Method of preparing alpha-tricalcium phosphate through low temperature calcining

A tricalcium phosphate, low-temperature calcination technology, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., can solve problems such as long solidification time and poor mechanical properties of α-tricalcium phosphate, Achieve low cost, low energy consumption and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

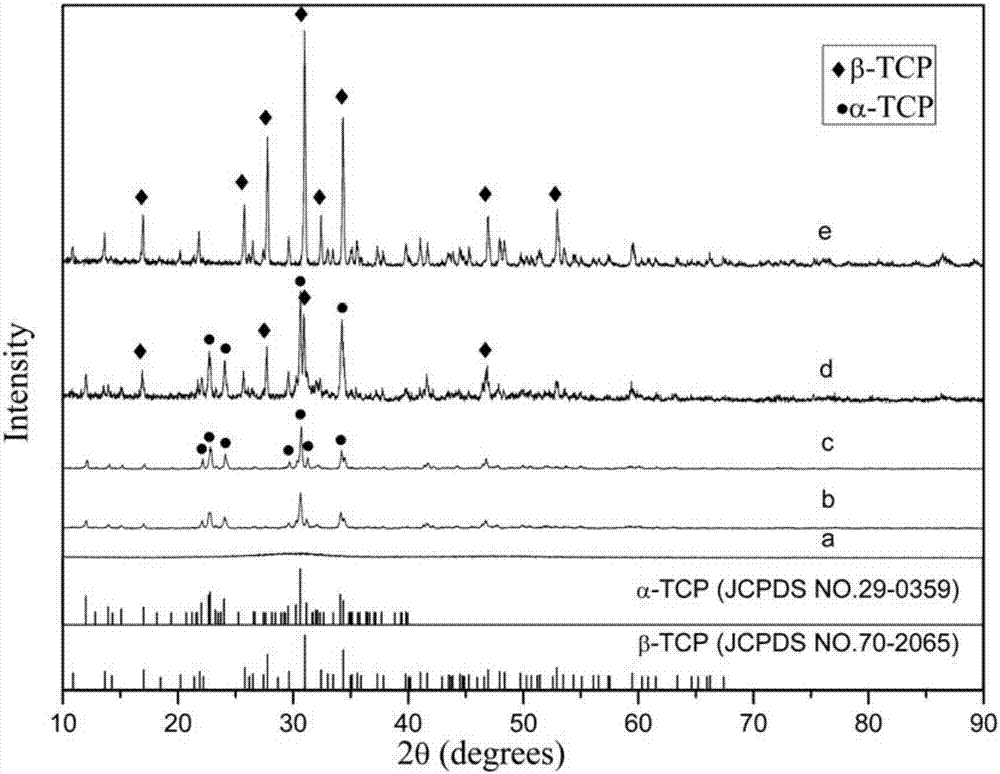

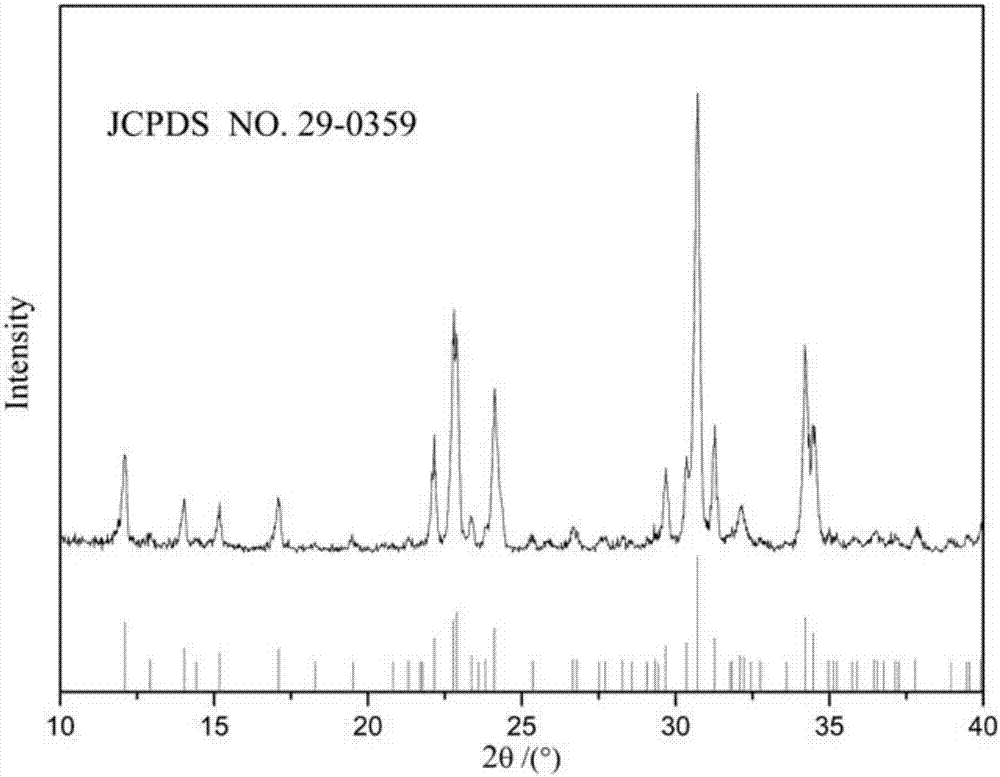

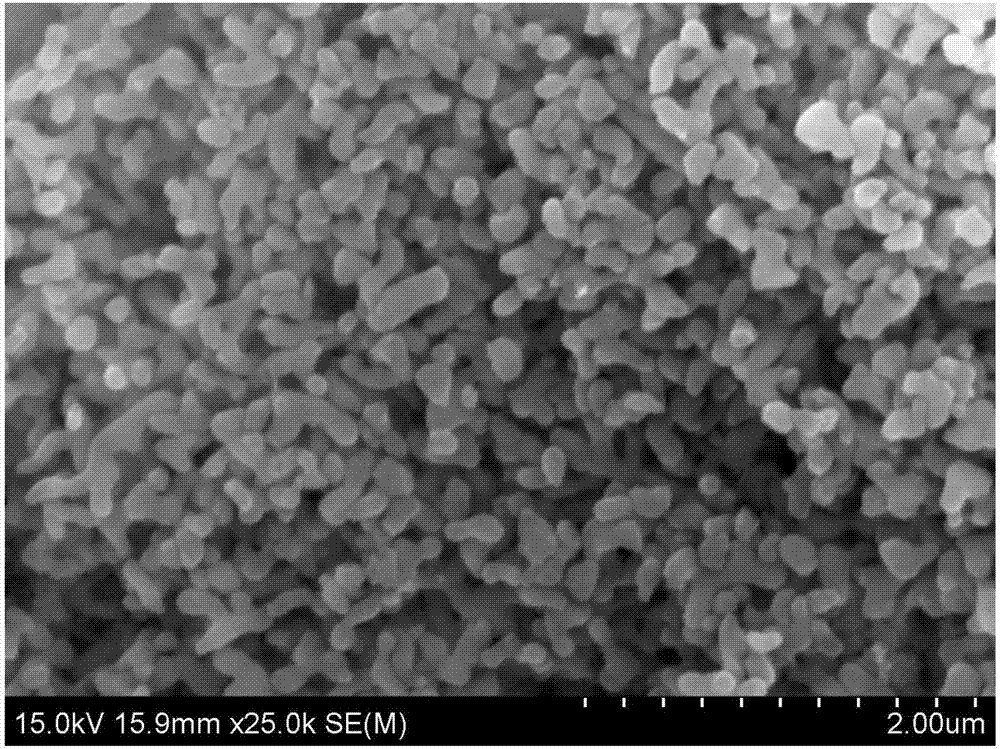

Embodiment 1

[0035] Take 20g of β-cyclodextrin, prepare 1L of β-cyclodextrin saturated solution, and then weigh 47.2g of Ca(NO 3 ) 2 4H 2 O was dissolved in the above saturated solution of β-cyclodextrin to obtain Ca 2+ A solution with a concentration of 0.2mol / L was placed in an environment of 25°C for 24 hours; weighed 17.6g (NH 4 ) 2 HPO 4 Prepare 1L PO 4 3- Concentration is the solution of 0.133mol / L; Will (NH 4 ) 2 HPO 4 The solution was added dropwise to the Ca(NO 3 ) 2 4H 2 In the mixed solution of O and β-cyclodextrin, keep stirring, and adjust the pH of the reaction solution with ammonia water to keep it between 10-11. After the addition is completed, continue to stir and react for half an hour. The whole process is at 25°C. environment. After the reaction was completed, the obtained suspension was subjected to suction filtration, washed with distilled water and absolute ethanol during the suction filtration, and ventilated and dried at room temperature for 16 hours t...

Embodiment 2

[0038] Get 5g β-cyclodextrin, prepare 250ml of β-cyclodextrin saturated solution, then weigh 11.8g of Ca(NO 3 ) 2 4H 2 O was dissolved in the above saturated solution of β-cyclodextrin to obtain Ca 2+ For a solution with a concentration of 0.2mol / L, place the solution in an environment of 20°C for 24 hours; weigh 4.4g (NH 4 ) 2 HPO 4 Prepare 250ml PO 4 3- Concentration is the solution of 0.133mol / L; Will (NH 4 ) 2 HPO 4 The solution was added dropwise to the Ca(NO 3 ) 2 4H 2 In the mixed solution of O and β-cyclodextrin, keep stirring, and adjust the pH of the reaction solution with ammonia water to keep it between 10-11. After the dropwise addition is completed, continue to stir and react for half an hour. The whole process is at 20°C. environment. After the reaction was completed, the obtained suspension was subjected to suction filtration, washed with distilled water and absolute ethanol during the suction filtration, and ventilated and dried at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com