Biphase tricalcium phosphate white phosphor as well as in-situ synthesis method and application thereof

A biphasic tricalcium phosphate white, in-situ synthesis technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of complex process, large equipment investment, process pollution, etc. Small investment, no effect of process pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

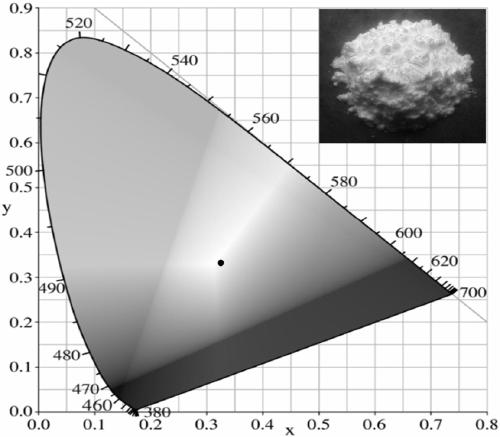

[0031] An in-situ synthesis method of biphasic tricalcium phosphate white fluorescent powder, comprising the following steps: using a compound containing calcium ions, a compound containing phosphorus or calcium-phosphorus ions, and a compound containing europium ions as raw materials, according to the general chemical formula Ca 3-x Eu x (PO 4 ) 2 The molar ratio of each element in the method weighs the raw materials, grinds and mixes them evenly, and then calcines them at high temperature in an oxygen-rich atmosphere (such as air or oxygen or other oxygen-rich atmospheres). The calcination temperature is 1100-1650°C and the calcination time is 0.5-24 hours. , and finally, in situ synthesis of Eu by a controlled cooling process 2+ and Eu 3+ The color coordinates of the co-activated biphasic calcium tricalcium phosphate white phosphor are (0.287-0.345, 0.297-0.360).

[0032] Further, the compound containing calcium ion is calcium carbonate (CaCO 3 ), calcium bicarbonate (...

Embodiment 1

[0039] Preparation of Ca 2.97 Eu 0.03 (PO 4 ) 2 Biphasic tricalcium phosphate white phosphor

[0040] According to the chemical formula Ca 2.97 Eu 0.03 (PO 4 ) 2 The stoichiometric ratio of each element in the 3 : 0.971 g, europium oxide Eu 2 o 3 : 0.053 g, calcium hydrogen phosphate CaHPO 4 2H 2 O: 3.442 grams, ground and mixed in an agate mortar, then calcined in an air atmosphere at a temperature of 1400°C, and calcined for 5 hours. The cooling rate is rapidly cooled to room temperature, and then pulverized and ground to obtain Eu 2+ and Eu 3+ Co-activated biphasic calcium tricalcium phosphate white phosphor.

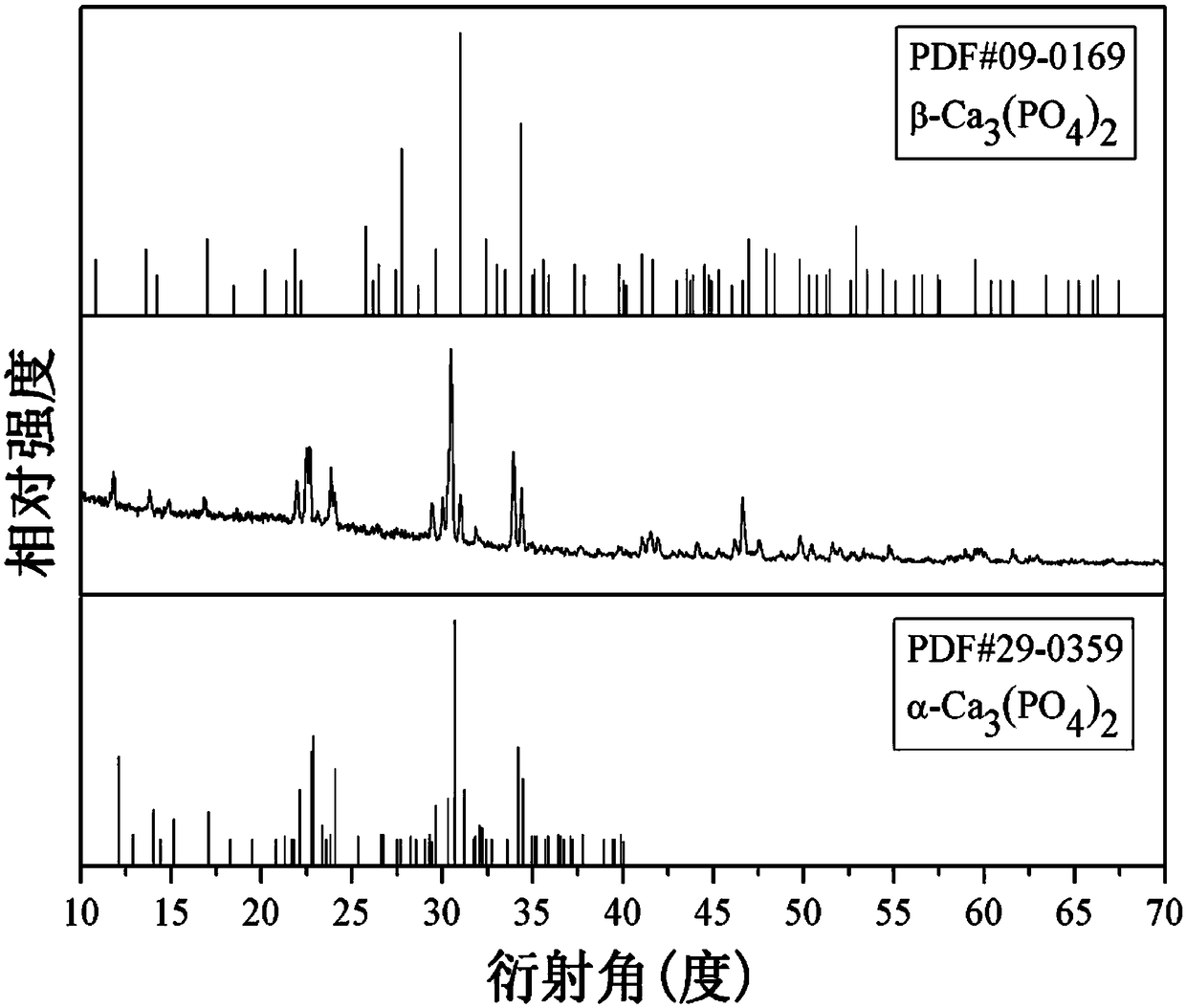

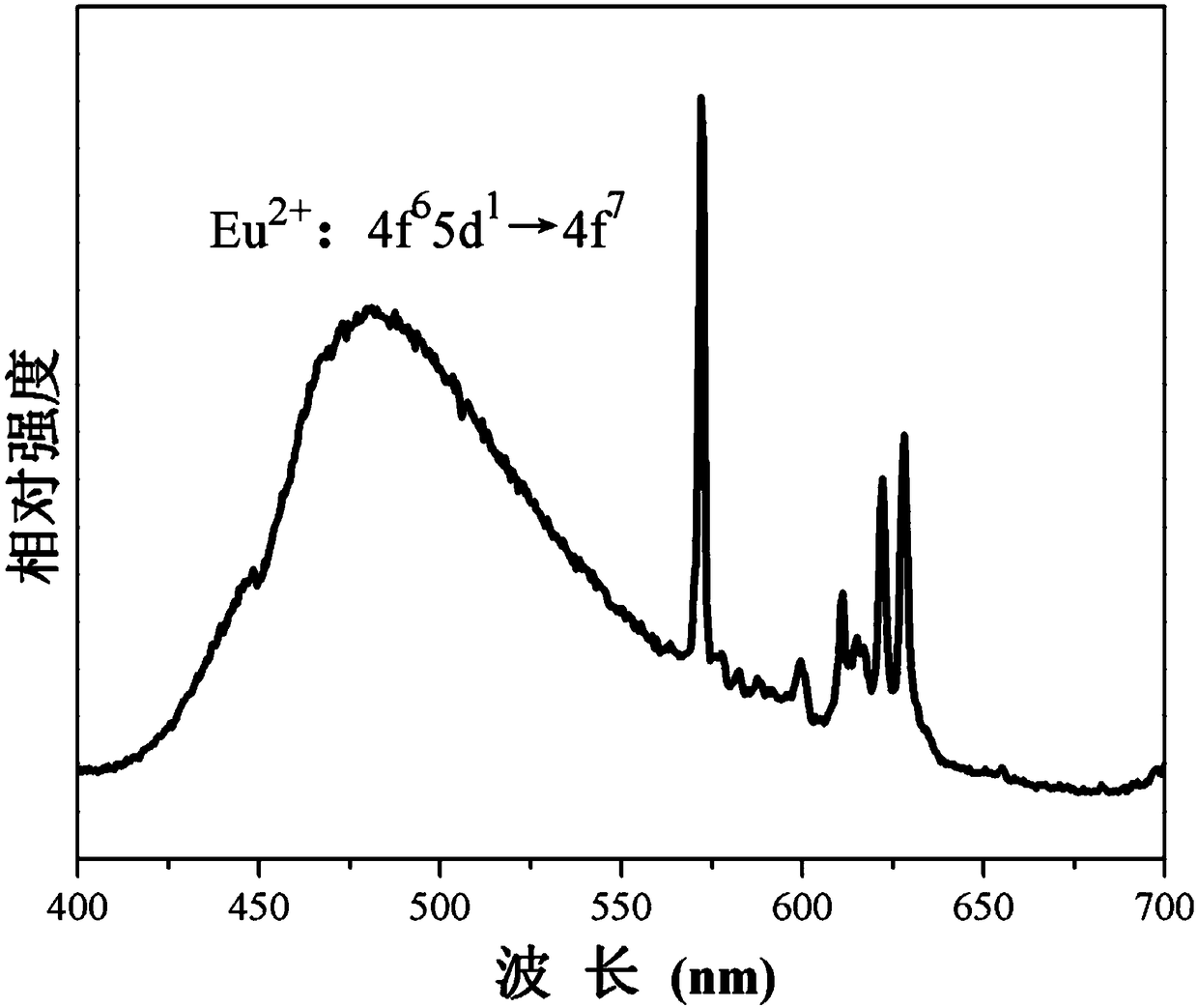

[0041] figure 1 The Ca prepared according to the technical scheme of this embodiment is given 3-x Eu x (PO 4 ) 2 The X-ray powder diffraction pattern of the α-tricalcium phosphate standard card PDF#290359 and the β-tricalcium phosphate standard card PDF#090169 are relatively visible. The prepared white phosphor is a single-component biphasic trical...

Embodiment 2

[0044] Preparation of Ca 2.94 Eu 0.06 (PO 4 ) 2 Biphasic tricalcium phosphate white phosphor

[0045] According to the chemical formula Ca 2.94 Eu 0.06 (PO 4 ) 2 The stoichiometric ratio of each element in the 3 : 0.941 g, europium oxide Eu 2 o 3 : 0.106 g, calcium hydrogen phosphate CaHPO 4 2H 2 O: 3.442 grams, ground and mixed in an agate mortar, then calcined in an air atmosphere at a temperature of 1400°C, and calcined for 5 hours. The speed is rapidly cooled to room temperature, and then pulverized and ground to obtain Eu 2+ and Eu 3+ Co-activated biphasic tricalcium phosphate white phosphor, in which α- and β-Ca 3-x Eu x (PO 4 ) 2 The two phase contents were 66% and 34%, respectively. Using 365nm near-ultraviolet light as the excitation light source, the biphasic tricalcium phosphate emits white light, and the CIE color coordinates are x=0.335, y=0.345, and can be used as LED white fluorescent powder and bioluminescent marker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com