Calcining defluorination method in feed-grade tricalcium phosphate production

A tricalcium phosphate, feed-grade technology, applied in the field of phosphate, can solve the problems of low output, unstable product quality, high production cost, etc., and achieve the effects of stable fluorine content index, remarkable defluorination effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] During production, the ingredients are counted as mass fraction: P 2 o 5 Content 15%~50%, CaO 30%~60%, MgO≤5%, SiO 2 ≤20%, Pb≤100×10 -6 、Cd≤100×10 -6 、As≤100×10 -6 , (Al 2 o 3 +Fe 2 O) ≤10.0%, with a moisture content of about 45%; the wet phosphate rock powder whose particle size is controlled to be ≤10mm is lifted by the bucket elevator, metered by the metering belt into the dryer, and countercurrent dried at a drying temperature of 900°C ; After drying, the moisture content of phosphate rock powder is controlled to be ≤5%. The dried phosphate rock powder and sodium salt composed of soda ash, Glauber's salt and sodium chloride are metered into the ball mill for mixing and ball milling according to the ratio requirements, and the powder obtained after mixing is sent to the granulator. Phosphoric acid is granulated at a ratio of 0.25:0.80:0.25.

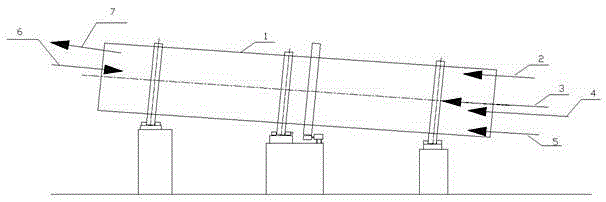

[0016] The granulated material enters the rotary calcination kiln from the tail; the primary air and secondary air ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com