Hydro-thermal preparation method for novel near infrared water-soluble copper-indium-sulfur three-element quantum dots

A ternary quantum dot, copper indium sulfide technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as inability to be directly applied in the field of biomedicine, difficult to control segmented heating, complicated operation steps, etc. The effect of low equipment requirements and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

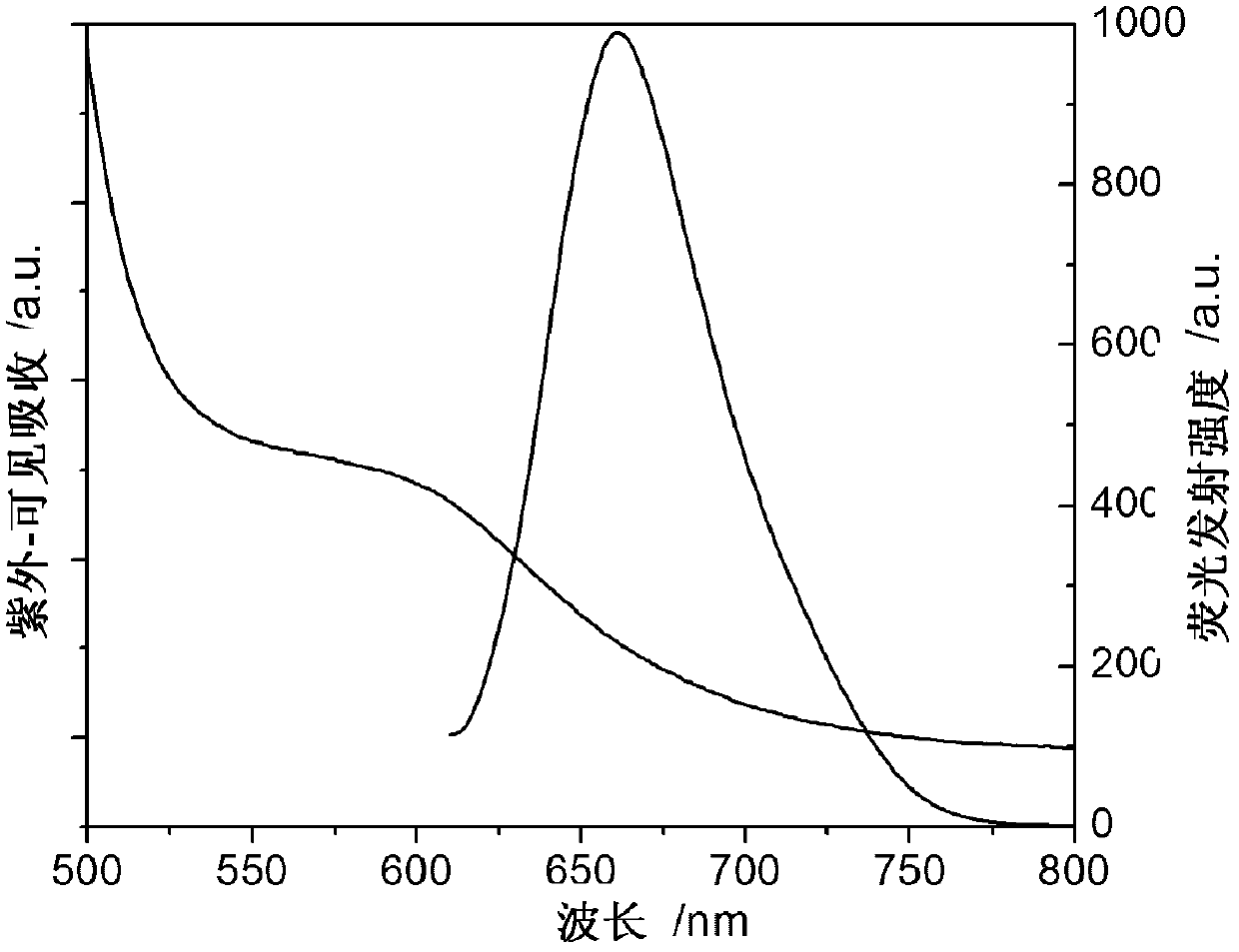

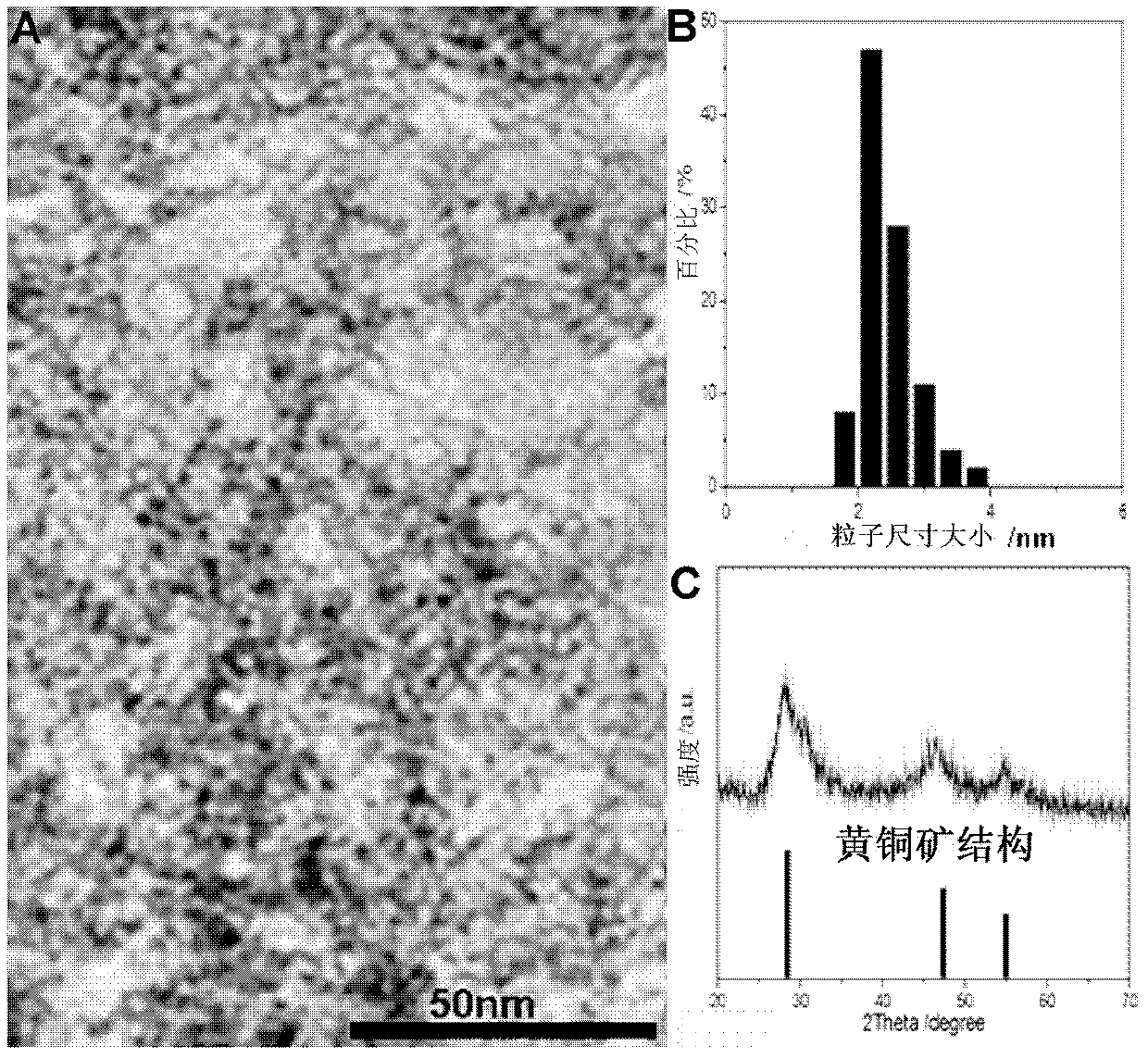

Embodiment 1

[0015] Water-soluble copper indium sulfide (CuInS 2 ) The preparation of quantum dots is divided into the following steps:

[0016] A. Take 0.15mmol of copper dichloride (0.02017 grams) and indium trichloride tetrahydrate (0.04397 grams) and dissolve them together in 10.5ml of water, stir for 15 minutes to obtain Cu containing the same amount of substances 2+ and In 3+ of aqueous solution.

[0017] B. Add 156 μL of 3-mercaptopropionic acid to the above solution at room temperature, and stir for 5 minutes to form small yellow particles, which can be more evenly dispersed in the aqueous solution.

[0018] C. Slowly add 2mol / L NaOH solution to the above-obtained system to dissolve all the small yellow particles to obtain a transparent solution, and continue to drop NaOH solution to bring the pH value of the reaction system to 11.2, and then stir for 10 minutes. The resulting solution is light Red or colorless transparent solution, indicating Cu 2+ and In 3+ A coordination co...

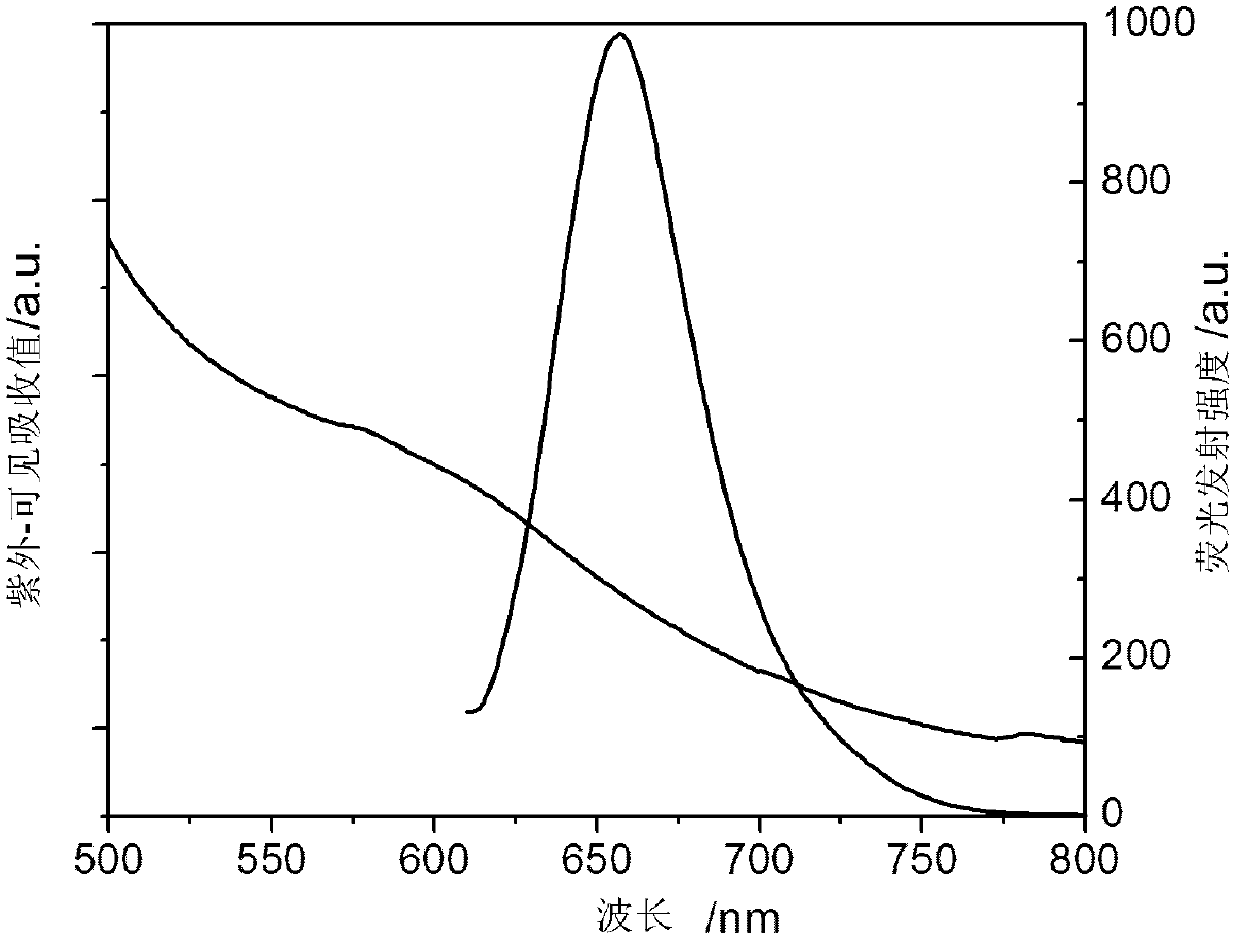

Embodiment 2

[0024] Preparation of 2-mercaptosuccinic acid as copper indium sulfide (CuInS 2 ) quantum dots.

[0025] A. Cu with the same concentration of the substance 2+ and In 3+ The preparation of the aqueous solution, is with embodiment 1 step A.

[0026] B. At room temperature, add 1.8 mmol (about 0.2824 grams) of 2-mercaptosuccinic acid powder to the above solution, and stir for 15 minutes to completely dissolve the mercaptosuccinic acid powder in water.

[0027] C. Add 2mol / L NaOH solution dropwise to the above solution, and adjust the pH value to 11.2. During this process, the solution first gradually changes from light yellow transparent to white turbid state, and finally returns to colorless transparent state, and then stir for 15 minutes. .

[0028] D. Add 0.3mmol (0.0228g) of thiourea to the above C solution, stir for 15 minutes to dissolve it completely, then transfer it to a 15mL reaction kettle, and heat it at 150°C for 21 hours to obtain water-soluble copper Indium Su...

Embodiment 3

[0032] Preparation of higher concentration copper indium sulfur (CuInS 2 ) quantum dot solution.

[0033] A. 0.40mmol copper dichloride (0.05379 grams) and 0.40mmol (0.1173 grams) indium trichloride tetrahydrate were dissolved in 10.5ml water, stirred for 15 minutes to obtain 2+ and In 3+ of aqueous solution.

[0034] B. Add 416 μL of 3-mercaptopropionic acid to the above solution at room temperature, and stir for 15 minutes to form small yellow particles, which can be more evenly dispersed in the aqueous solution.

[0035] C. Add NaOH solution to the solution obtained in step B to adjust the pH value to 11.2, the same as step C in Example 1.

[0036] D. Add 0.8mmol (0.0608g) thiourea to the above solution, stir for 20 minutes to dissolve it completely, transfer it to a 15mL reaction kettle, and heat at 150°C for 21 hours to obtain water-soluble CuInS 2 Quantum dots, the resulting quantum dot solution is a yellow transparent solution;

[0037] E. Add ethanol solution to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com