Process for manufacturing alpha-tricalcium phosphate-alpha-calcium sulfate hemihydrates bone cement porous bracket through squashing method

A technology of calcium sulfate hemihydrate and tricalcium phosphate, which is applied in the fields of medical science, tissue regeneration, prosthesis, etc., can solve the problems of low uniformity of porosity, inability to mass production, complicated steps, etc., and is suitable for mass production, Reduce the effect of simple preparation and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of α-TCP powder:

[0028] Weigh the calcium hydrogen phosphate powder and the calcium carbonate powder according to the molar ratio of 2:1, use an appropriate amount of absolute ethanol as the medium for wet ball milling, the rotation speed is 400rpm, the ball milling time is 4h, and the mass ratio of ball milling beads to powder is 3:1. The raw material mixture was removed from ethanol by rotary evaporation, and dried in an oven at 60 °C for 24 h. The dried powder is placed in a muffle furnace, calcined at 1400°C for 2 hours, taken out, and rapidly cooled in a blast environment. The cooled powder was wet ball milled with anhydrous ethanol as the medium, the rotation speed was 400 rpm, the ball milling time was 6 h, and the mass ratio of ball milling beads to powder was 4:1. The powder suspension was fully dried in an oven at 80° C. to prepare α-TCP powder.

[0029] (2) Preparation of α-CSH:

[0030] Put 50g of calcium sulfate dihydrate in 150mL of di...

Embodiment 2

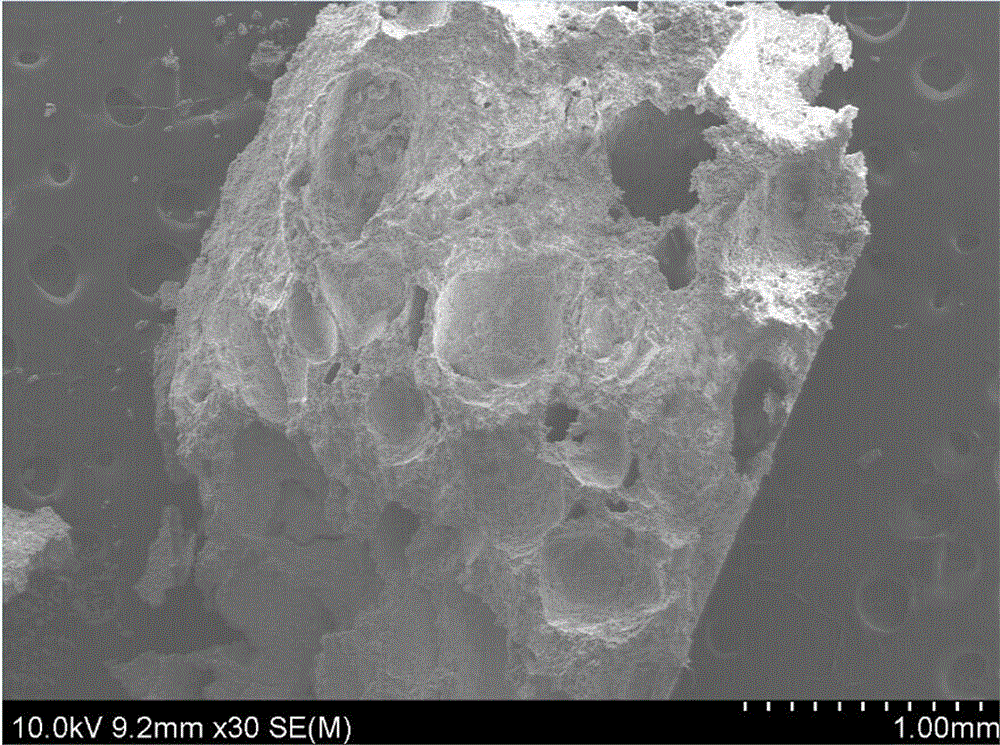

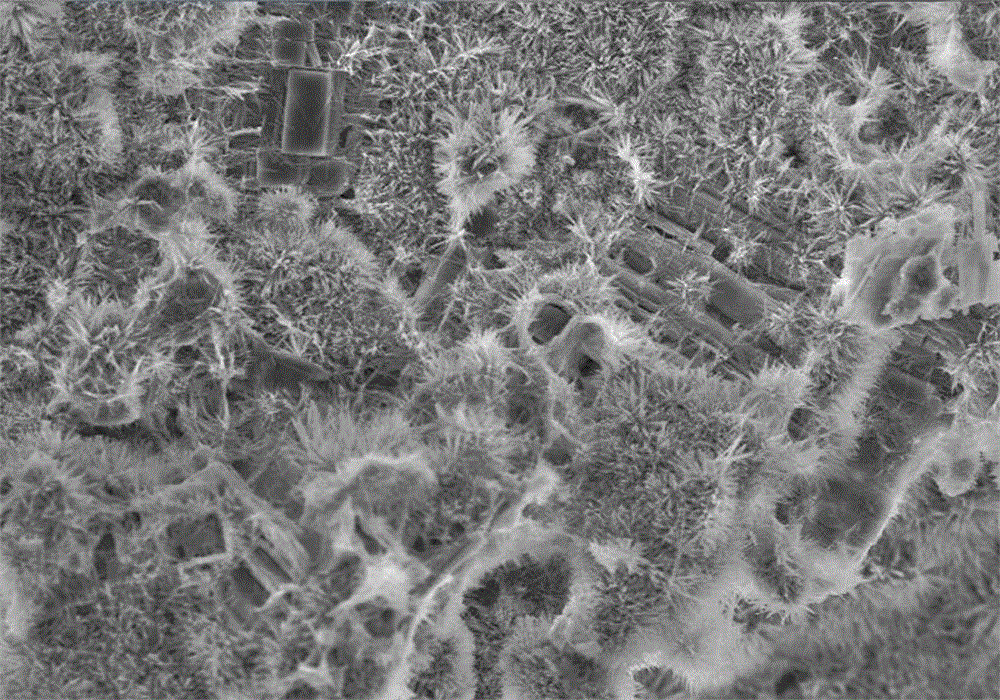

[0032] Mix the α-TCP and α-CSH powders prepared in Example 1 at a mass ratio of 7:3, and then mix them with salt particles with a particle size of 100-300 μm at a mass ratio of 5:5 to obtain a bone cement powder, which is placed in A cylindrical mold with a diameter of 6 mm was fully compacted with a tablet press, and after demoulding, it was soaked in a water bath at 37°C for 24 hours to remove salt particles, and a bone cement porous scaffold was obtained. The results of the SEM scanning electron microscope are as follows: figure 1 , figure 2 As shown, the measured porosity is 46%, and the compressive strength is 10MPa.

Embodiment 3

[0034] Mix the α-TCP and α-CSH powders prepared in Example 1 at a mass ratio of 7:3, and then mix them with salt particles with a particle size of 100-300 μm at a mass ratio of 3:7 to obtain a bone cement powder, which is placed in A cylindrical mold with a diameter of 6 mm was fully compacted with a tablet press, and after demoulding, it was soaked in a water bath at 37°C for 24 hours to remove salt particles, and a bone cement porous scaffold was obtained. The measured porosity is 83%, and the compressive strength is 5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com