Complete solid-phase synthesis method for liraglutide

A solid-phase synthesis method, the technology of liraglutide, applied in the field of all-solid-phase synthesis of liraglutide, can solve the problems of large-scale production risk, increase the difficulty of purification, unfavorable industrial production, etc., and achieve low production cost , easy central control, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

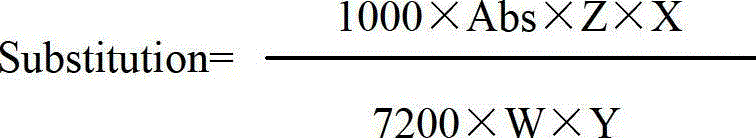

Image

Examples

Embodiment

[0025] Taking 1g of 2-Cl-Trt resin as an example below, the operation process of the present invention will be described in detail.

[0026] 1. Experimental raw materials

[0027] 2-Cl-Trt-resin, Fmoc-His(Trt)-OH, Fmoc-Asp(OtBu)-OH,

[0028] Fmoc-Arg(pbf)-OH, Fmoc-Leu-OH, Fmoc-Gly-OH, Fmoc-Tyr(tBu)-OH,

[0029] Fmoc-Ser(tBu)-OH, Fmoc-Ala-OH, Fmoc-Phe-OH, Fmoc-ValOH, Fmoc-Trp(Boc)OH,

[0030] Fmoc-Glu(OtBu)-OH, Fmoc-Gly-OH, Fmoc-Thr(tBu)rOH, Fmoc-Asp(OtBu)-OH,

[0031] Fmoc-Gln(Trt)-OH, Fmoc-Lys(Dde)-OH, Fmoc-Ile-OH, palmitic acid.

[0032] 2. Experimental reagents

[0033] N,N-Dimethylformamide (DMF), Dichloromethane (DCM), N-Hydroxybenzotriazole (HOBT), Benzotriazole-N,N,N',N'-Tetramethyl Urea hexafluorophosphate (HBTU), piperidine, dichloromethane (DIC), anhydrous ether, diisopropylethylamine (DIEA), acetic anhydride, Boc anhydride, hydrazine hydrate, trifluoroacetic acid (TFA), 1 , 2-ethanedithiol (EDT), thioanisole, phenol, ninhydrin (5g / 100ml), phenol (20g / 150ml), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com