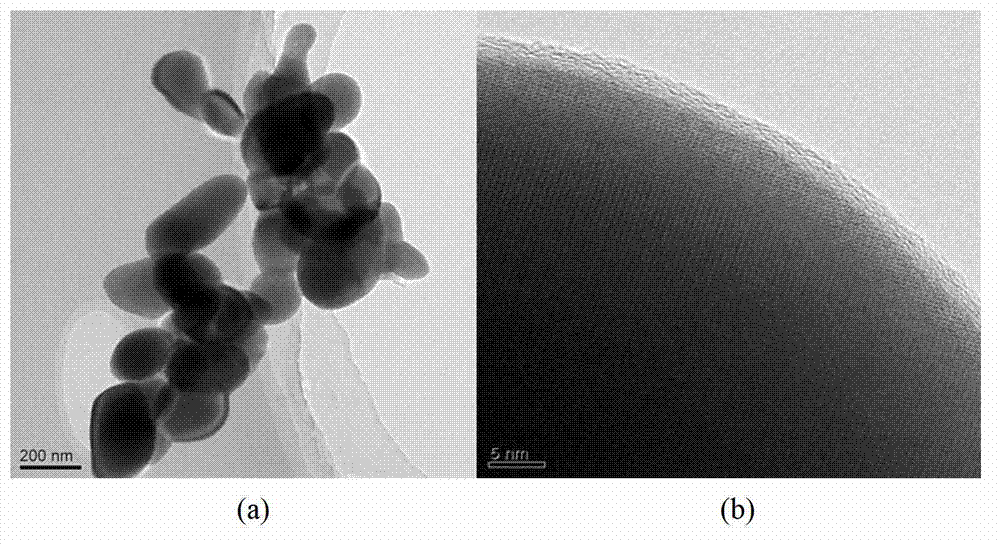

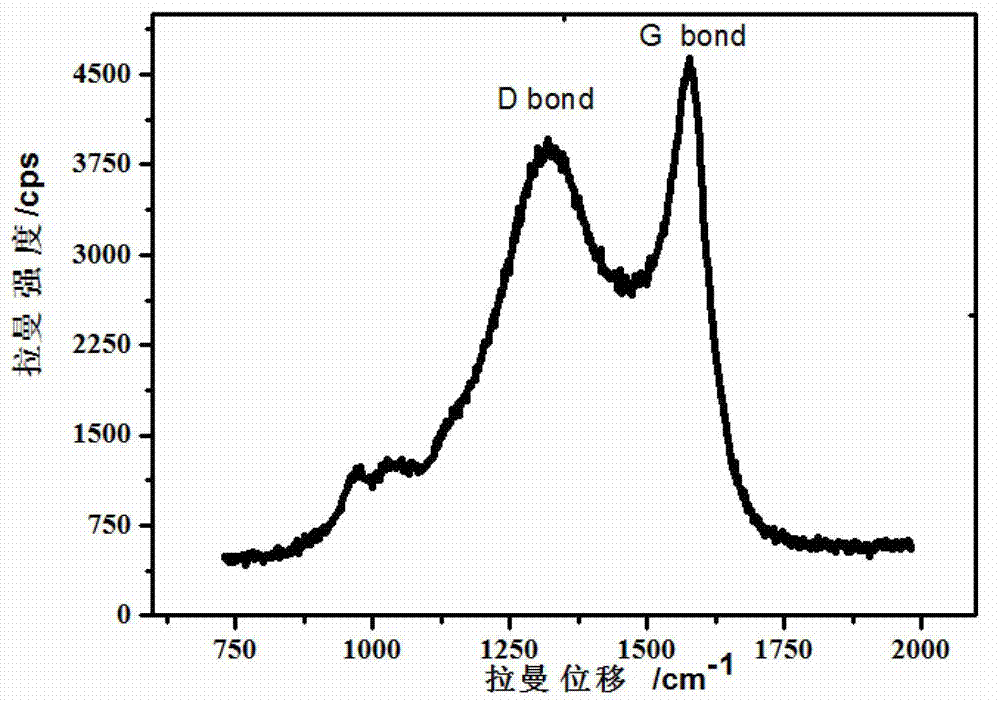

[0026] 3) Using Ar gas as a protective gas, the temperature was raised to 650 degrees, and the above mixture was kept at a constant temperature in a tube furnace for 10 hours, and then sintered to obt...

Embodiment 2

[0032] 1) Select battery grade raw materials LiOH, Fe 2 o 3 , (NH 4 ) 2 HPO 4 , the molar ratio is according to Li:Fe:P=1.2:1:1, and all the weighed materials are added to the basket mill filled with deionized water. The grinding time is 2h, and the ground slurry is placed at a temperature of Dry it at 150°C for 1 hour, crush it with a crusher, and put it in a crucible. Using argon as a protective gas, put it into a tube furnace for 5 hours at 750 ° C to pre-fire to obtain uncoated LiFePO 4 sample.

[0033] 2) Take 317g uncoated LiFePO 4 For the sample, use anhydrous ethanol as a solvent, add 21g rock sugar and 6.34g cobalt dicene in acetone solution, grind, wait for complete drying (100°C, 1 hour treatment), and crush it with a universal crusher.

[0034] 3) Using nitrogen as the protective gas, the temperature was raised to 600 degrees, and the above mixture was kept at a constant temperature in a tube furnace for 10 hours, and then sintered to obtain LiFePO 4 / C com...

Embodiment 3

[0036] 1) Select battery-grade raw material LiCH 3 COO, Fe(CH 3 COO) 2 、H 3 PO 4 , the molar ratio is according to Li:Fe:P=1:1:1.05, and all the weighed materials are added to the basket grinder filled with acetone, the grinding time is 2h, and the temperature of the ground slurry is 110°C Dry it for 5 hours, crush it with a crusher, and put it in a crucible. Using nitrogen as a protective gas, put it into a tube furnace at 500 ° C for 10 hours to obtain uncoated LiFePO 4 sample.

[0037] 2) Take 1581g uncoated LiFePO 4 For the sample, use anhydrous ethanol as a solvent, add 102g of citric acid and 23g of titanocene alcohol solution, grind, wait for complete drying (140°C, 2.5 hours treatment), and crush with a universal crusher.

[0038] 3) Using argon as the protective gas, the temperature rises to 750 degrees, and the above mixture is kept at a constant temperature in a tube furnace for 5 hours, and then sintered to obtain LiFePO 4 / C composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com