Method for preparing porous boron-carbon-nitrogen nanosheets through freeze drying

A technology of drying treatment and nanosheets, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of not being able to effectively expand the specific surface area of BCN nanosheets, and achieve easy monitoring and control, and easy Reaction mechanism, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.62g of boric acid, 1.80g of glucose, and 0.60g of urea. The molar ratio of the three is 1:1:1, and the molar percentages are the same. Then put the three substances in a beaker, add 54mL of water and stir to dissolve, the molar ratio of water to raw material mixture is 100:1.

[0026] (2) Seal the beaker with an air-permeable film, put it into the refrigerator to condense and solidify, and then carry out freeze-drying treatment.

[0027] (3) Put the freeze-dried powder into a ceramic boat and place it in a tube furnace. Under the protection of a nitrogen atmosphere, the temperature was raised to 1000°C at a rate of 10°C / min, and kept for 5 hours.

[0028] (4) Put the calcined reaction product into a ball mill and mill it for 4 hours.

[0029] (5) After the product was cooled to room temperature, it was washed with deionized water until neutral to obtain Porous BCN nanosheets.

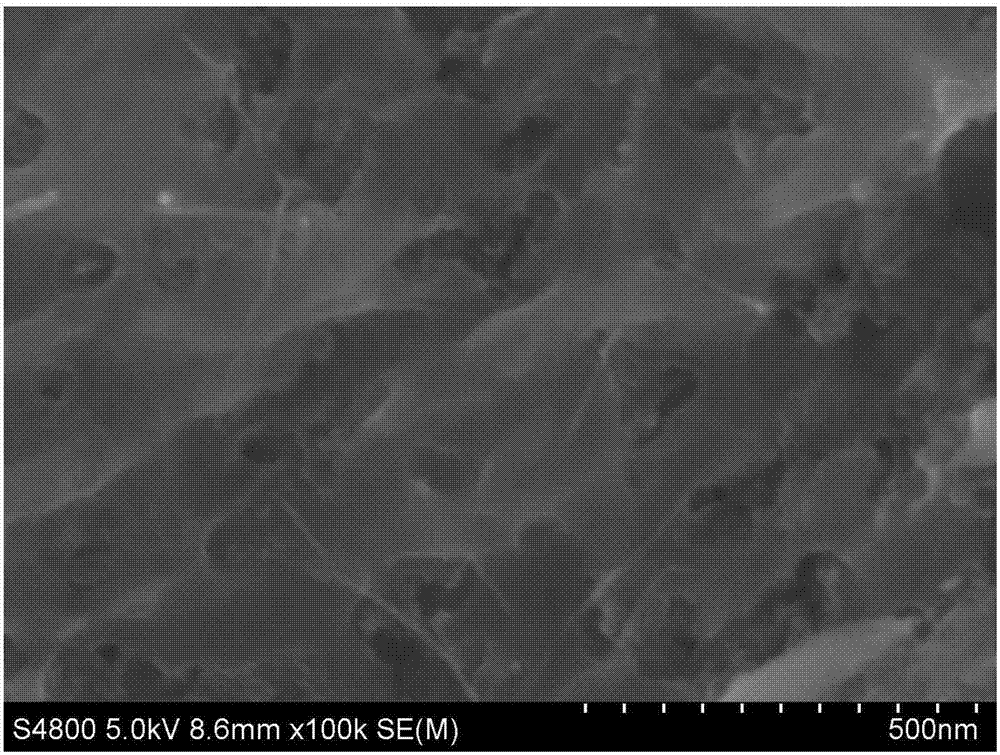

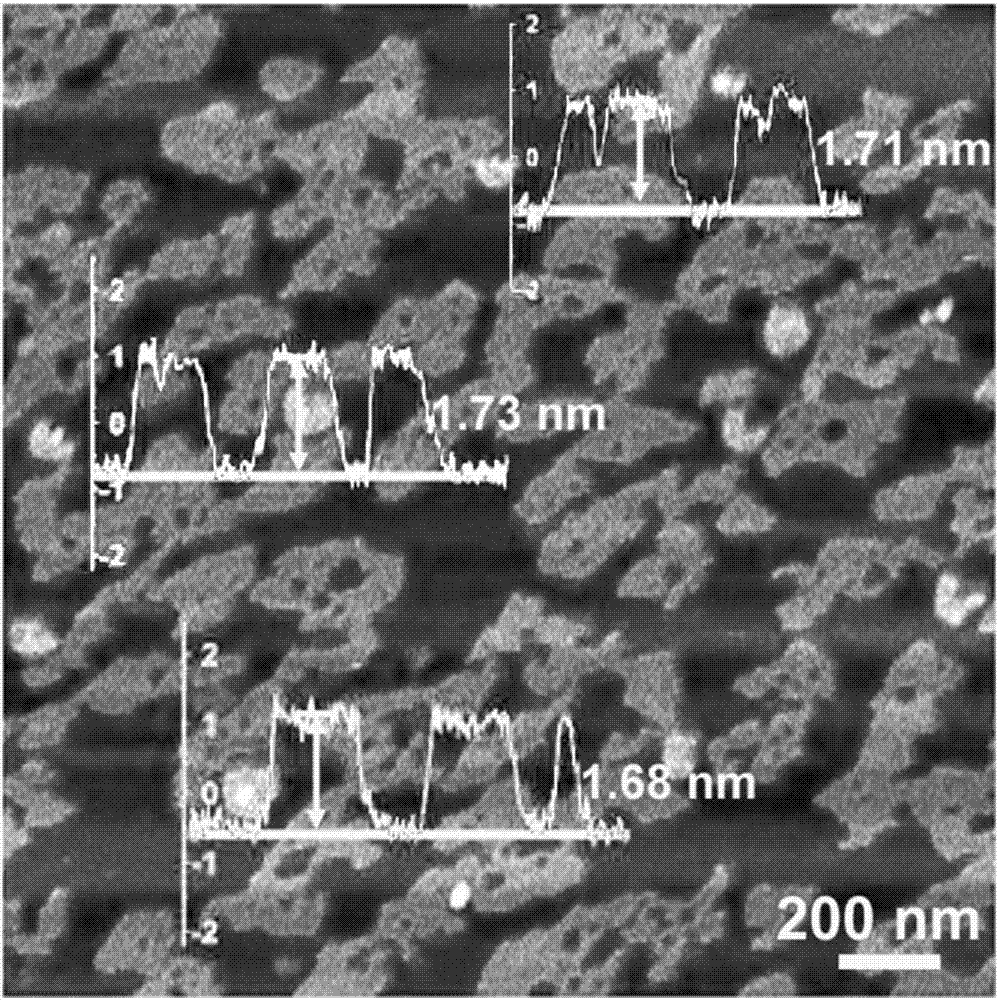

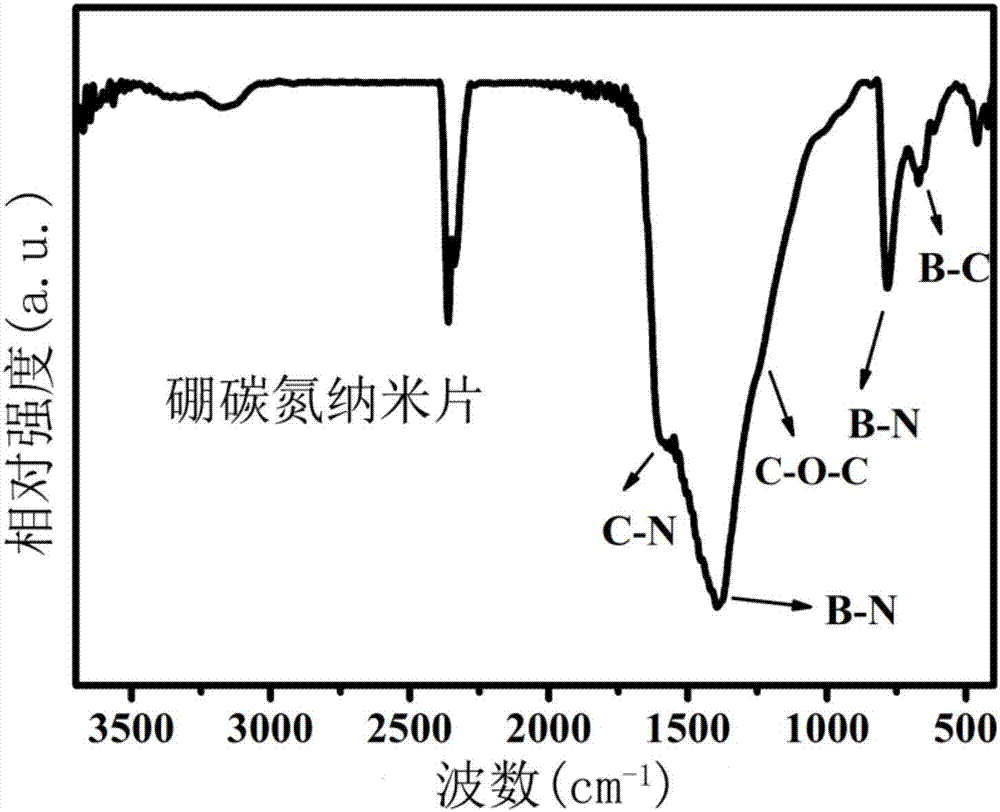

[0030] The scanning electron microscope picture of the Porous BCN nanosheet pr...

Embodiment 2

[0032] As described in Example 1, the difference is that the boron source is boron oxide in step (1):

[0033] Weigh 0.69g of boron oxide, 1.80g of glucose, and 0.60g of urea, and the molar ratio of the three is 1:1:1.

Embodiment 3

[0035] As described in Example 1, the difference is that the boron source in step (1) is ammonium borate: weigh 2.28 g of ammonium borate, 1.80 g of glucose, and 0.60 g of urea, and the molar ratio of the three is 1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com