Preparation method of high-strength injectable polyphase calcium phosphate based bone cement

A technology of phase calcium phosphate and bone cement, applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of no osteoinductive activity, monomer toxicity, poor biological activity, etc., to promote osteoinductive ability, accelerate bone The effect of regeneration, repair and improvement of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

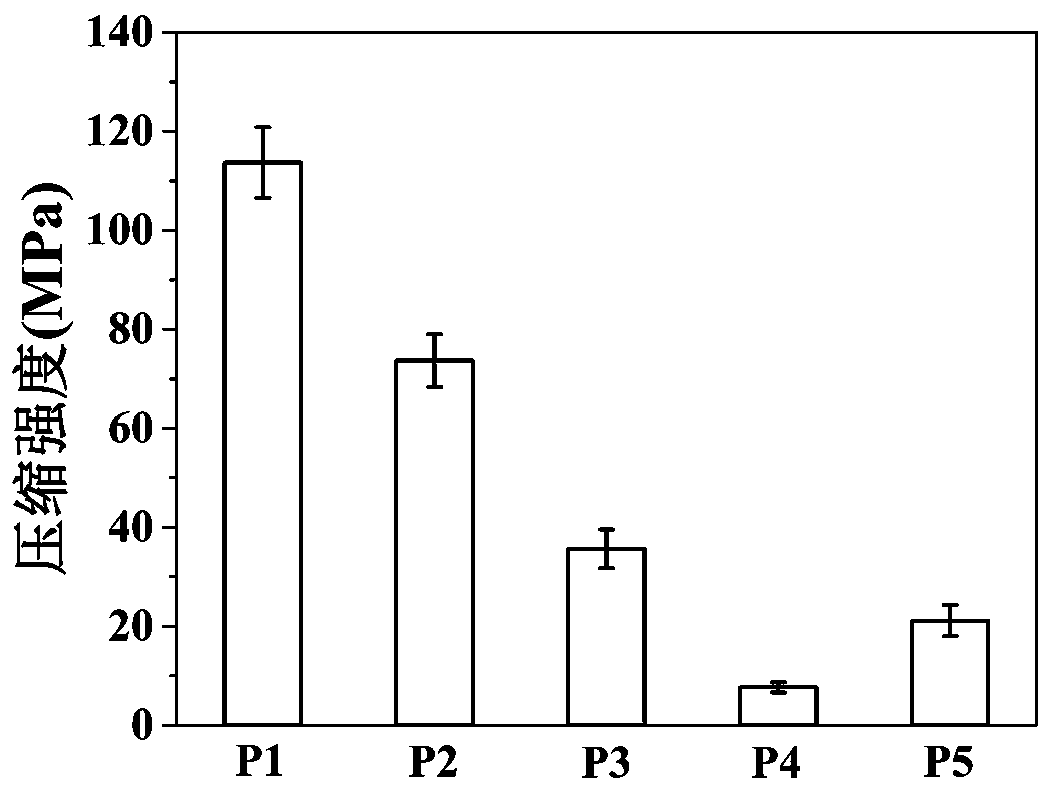

Examples

Embodiment 1

[0024] A preparation method of a high-strength injectable heterogeneous calcium phosphate-based bone cement, comprising the steps of:

[0025] 1) Mix α-tricalcium phosphate powder, calcium sulfate hemihydrate powder and bioactive glass powder as raw materials; calcium sulfate hemihydrate is obtained by heating calcium sulfate dihydrate at 100-150°C for 12-24 hours;

[0026] The preparation method of bioactive glass is as follows: first, take 1.8g of calcium nitrate tetrahydrate and join in 5 ml of ethyl orthosilicate, then, add 16 ml of deionized water and absolute ethanol with a molar ratio of 1:1 The mixed solution of, finally, adds 6g glacial acetic acid wherein again. The sol was reacted by stirring, and the prepared sol was dried in an oven at 60° C. for 12-24 hours to obtain a xerogel. The dry gel is placed in a muffle furnace, heated to 550-750° C. at a heating rate of 5-10° C. / min, kept for 2 hours, and cooled naturally to obtain the bioactive glass.

[0027] Among t...

Embodiment 2

[0033] A preparation method of a high-strength injectable heterogeneous calcium phosphate-based bone cement, comprising the steps of:

[0034] 1) Premix α-tricalcium phosphate powder, calcium sulfate hemihydrate powder and bioactive glass powder as raw materials; in the raw materials, the mass fractions of α-tricalcium phosphate, calcium sulfate hemihydrate and bioactive glass are 76wt %, 19wt% and 5wt%;

[0035] 2) Put the pre-mixed raw materials together with agate medium balls and absolute ethanol into a ball mill for ball milling; make the raw materials fully mixed evenly, and make the particle size of the raw materials uniform through ball milling; during ball milling, the raw materials, agate medium balls and no The water-ethanol mass ratio is 1: 30: 12, ball milling for 8-12 hours at a speed of 400-900 rpm.

[0036] 3) Take out the ball-milled wet material containing absolute ethanol, place it in an oven at 60-100°C and dry it for 5-10 hours to obtain bone cement powde...

Embodiment 3

[0040] A preparation method of a high-strength injectable heterogeneous calcium phosphate-based bone cement, comprising the steps of:

[0041] 1) Premix α-tricalcium phosphate powder, calcium sulfate hemihydrate powder and bioactive glass powder as raw materials; in the raw materials, the mass fractions of α-tricalcium phosphate, calcium sulfate hemihydrate and bioactive glass are 76wt %, 19wt% and 5wt%;

[0042] 2) Put the mixed raw materials together with agate medium balls and absolute ethanol into a ball mill for ball milling; mix the raw materials evenly, and make the particle size of the raw materials uniform through ball milling; during ball milling, the raw materials, agate medium balls and anhydrous Ethanol was ball milled for 8-12 hours at a mass ratio of 1: 30: 12 at a speed of 400-600 rpm.

[0043] 3) Take out the ball-milled wet material containing absolute ethanol, place it in an oven at 60-100°C and dry it for 5-10 hours to obtain bone cement powder;

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com