Micro-wave preparation method for biomass-based graphitized carbon and carbon-carbon composite material

A technology of graphitizing carbon and biomass, applied in the field of graphitic carbon, to achieve the effects of high degree of graphitization, low energy consumption, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

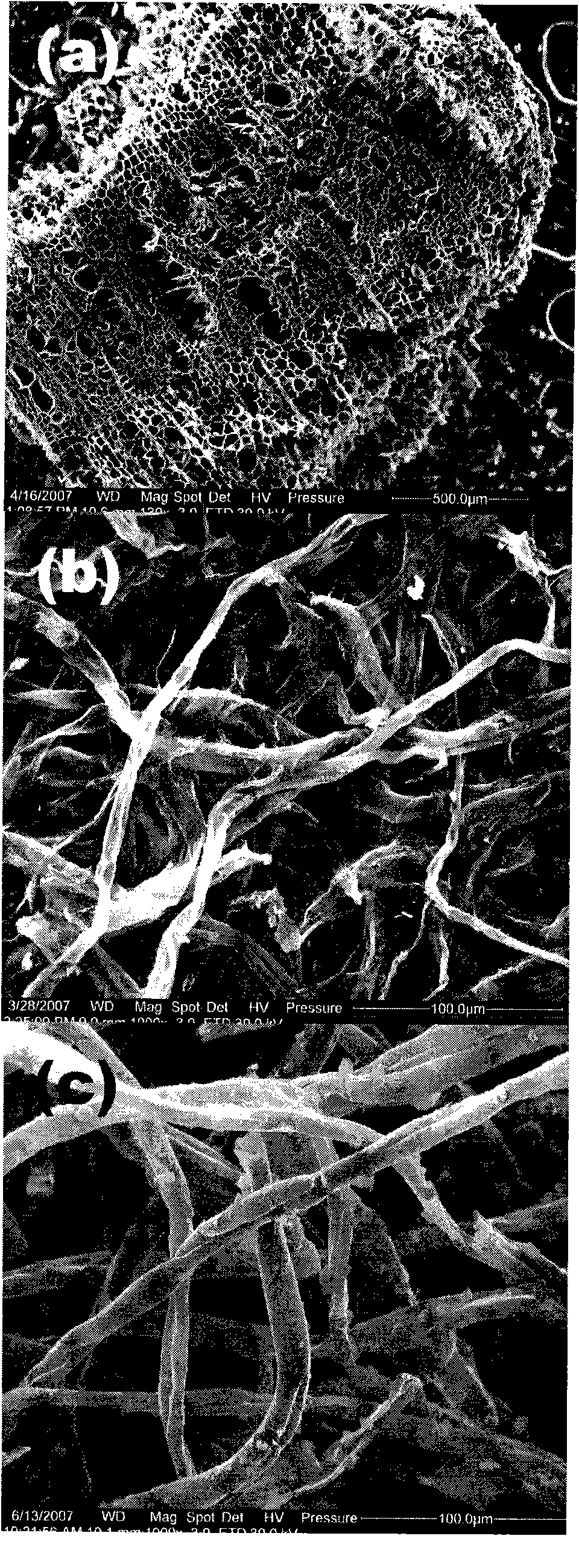

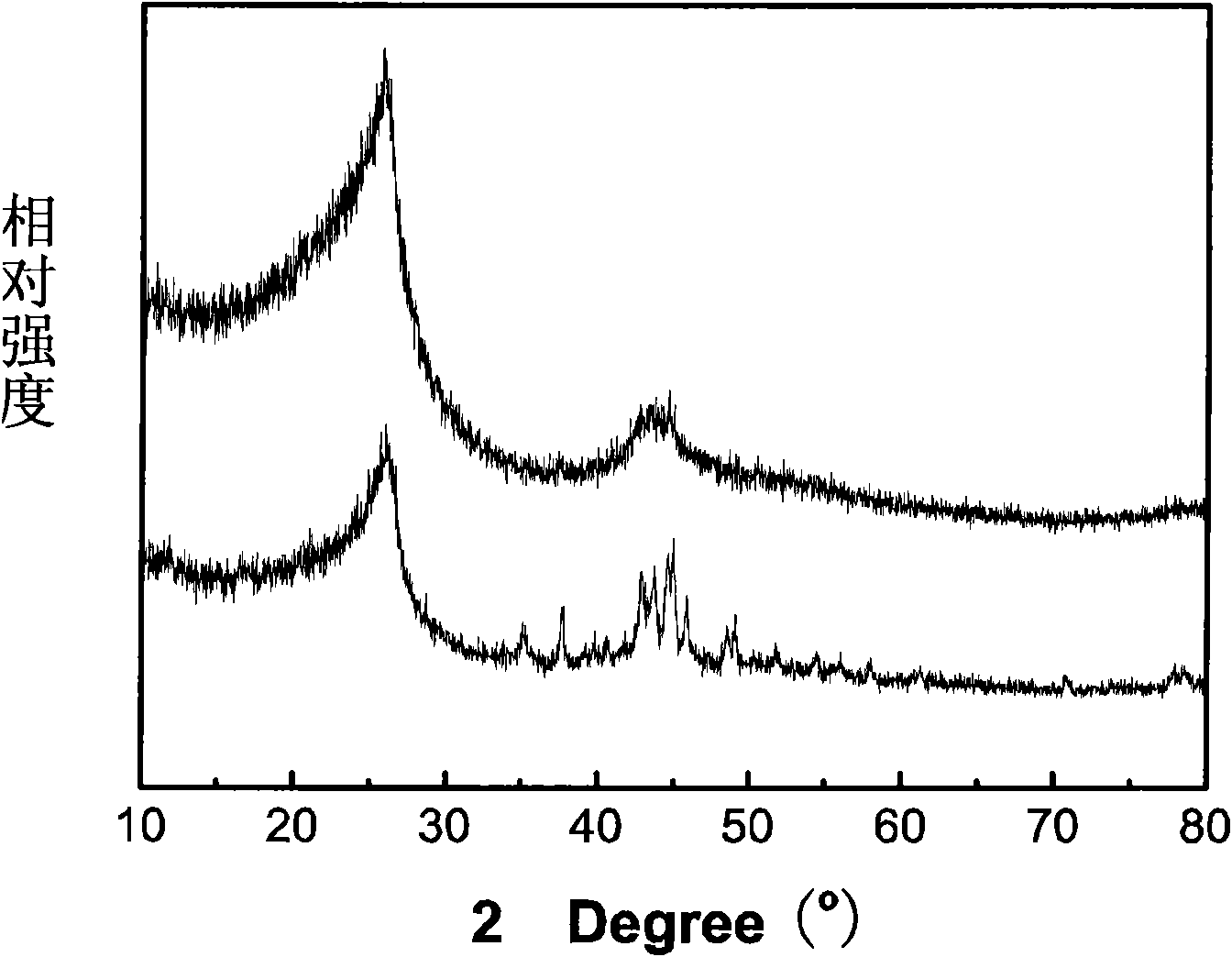

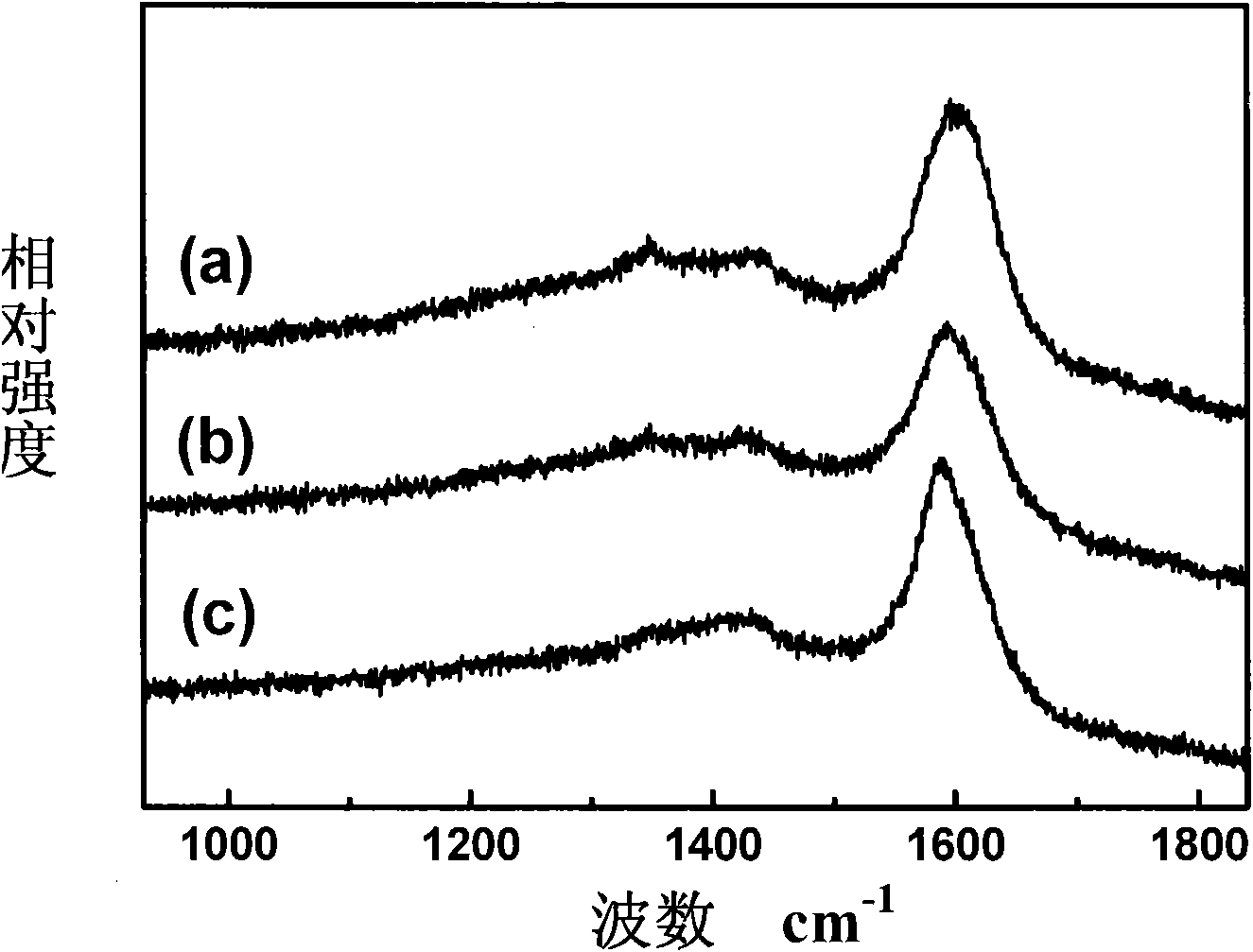

Embodiment 1

[0038] Dilute 0.324 g filter paper in 0.1 g / ml FeCl 3 Soak in solution (15mL) for 0.5 hour, take out and dry. impregnated with FeCl 3 The filter paper was suspended in a closed container filled with pyrrole, and subjected to vapor phase polymerization at 30° C. for 7 days to obtain a Fe / PPy / filter paper composite (mass ratio 2.5 / 2.5 / 100). The Fe / PPy / filter paper composite was transferred into a microwave reactor, and treated with microwave for 5 minutes, and the microwave power was controlled at 1000W. The Fe / PPy / filter paper composite continued to maintain a hot state during the reaction process. After the reaction, the product was cooled to room temperature and treated with an acid with a concentration of 2mol / L to remove the generated iron carbide, filtered and dried to obtain a high specific Surface area of graphitized carbon nanostructure material with a pore volume of 0.33 cm 3 / g, the specific surface area is 293.2m2 / g. SEM results showed that the macroscopic and...

Embodiment 2

[0040] Add 0.5 g of wood to 0.1 g / ml FeCl 3 Soak in solution (15mL) for 3 hours, take out and dry. The dried impregnated with FeCl 3 The wood was suspended in a closed container filled with pyrrole, and subjected to vapor phase polymerization at 50° C. for 14 days to obtain Fe / PPy / wood composite (mass ratio 14.5 / 14.5 / 100). The Fe / PPy / wood composite was transferred to a microwave reactor, and treated with microwave for 5 minutes, and the power of the microwave was controlled at 1000W. The Fe / PPy / wood composite continued to maintain a hot state during the reaction. After the reaction, the product was cooled to room temperature, and after being treated with an acid with a concentration of 4mol / L, the generated iron carbide was removed, filtered, and dried to obtain a high specific graphitized carbon nanostructure material with a surface area of 0.24 cm pore volume 3 / g, the specific surface area is 350.9m 2 / g.

Embodiment 3

[0042] Add 0.5 g of cotton to 0.1 g / ml FeCl 3 Soak in the solution (15mL) for 1.5 hours, take it out and dry it. The dried impregnated with FeCl 3 The cotton was suspended in an airtight container filled with pyrrole, and subjected to vapor phase polymerization at 30° C. for 9 days to obtain Fe / PPy / cotton composite (mass ratio 9.5 / 9.5 / 100). The Fe / PPy / cotton composite was transferred to a microwave reactor, and treated with microwave for 5 minutes, and the microwave power was controlled at 700W. The Fe / PPy / filter paper composite continued to maintain a hot state during the reaction process. After the reaction, the product was cooled to room temperature and treated with an acid with a concentration of 2mol / L to remove the generated iron carbide, filtered and dried to obtain a high specific graphitized carbon nanostructure material with a surface area of 0.26 cm pore volume 3 / g, the specific surface area is 431.3m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com