Preparation method for self-assembly carbonitride nanotube and nanotube prepared by using same

A technology of carbon nitride and self-assembly, applied in the direction of nanotechnology, nitrogen and non-metallic compounds, etc., can solve the problems of binary compound nanotube synthesis limitations, few nanotube synthesis methods, and high difficulty, achieving great application potential, The effect of increased conductivity and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Melamine is dissolved in ethylene glycol to obtain a saturated solution;

[0027] (2) Slowly add 0.12 mol / L nitric acid solution into the above-mentioned saturated solution and stir slowly until a large amount of precipitation occurs; the volume ratio of adding nitric acid solution and ethylene glycol solution is 3:1.

[0028] (3) Centrifuge the reaction product to obtain solid powder, then wash with distilled ethanol, and then dry at 60° C. for 5 hours to obtain the self-assembled carbon nitride nanotube precursor; the drying time can be 4 or 6 hours.

[0029] (4) The obtained self-assembled carbon nitride nanotube precursor is placed in a muffle furnace and calcined at a temperature of 350° C. for 1 hour to obtain the self-assembled carbon nitride nanotube.

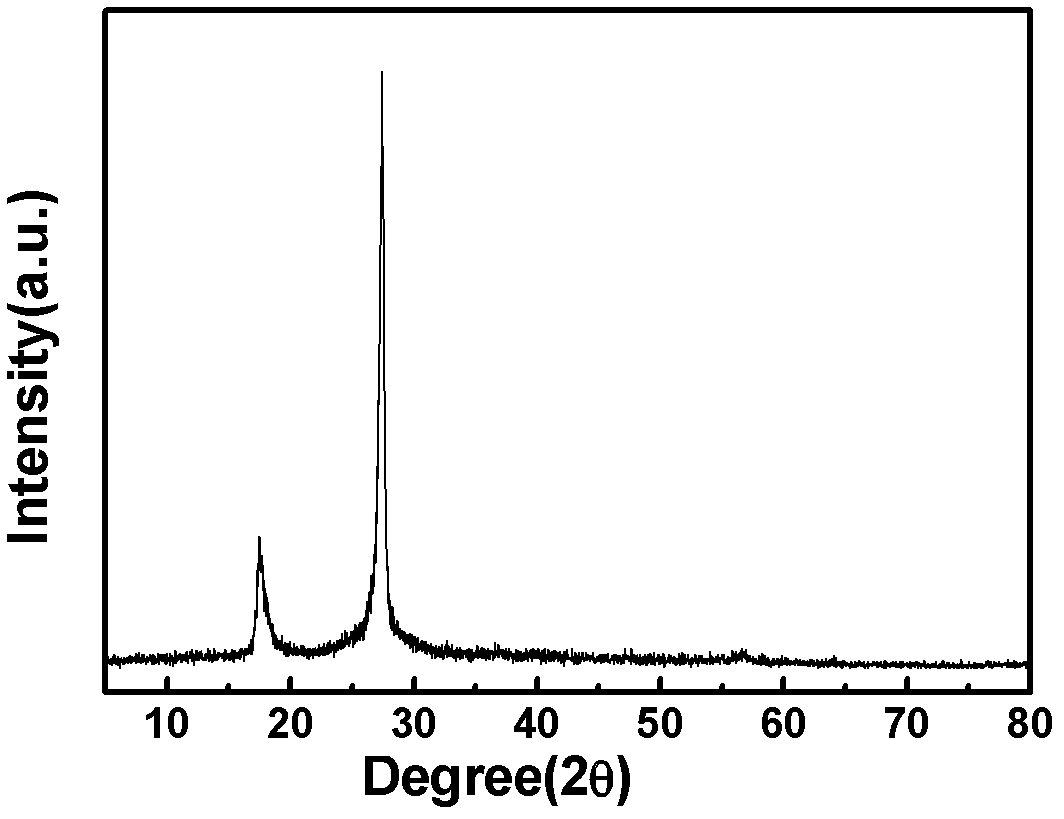

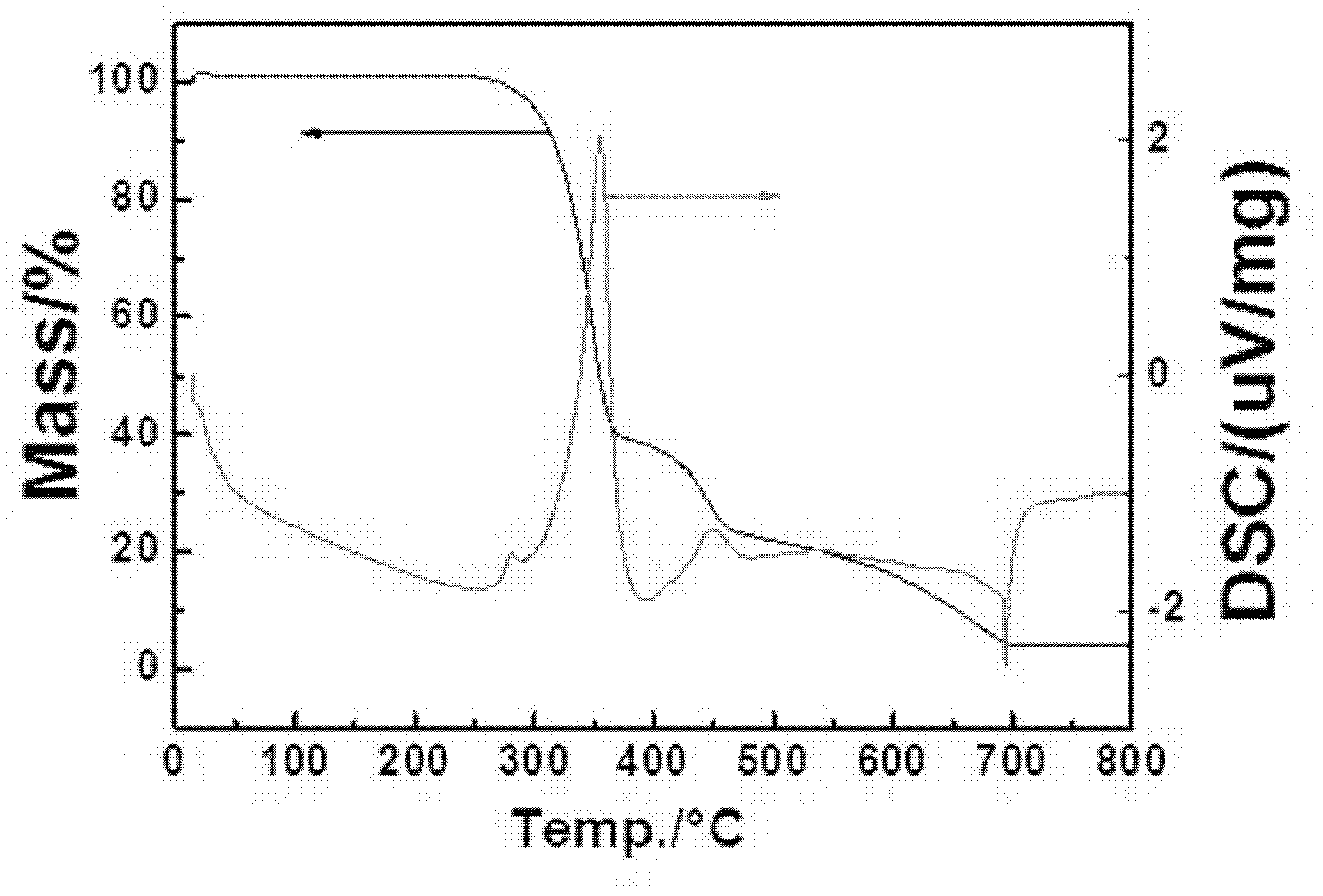

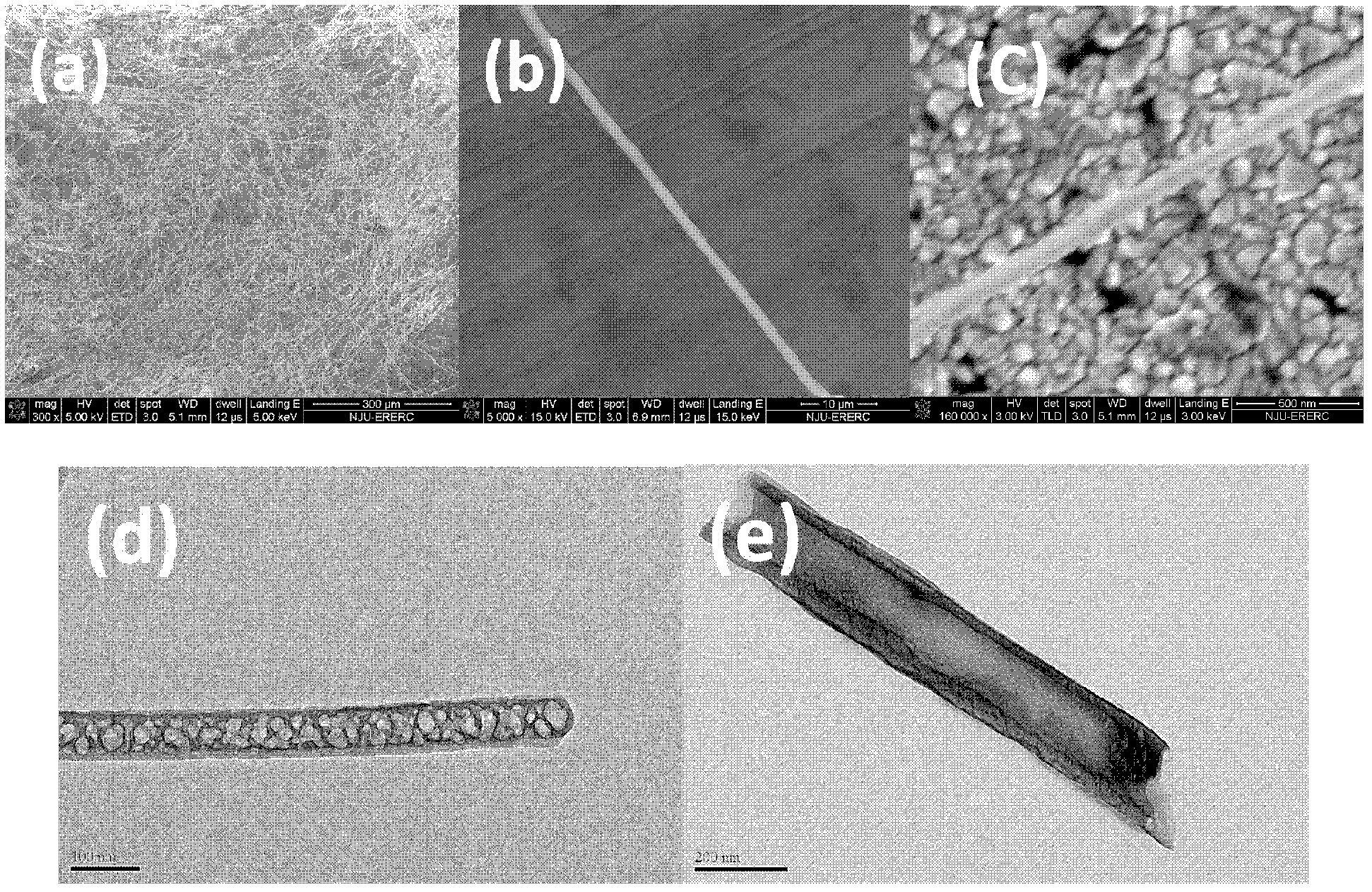

[0030] The products are analyzed by X-ray line diffraction (XRD), thermogravimetry (TG), differential thermal analysis (DSC), fluorescence spectroscopy, scanning electron microscopy, transmission electron mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com