Preparation method capable of monitoring degraded bone cement with NIRII region fluorescent light, degraded bone cement product and application of degraded bone cement product

A technology of bone cement and fluorescence, which is applied in pharmaceutical formulations, pharmaceutical sciences, prostheses, etc., can solve problems such as easy transfer to bone tissue, and achieve the effects of improved injectability, simple raw materials, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

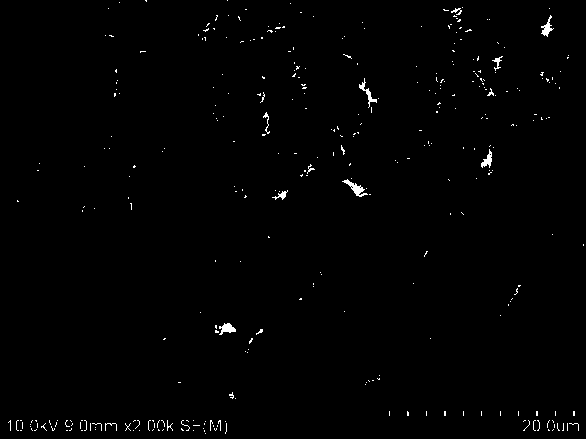

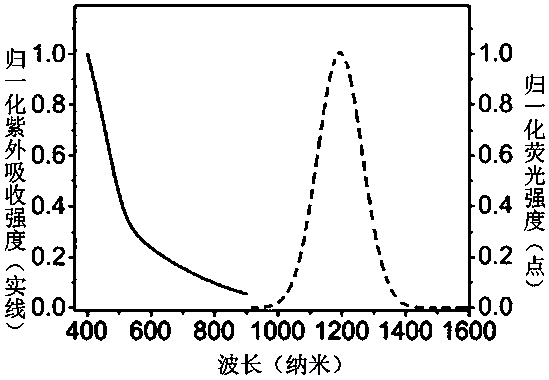

[0027] A kind of degradable bone cement that can be monitored by fluorescence in the NIRII area, with alpha-tricalcium phosphate, hydroxyapatite, and calcium sulfate hemihydrate as the solid part of the main bone repair components, adding hydroxypropyl methylcellulose, phosphorylated shell Glycans, gelatin biocompatible macromolecular components; the other part is modified Ag 2 S quantum dots, and the solution part is sodium hydrogen phosphate solution, prepared according to the following steps:

[0028] PEI-coated Ag 2 Preparation of S quantum dots: In a 200ml flask, add 0.2mmol Ag +ion and 0.8mmol PEI, and configure 20ml ultrapure water, stir the mixed solution under nitrogen and room temperature for 30 minutes to form PEI-Ag (+1 valence) complex, then, add 2ml 0.025mmol S-N 2 h 4 h 2 O aqueous solution was added to the above solution to obtain a brown solution, which was kept stirring for 30 minutes. After the reduction was completed, isopropanol was added to precipita...

Embodiment 2

[0034] A NIRII zone fluorescence monitorable degradable bone cement, Ag wrapped in PEI 2 The preparation of S quantum dots is the same as in Example 1, and is prepared according to the following steps:

[0035] Disperse alpha-tricalcium phosphate and calcium sulfate hemihydrate into a 40g / L solution in absolute ethanol, mix at 400rpm and carry out liquid phase grinding for 4h, then add 0.5% gelatin, continue ball milling in a ball mill for 15min, and the resulting solution Bone cement powder was obtained after rotary evaporation.

[0036] Weigh 0.1g of phosphorylated chitosan, 0.15g of gelatin, and 0.1g of hydroxypropyl methylcellulose, dissolve them in 19.65g of sodium hydrogen phosphate solution, and then add 40mg of PEI-wrapped Ag in the solution. 2 S quantum dots were uniformly mixed by ultrasound to prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan, 1.5% gelatin, 1% hydroxypropyl methylcellulose and 0.04% PEI-coated Ag 2 Bone cement solidification soluti...

Embodiment 3

[0039] A NIRII zone fluorescence monitorable degradable bone cement, Ag wrapped in PEI 2 The preparation of S quantum dots is the same as in Example 1, and is prepared according to the following steps:

[0040] Disperse alpha-tricalcium phosphate and calcium sulfate hemihydrate into a 40g / L solution in absolute ethanol, mix at 400rpm and carry out liquid phase grinding for 4h, then add 0.5% gelatin, continue ball milling in a ball mill for 15min, and the resulting solution Bone cement powder was obtained after rotary evaporation.

[0041] Weigh 0.1g of phosphorylated chitosan, 0.15g of gelatin, and 0.1g of hydroxypropyl methylcellulose, dissolve them in 19.65g of sodium hydrogen phosphate solution, and then add 100mg of PEI-wrapped Ag in the solution. 2 S quantum dots were uniformly mixed by ultrasound to prepare 20% sodium hydrogen phosphate, 1% phosphorylated chitosan, 1.5% gelatin, 1% hydroxypropyl methylcellulose and 0.1% PEI-coated Ag 2 Bone cement solidification soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com