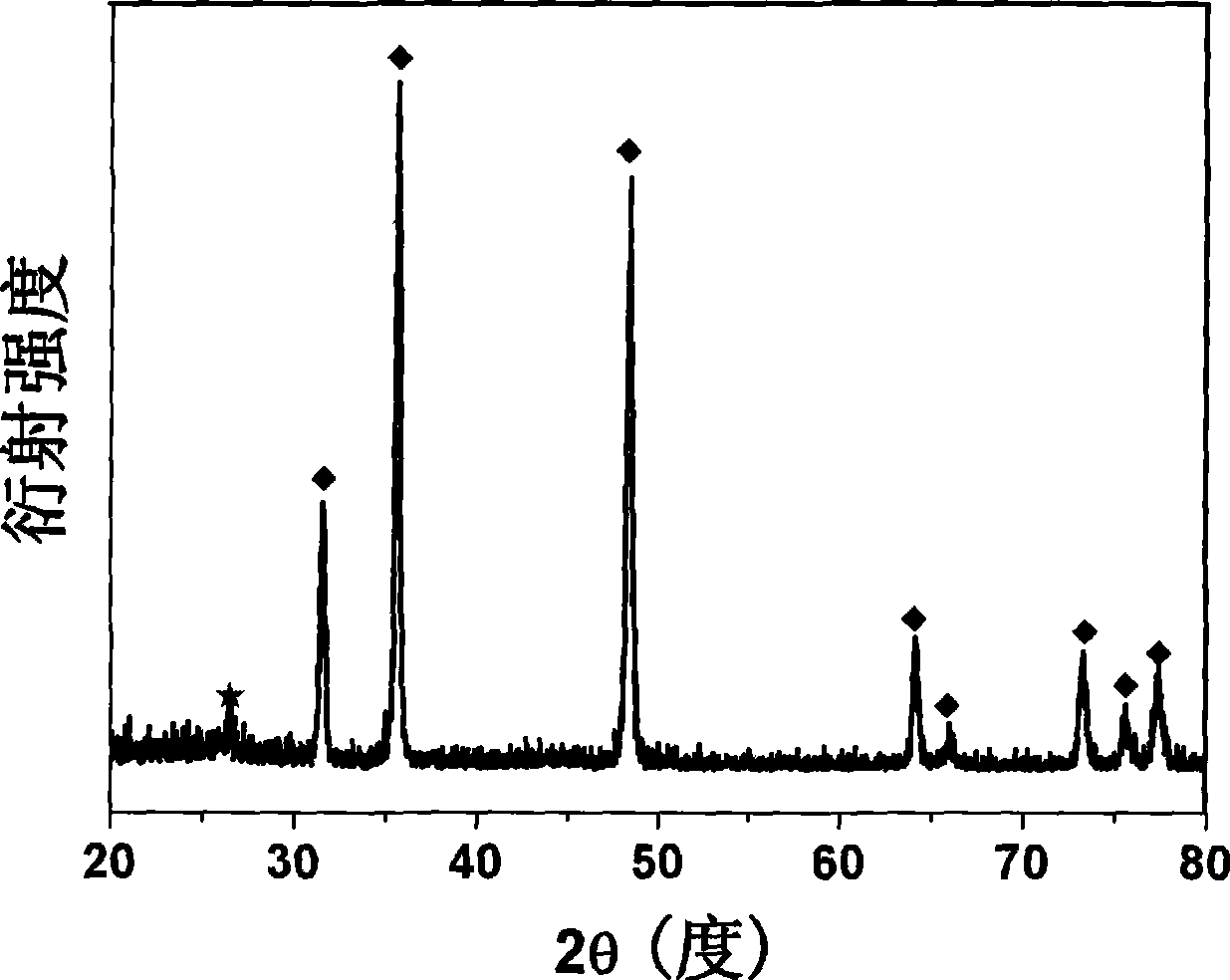

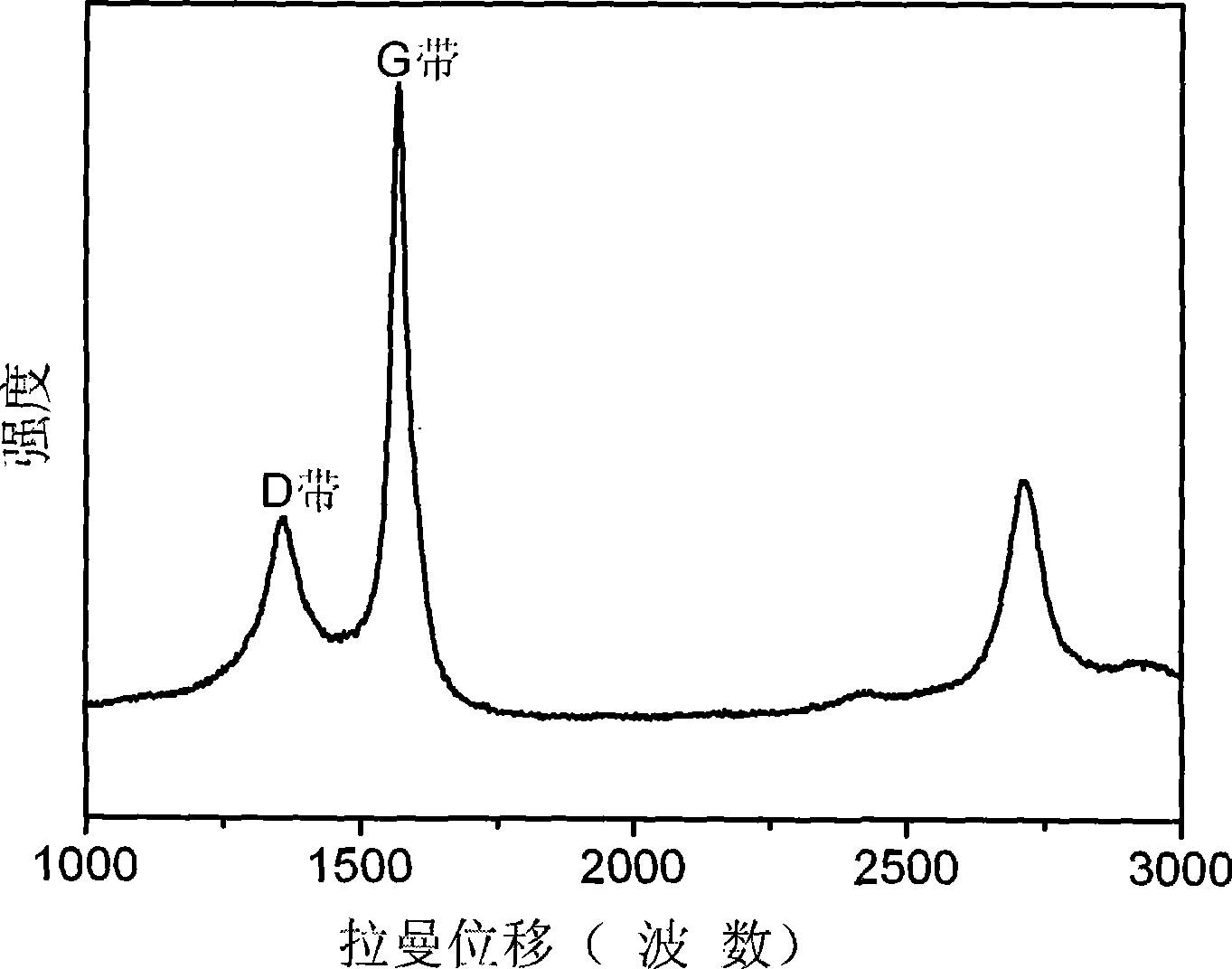

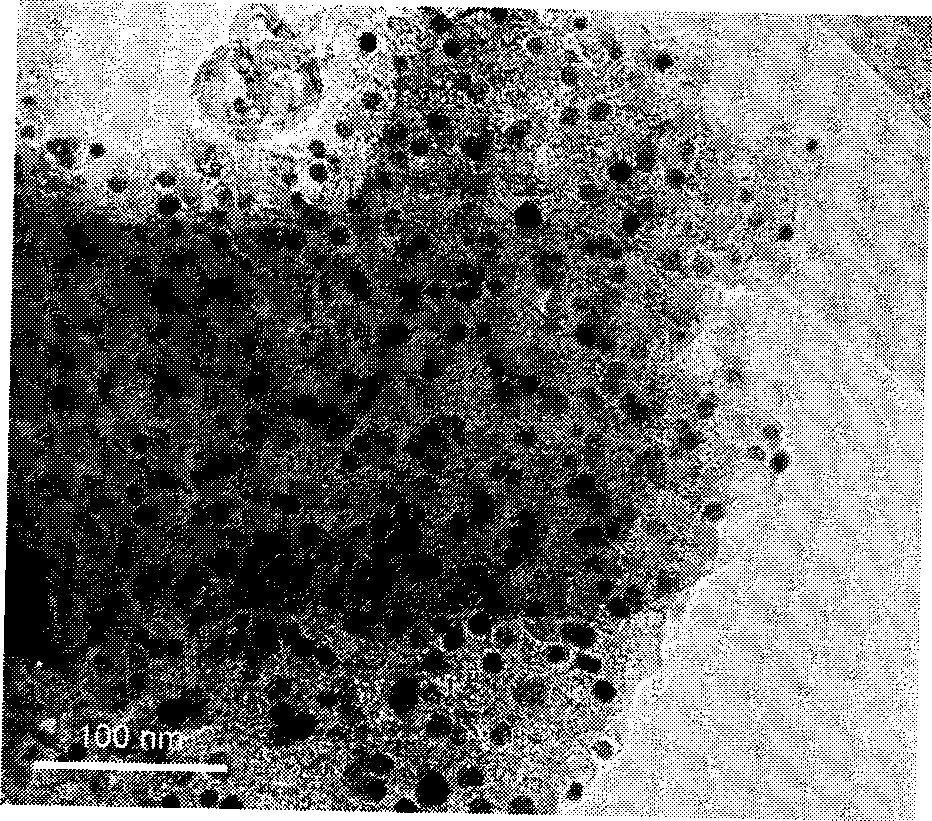

In-situ synchronous synthesizing method of tungsten carbide/graphitic carbon nano complexes

A nano-composite, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problem of uneven distribution of tungsten carbide, and achieve cheap carbon source, lower production cost, and less environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: The method for in-situ synchronous synthesis of tungsten carbide / graphite carbon nanocomposites in this embodiment is completed by the following steps: 1. Pretreating the carbon source for 10 minutes to 8 hours (the purpose is to activate the carbon source); 2. Dissolve the graphitization catalyst and tungsten source in the solvent, wherein the concentration of the graphitization catalyst is 0.01-0.3mol / L, the concentration of the tungsten source is 0.01-0.3mol / L, then add the pretreated carbon source, and then disperse evenly , the mass ratio of the carbon source to the graphitization catalyst is 0.01-1:1; 3. Pre-carbonize the mixture of step 2 for 1-12 hours in an atmosphere of air or oxygen at a pre-carbonization temperature of 90-450° C.; The heating rate of 25°C / min is raised from room temperature to the heat treatment temperature of 500-1600°C, and then the product of step 3 is heat-treated for 10min-10h, the flow rate of the heat treatment a...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pretreatment time in step 1 is 30 minutes to 6 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 in that: the pretreatment time in step 1 is 1 to 4 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com