Preparation method of ordered mesoporous carbon material with high specific surface area by using metal organic skeleton

A technology of metal-organic framework and high specific surface area, which is applied in the preparation of solid mesoporous carbon materials and the preparation of ordered mesoporous carbon materials with high specific surface area, which can solve the problems of limited selection of precursor molecules and achieve low cost and mild conditions , the effect of developed porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

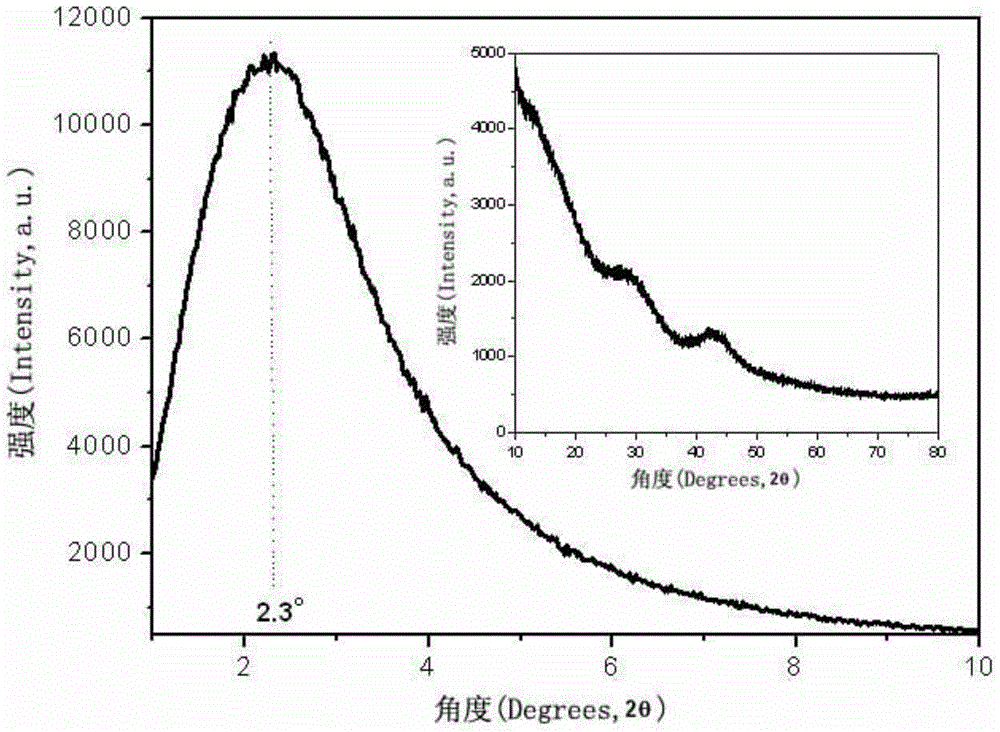

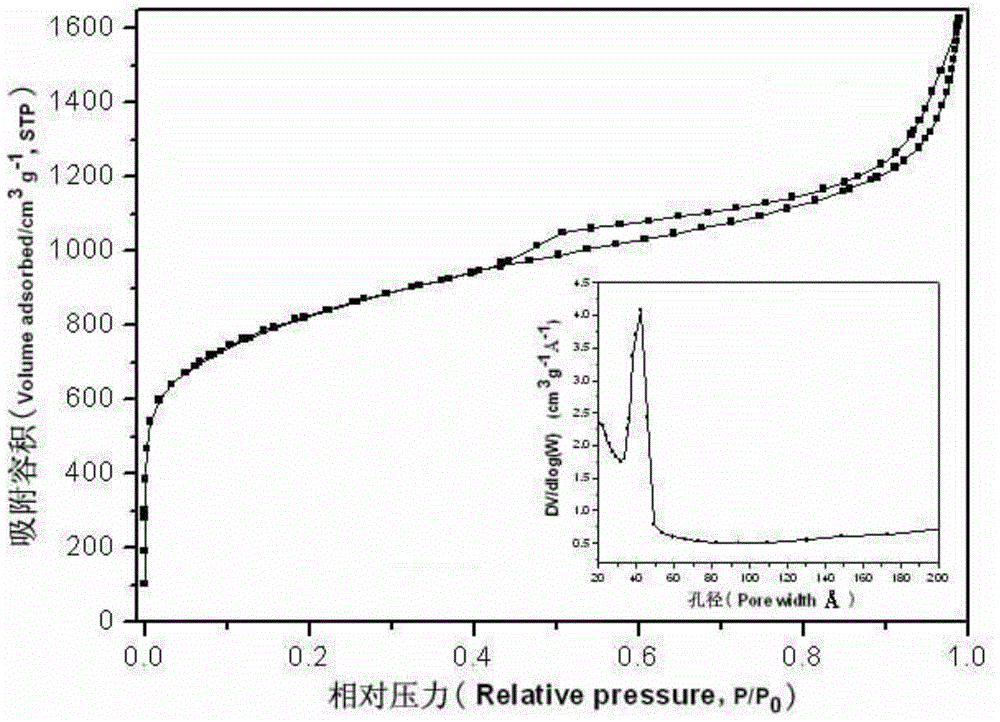

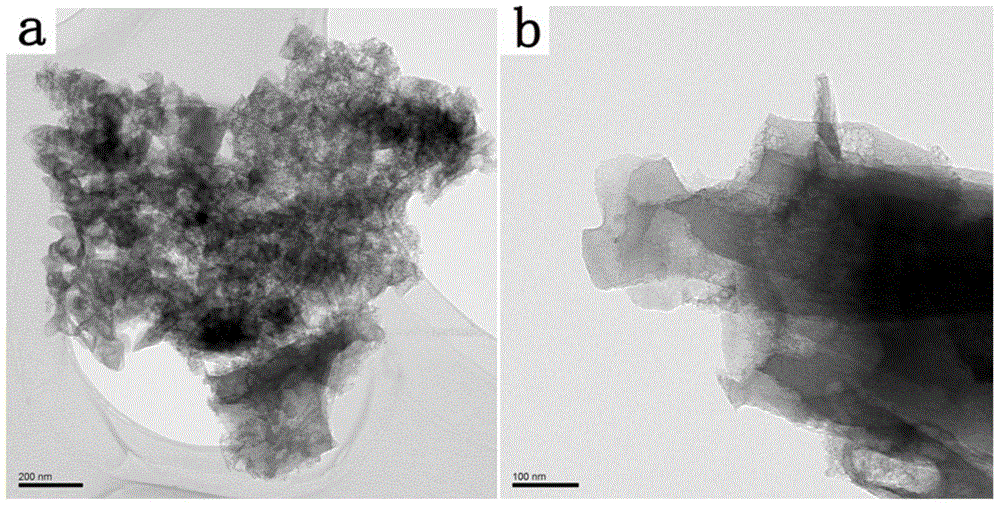

[0024] Weigh 6.0g Zn(NO 3 ) 2 ·6H 2 Dissolve O (20mmol) and 1.67g terephthalic acid (10mmol) in 50ml DMF, stir to form a homogeneous solution, add 11.0ml triethylamine dropwise, then stir at room temperature for 1h, and slowly wash the formed solid with 25-50ml DMF , then with about 75ml of CHCl 3 Exchange for 24h, and finally vacuum dry at 80°C for 5h. then in N 2 In the atmosphere, the temperature was raised to 950°C at a rate of 5°C / min, and then kept at this temperature for 2 hours to obtain a mesoporous carbon material with a specific surface area of 2726m 2 / g, the pore diameter is 4.2nm, and the pore volume is 2.10cm 3 / g.

Embodiment 2

[0026] Weigh 5mmol of zinc acetate dihydrate and 10mmol of terephthalic acid and dissolve them in 50ml of DEF, stir to form a homogeneous solution, add 2.7ml of triethylamine dropwise, then stir at room temperature for 0.5h, and slowly wash the formed solid with 25-50ml of DEF , and then with about 65ml of CHCl 3 Exchange for 20h, and finally vacuum dry at 80°C for 4h. then in N 2 In the atmosphere, the temperature was raised to 930° C. at a rate of 1° C. / min, and then kept at this temperature for 24 hours to obtain a mesoporous carbon material.

Embodiment 3

[0028] Weigh 100mmol of zinc chloride and 10mmol of terephthalic acid and dissolve them in 200ml of DMAC, stir to form a homogeneous solution, add 55.0ml of triethylamine dropwise, then stir at room temperature for 12h, and slowly wash the formed solid with 100-200ml of DMAC, then With about 90ml of CHCl 3 Exchange for 30h, and finally vacuum dry at 80°C for 6h. then in N 2 In the atmosphere, the temperature was raised to 980° C. at a rate of 15° C. / min, and then kept at this temperature for 1 hour to obtain a mesoporous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com